Forming method for large multi-rib disc-shaped forged piece

A basin-shaped, large-scale technology, applied in the field of forging and forming, can solve the problems of gnawing and filling of ribs, and achieve the effect of increasing metal fluidity, reducing deformation resistance, and eliminating gnawing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

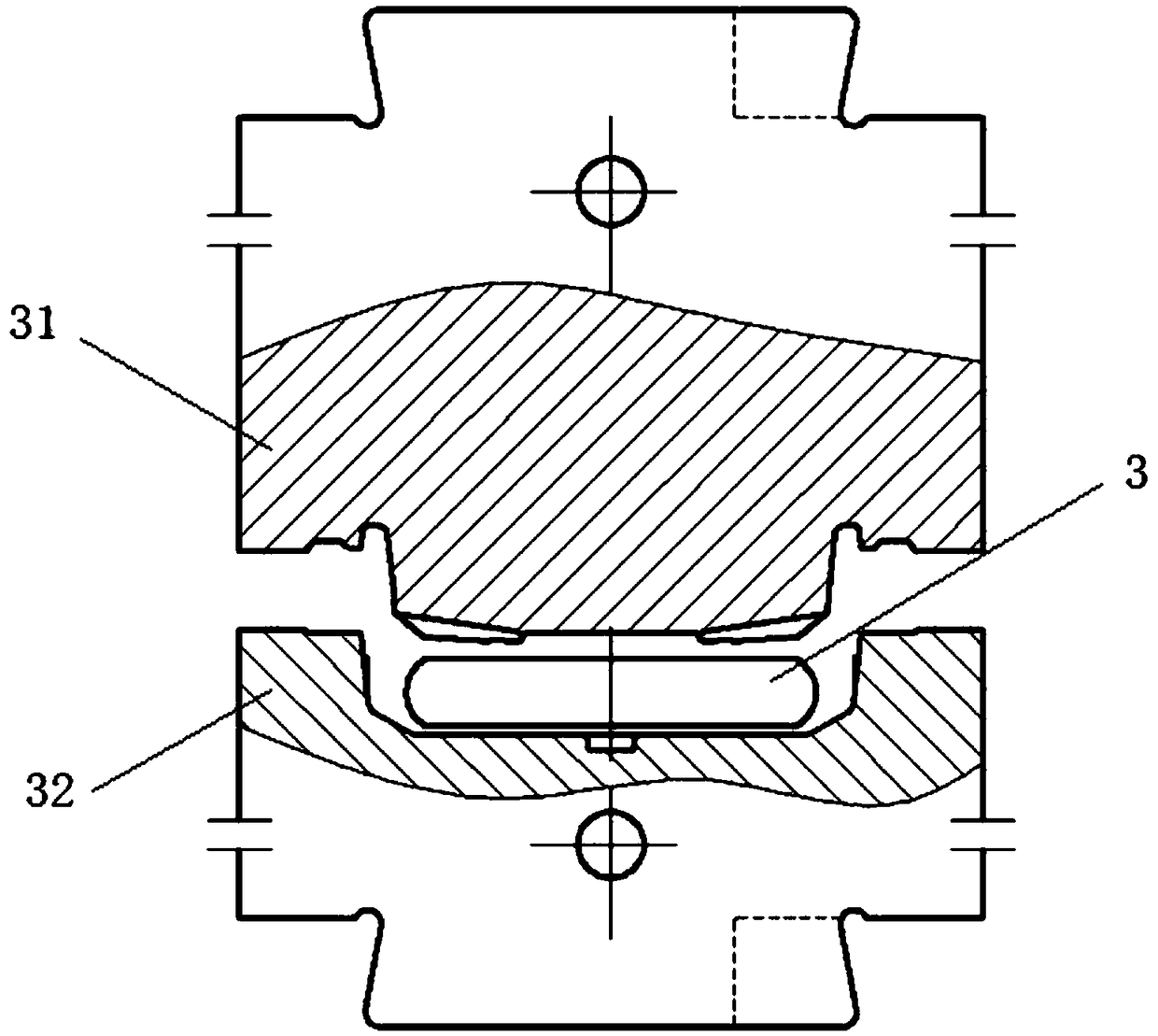

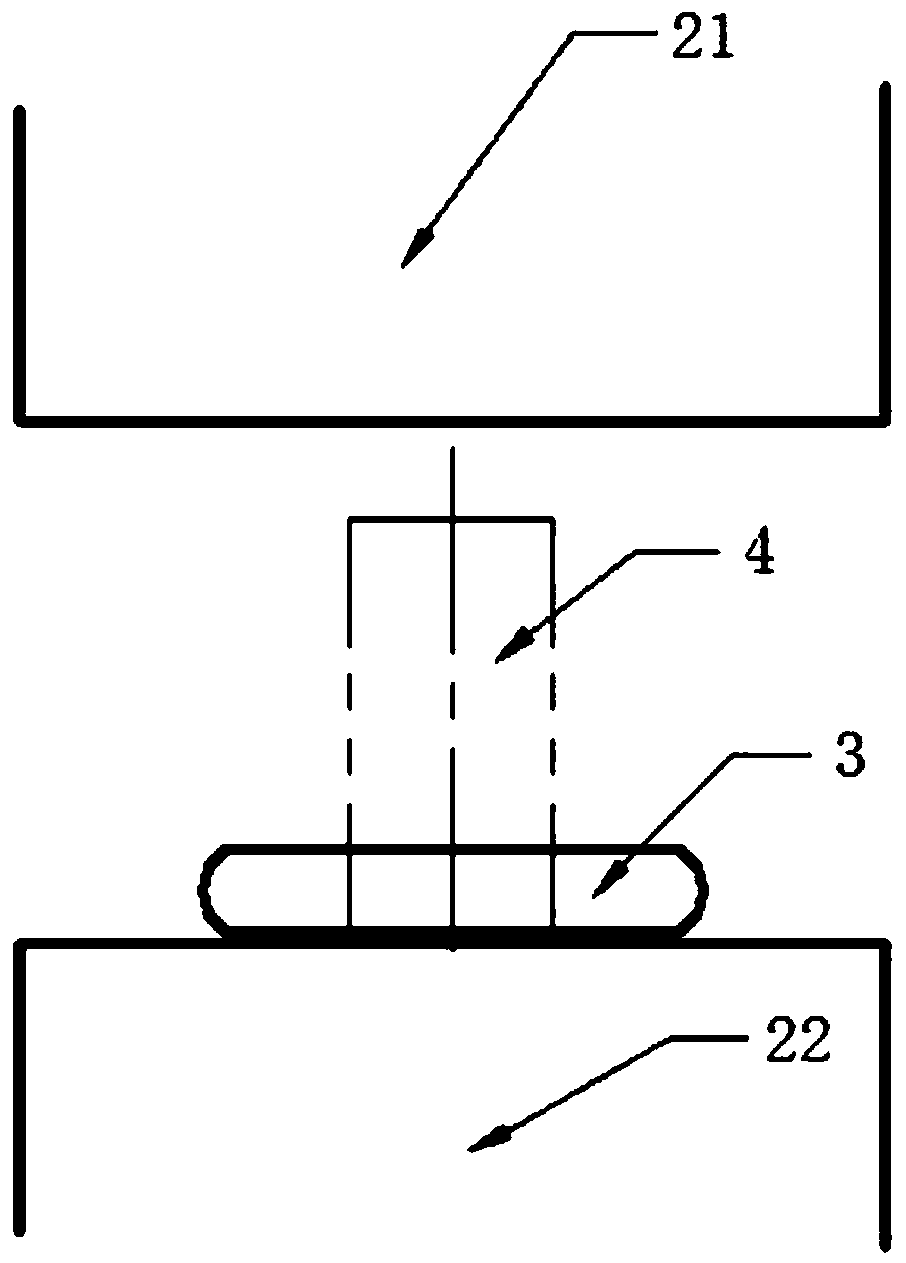

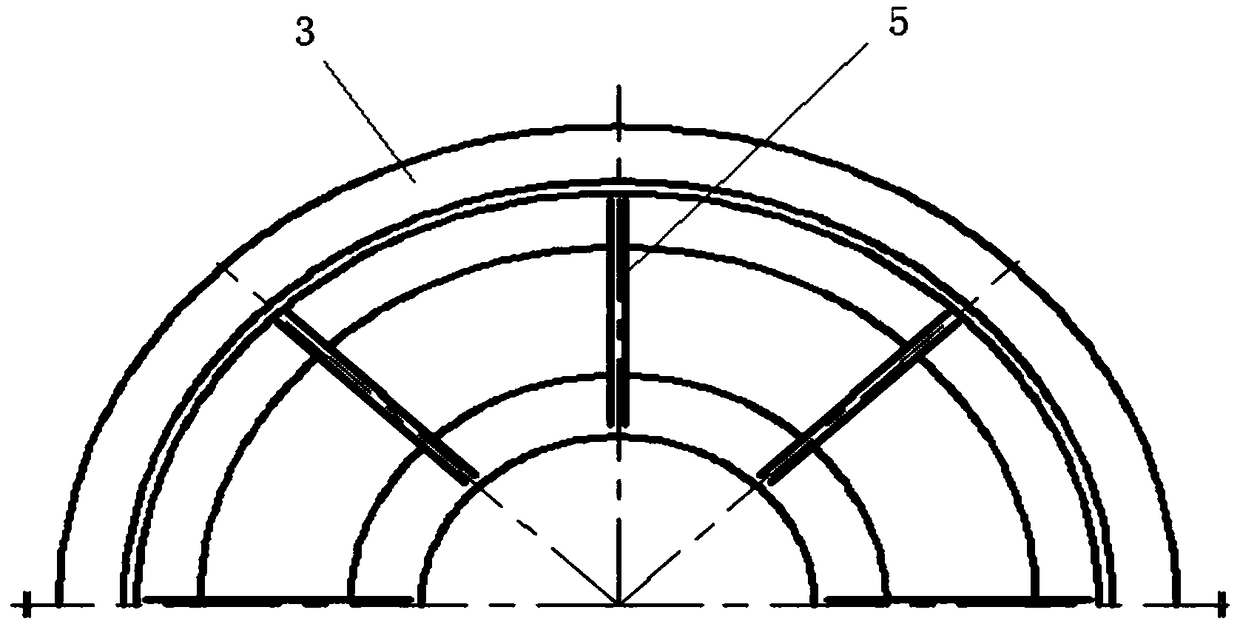

[0030] like Figure 1-7 As shown, the height of the large multi-rib basin-shaped forging is 66.4 mm, and the inner bottom surface is provided with eight narrow ribs 5. The forging die includes an upper die 1 and a lower die 2, and the lower die 2 is provided with eight forming grooves 6. The ribs 5 are formed in the forming groove 6 of the lower die 2, and the cavity depth of the upper die 1 is 11.4 mm larger than the height of the large multi-rib basin-shaped forging; the center of the lower die 2 is provided with a crescent-shaped positioning groove 7. The inner wall of the upper mold 1 has a draft angle of 6°, the outer wall of the lower mold 2 has a combined draft angle of 3° and 6°, and the height of the 6° draft angle of the outer wall of the lower mold 2 is 40mm.

[0031] The forming method of large multi-rib basin-shaped forgings is formed by closed die forging, which specifically includes the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Ellipticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com