A modular agv

A modular and component technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of low degree of modularization, inconvenient installation and maintenance, etc., and achieve the effect of saving internal structure, convenient maintenance and solving the problem of large internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

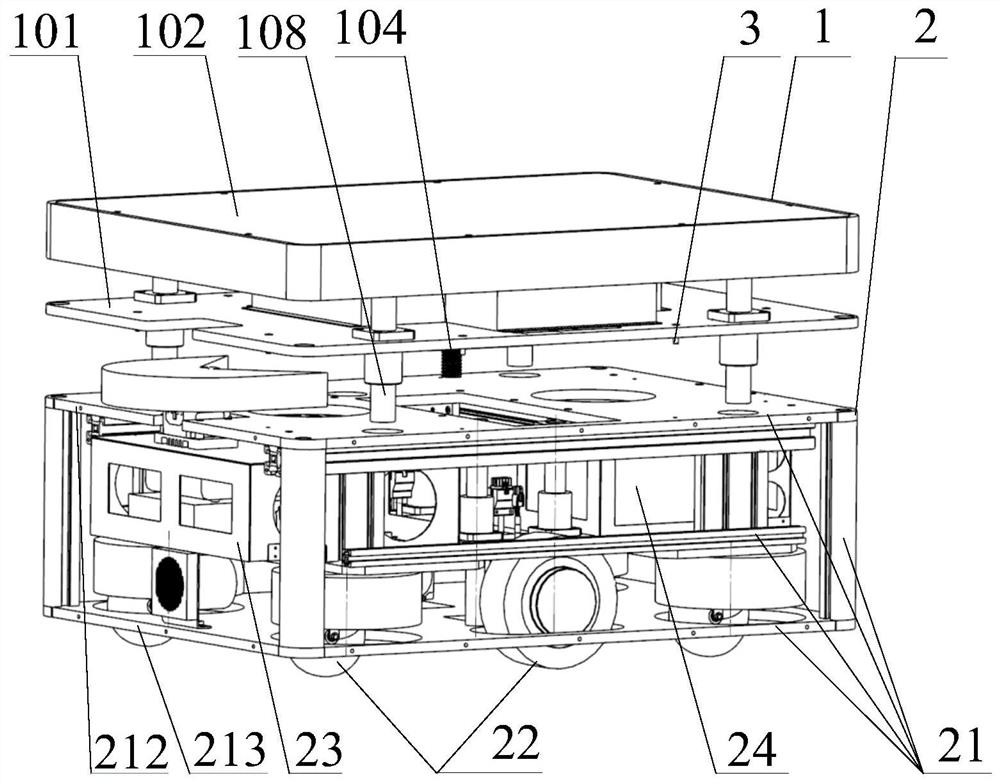

Embodiment 1

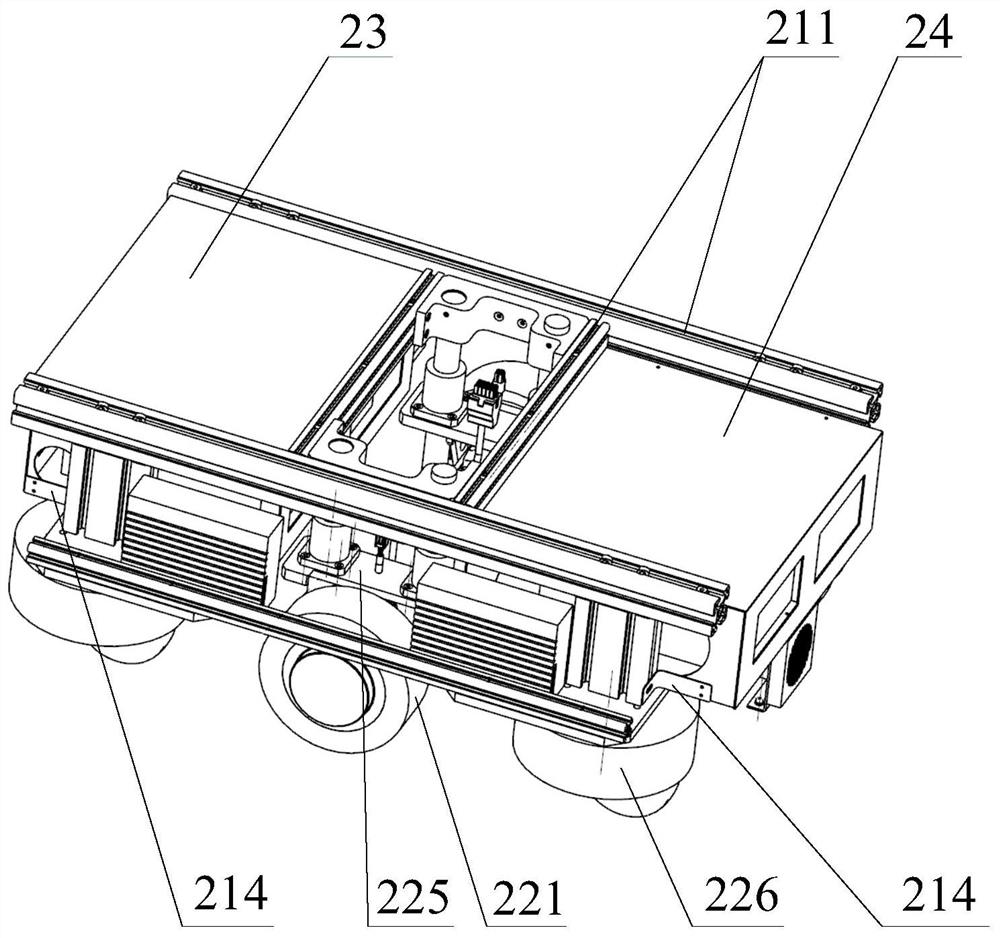

[0042] This embodiment provides a modular AGV, including a jacking mechanism 1 and a bottom mechanism 2. The jacking mechanism 1 mainly completes the lifting movement of the AGV, and the bottom mechanism 2 mainly completes the walking function of the AGV. The bottom mechanism 2 includes a skeleton component 21, the top of the skeleton component 21 is detachably connected to the jacking mechanism 1, the AGV functional structure is modularized, and the interchangeability of the same type of AGV mechanism can be realized, which is convenient for the overall maintenance of the AGV; the bottom of the skeleton component 21 is equipped with Walking assembly 22; the inside of the skeleton assembly 21 is detachably provided with an electrical component box 23 and a battery box 24, the electrical components