Laser swing welding system

A welding system and laser welding head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reducing the accuracy requirements of workpieces, and achieve the effects of reducing accuracy requirements, improving welding efficiency, and diversifying welding angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

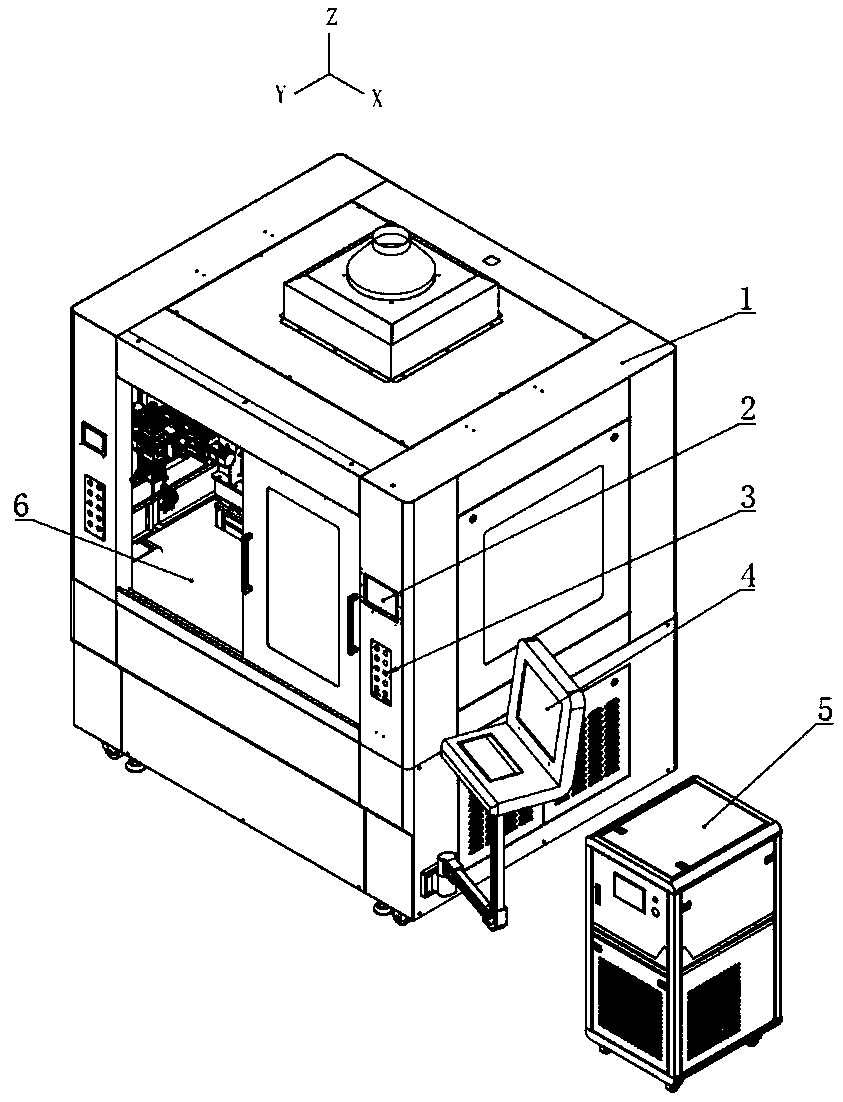

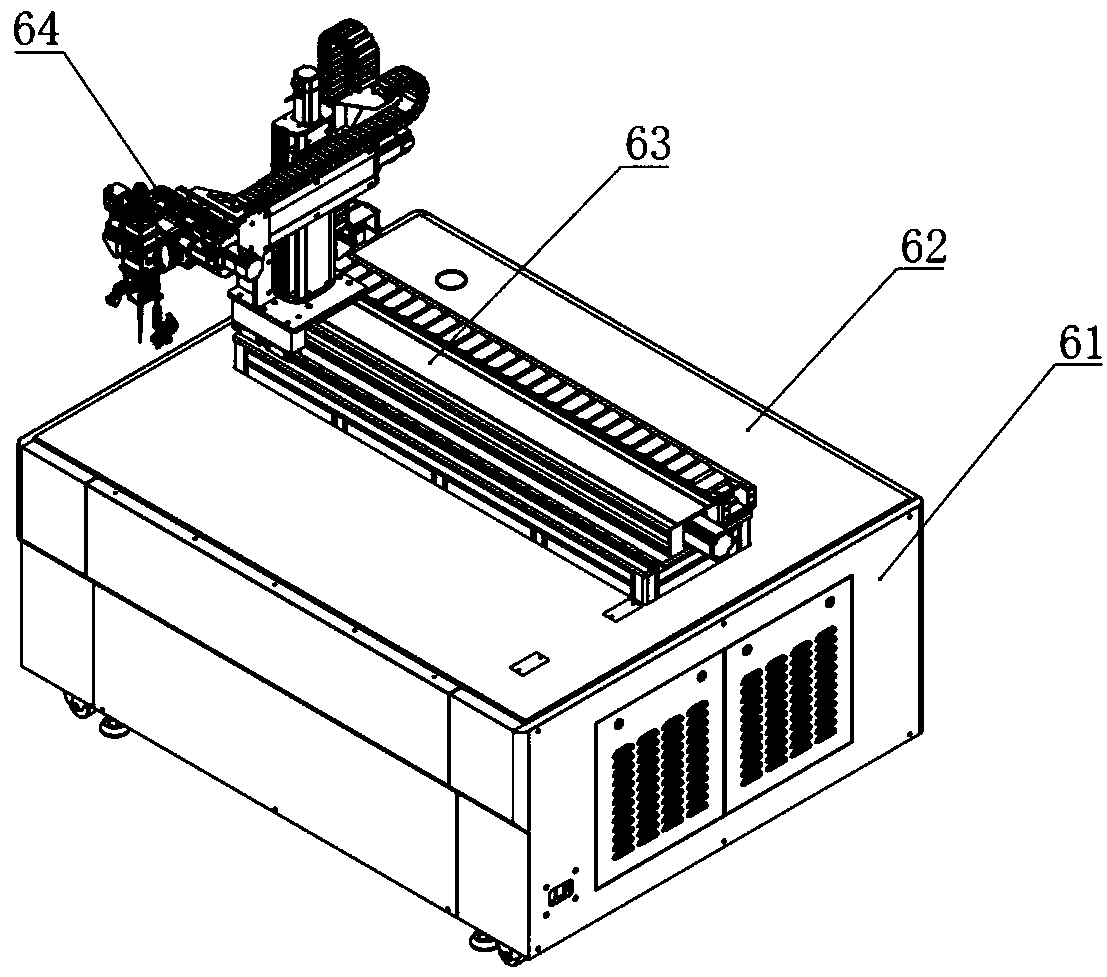

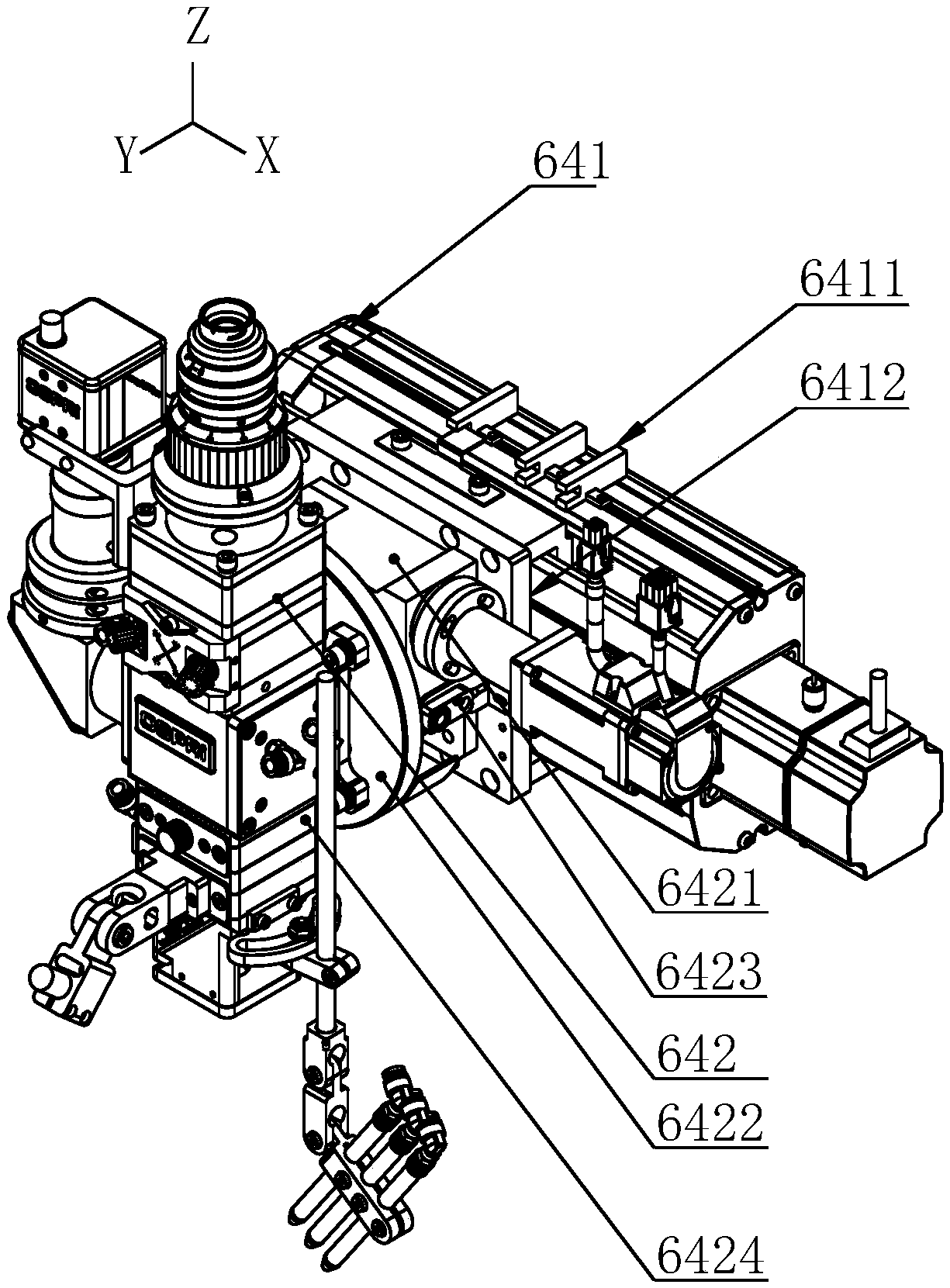

[0048] see figure 1 As shown, the laser swing welding system in the embodiment of the present invention includes a laser swing welding operation table 6, see figure 2 As shown, the laser swing welding operation table 6 includes a three-way moving mechanism 63 and a welding head swing mechanism 64, see figure 2 and image 3 As shown, the welding head swing mechanism 64 includes an X-axis moving mechanism 641 fixed on the three-way moving mechanism 63, a welding head tilting mechanism 642 fixed on the X-axis moving mechanism 641, and a welding head tilting mechanism 642 fixed on the welding head tilting mechanism 642. The laser welding head 6424, the system also includes a laser for providing a light source for the laser welding head 6424 (the laser can be purchased additionally when it is an actual application);

[0049] The three-way movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com