Manufacturing process of sealed negative pressure drainage wet sponge

A negative pressure drainage and manufacturing process technology, applied in the field of medical sponges, can solve problems such as the increase of reducing substances, the destruction of molecular cross-linking points, the inability to meet the biosafety requirements of deep cavity wounds, etc., achieving high biosafety and speeding up healing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of embodiment 1 polyvinyl alcohol sponge 3 is as follows:

[0034] Mix 1 kg of 10% wt polyvinyl alcohol aqueous solution and 10 ml of formaldehyde under acidic conditions in a reactor at a temperature of 15 to 25 ° C and a stirring rate of 200 to 300 RPM for 6 to 30 minutes, then stir at a stirring rate of 100 Stir for 2-10 minutes at ~200RPM, add a cross-linking agent, and cure at 50-85°C for 12-48 hours; cut the prepared sponge, wash it, and dry it using a microwave drying process at a vacuum degree of -0.5~ 1MPa, the temperature is -30~50℃, and the time is 1~3h.

Embodiment 2

[0036] The manufacturing process of the sealed negative pressure drainage wet sponge comprises the following steps:

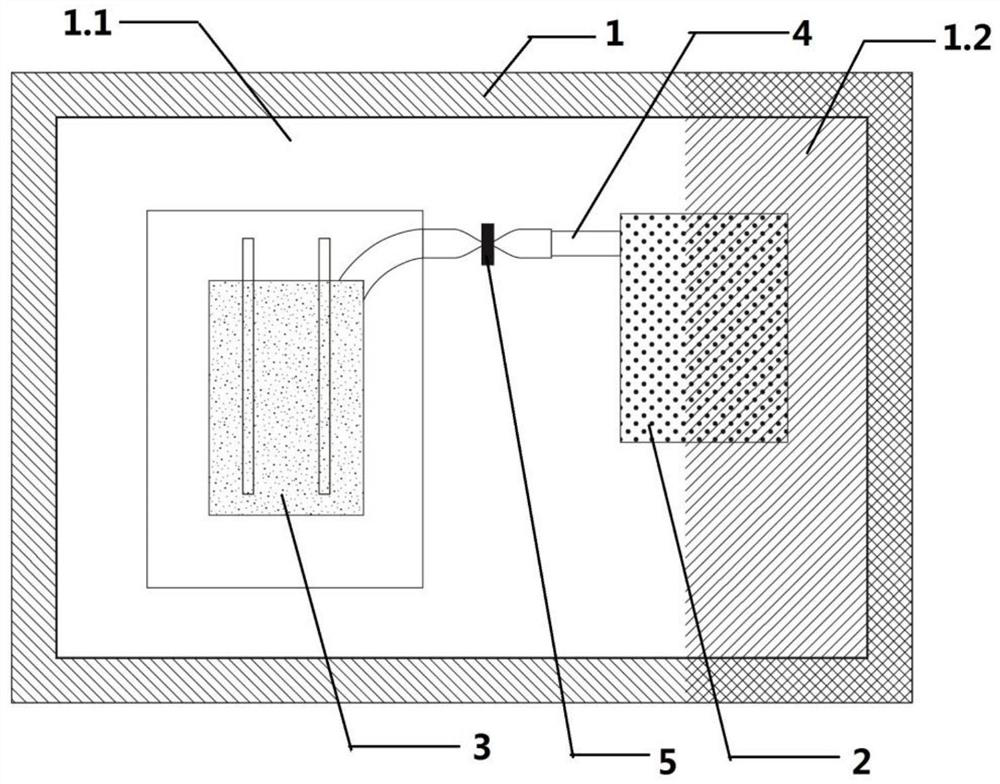

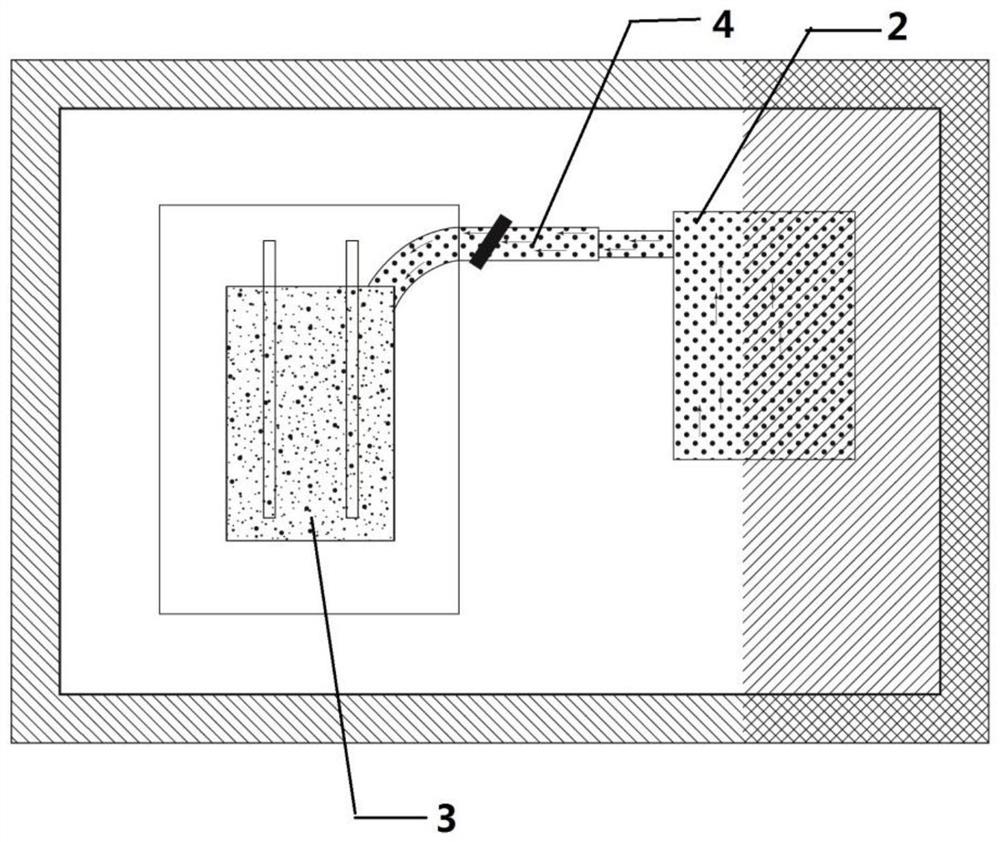

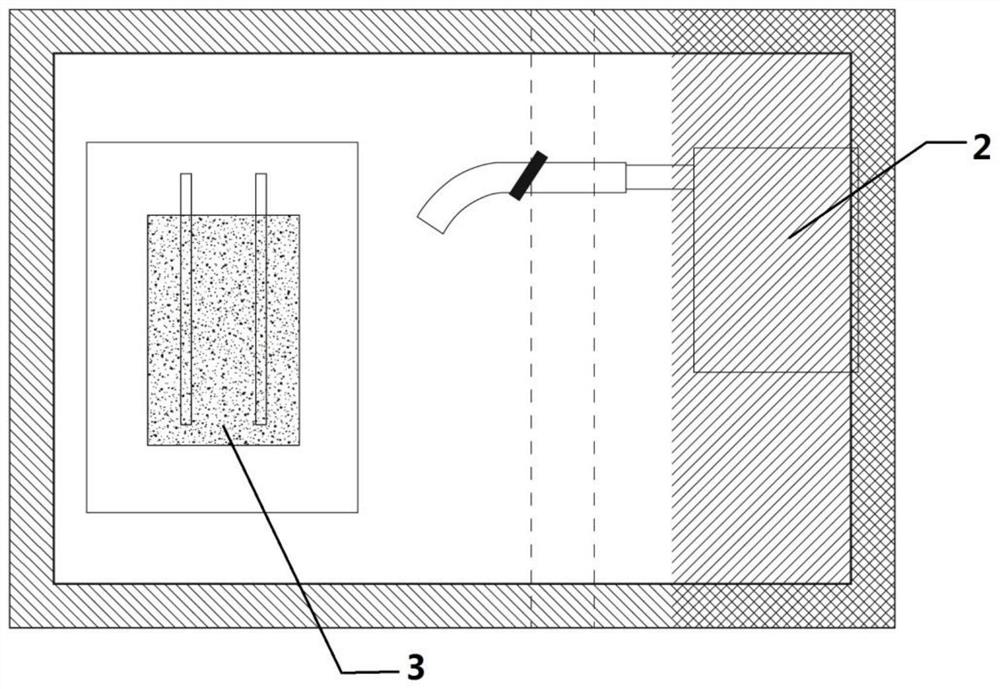

[0037] 1) Sterilization: put the dry polyvinyl alcohol sponge 3 into the head bag 1, and connect the head bag 1 with the liquid storage chamber 2 through the connecting pipe 4, and seal it; then put the polyvinyl alcohol sponge 3 into Header bag 1 is sent into an environment containing ethylene oxide gas, and