Biomedical grinding equipment

A biomedicine and equipment technology, applied in grain processing, solid separation, sieving, etc., can solve the problems of small grinding volume, reduced grinding efficiency, and difficulty in obtaining usage requirements, so as to improve work efficiency, improve screening ability, and avoid wandering around. spill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

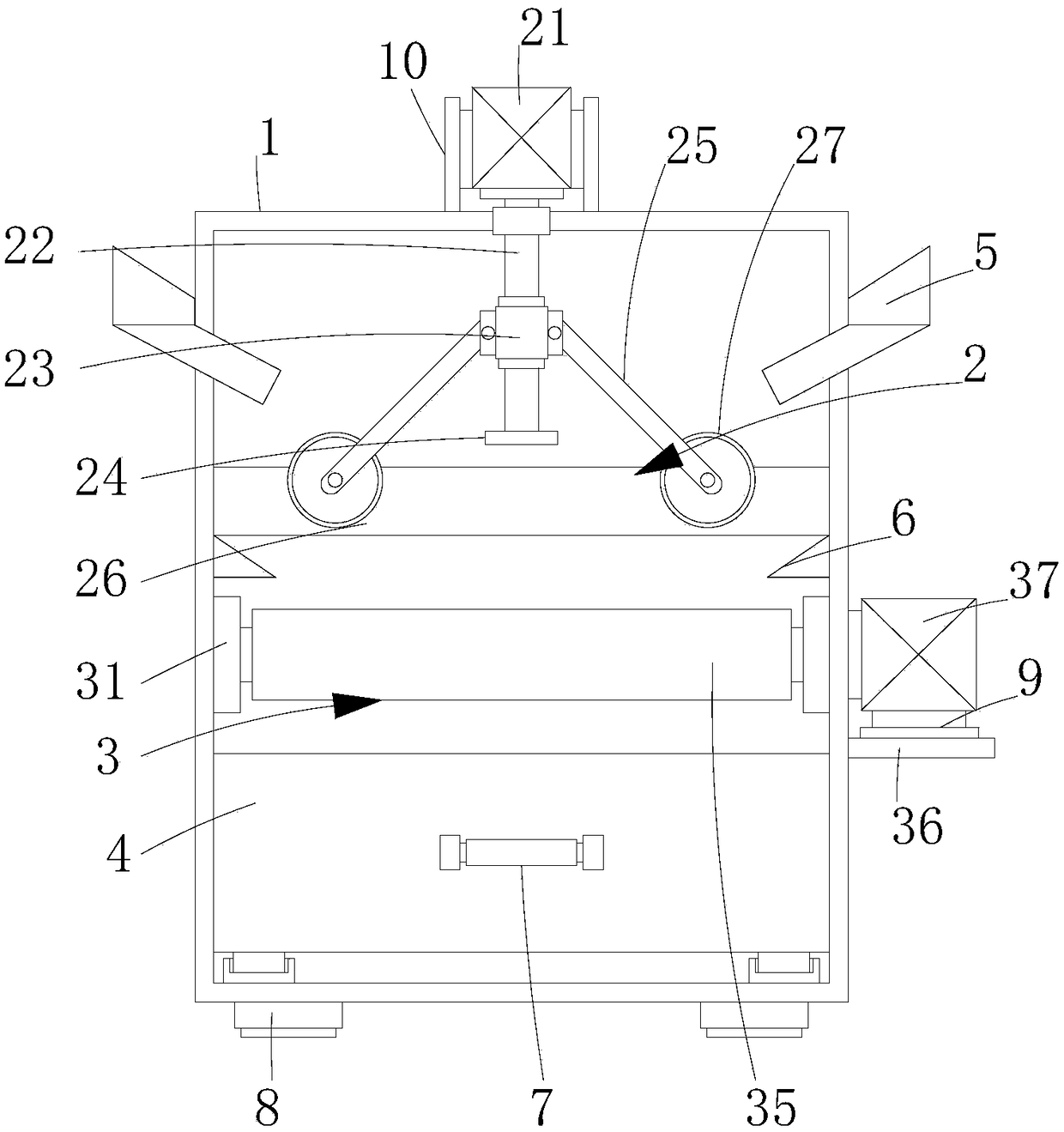

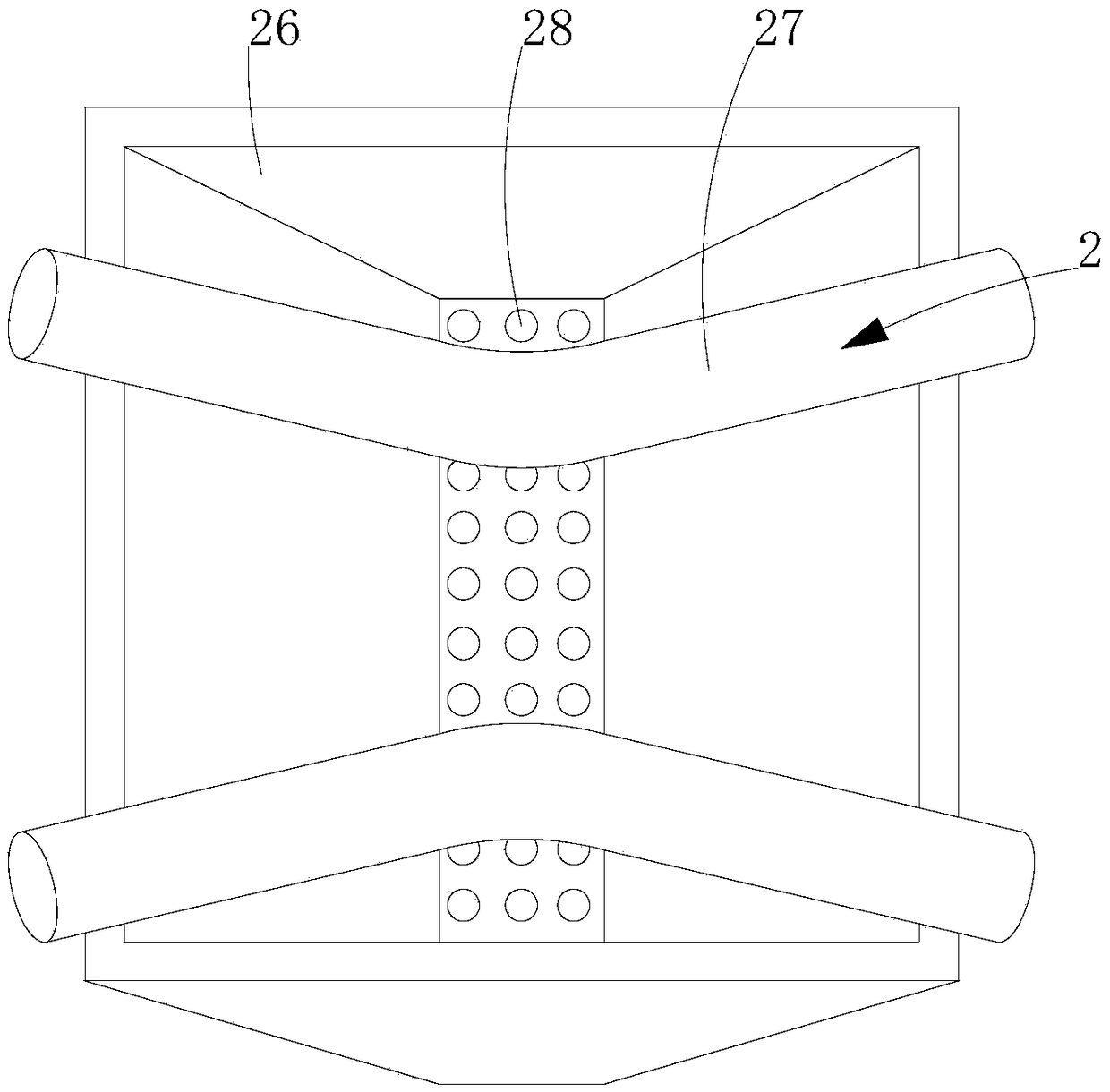

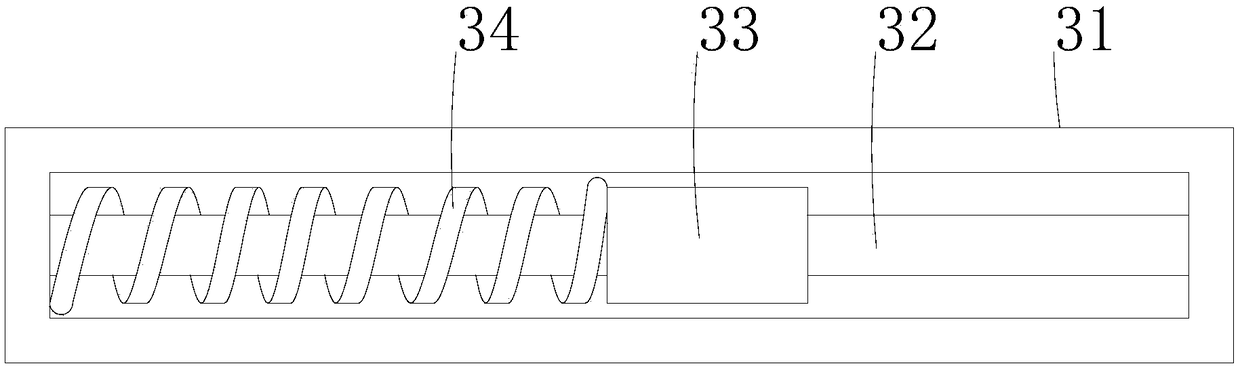

[0026] Such as Figure 1-4 As shown, the present invention provides a technical solution: a biomedical grinding equipment, comprising a chassis 1, a grinding mechanism 2 and a screening mechanism 3. The grinding mechanism 2 is located above the interior of the cabinet 1, and the screening mechanism 3 is located in the middle of the interior of the cabinet 1. , The bottom of the inner wall of the chassis 1 is movably connected with the bottom of the collection box 4, and the top of the collection box 4 is located below the bottom of the screening mechanism 3. The tops of both sides of the chassis 1 are provided with feed pipes 5, and both sides of the inner wall of the chassis 1 are The guide plate 6 is fixedly connected, and the guide plate 6 is located below the grinding mechanism 2, the bottom of the guide plate 6 is located above the top of the screening mechanism 3, the middle position of the front of the collection box 4 is fixedly connected with a handle 7, and the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com