ethylene oxide gas enters the pair of polyvinyl alcohol sponges 3 of header bag 1 through the hole on the Tyvek paper 1.2 surface of header bag 1, and the temperature is 50°C. Fumigate and sterilize for 4 hours, and then stand still in a ventilated environment; wherein, one side of the plug bag 1 is transparent plastic 1.1, and the other side is made of transparent plastic 1.1 and Tyvek paper 1.2, and Tyvek paper 1.2 is the plug the upper part of one side of bag 1;

[0038] 2) Rehydration: Put the sterilized product in sealed packaging, and put it outside...

Embodiment 3

[0040] The manufacturing process of the sealed negative pressure drainage wet sponge comprises the following steps:

[0041] 1) Sterilization: put the dry polyvinyl alcohol sponge 3 into the head bag 1, and connect the head bag 1 with the liquid storage chamber 2 through the connecting pipe 4, and seal it; then put the polyvinyl alcohol sponge 3 into Header bag 1 is sent into an environment containing ethylene oxide gas, and ethylene oxide gas enters the pair of polyvinyl alcohol sponges 3 of header bag 1 through the hole on the Tyvek paper 1.2 surface of header bag 1, and the temperature is 45°C. Fumigate and sterilize for 4 hours, and then stand still in a ventilated environment; wherein, one side of the header bag 1 is made of transparent plastic 1.1, and the other side is made of transparent plastic 1.1 and Tyvek paper 1.2, and the Tyvek paper 1.2 is the header bag 1 the middle of one side;

[0042] 2) Rehydration: Put the sterilized product in sealed packaging, and put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com