box 23 is equipped with components for controlling the action of the jacking mechanism 1 and the walking assembly 22, and the battery box 24 is installed in a useful It is used for th...

Embodiment 2

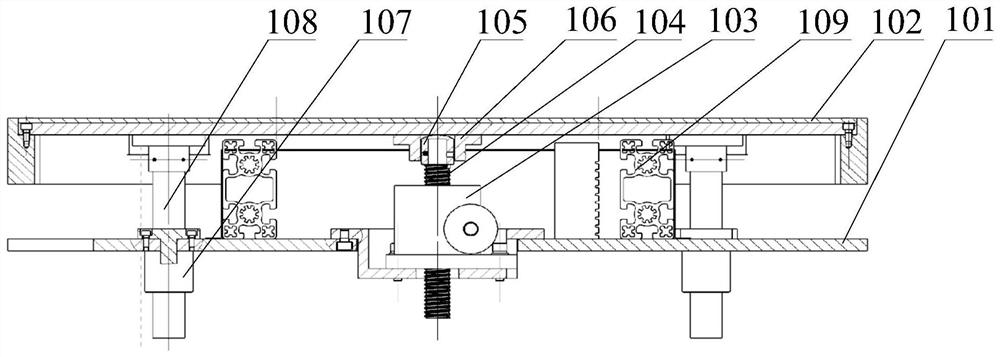

[0044] Further improvement on the basis of Embodiment 1, the jacking mechanism 1 includes a jacking support plate 101 of a cuboid structure, a load plate 102 of a cuboid structure, a nut pair 103 and a screw mandrel 104; the jacking support plate 101 is connected with the screw 3 The skeleton assembly 21 is connected; the geometric center of the lifting support plate 101 is provided with a nut pair 103 and a driver for driving the nut pair 103 to rotate through screws; The axial direction of 103 moves linearly up and down, and the axial top end of the screw rod 104 is connected with the bearing plate 102 .

Embodiment 3

[0046] Further improvement on the basis of Embodiment 2, the axial top end of the screw rod 104 is provided with a spherical flange head 105, and the spherical flange head 105 includes a long axis rod section and a head provided at one end of the rod section. The mounting hole used for the transition fit of the end of the screw rod 104 to penetrate into the connection, the top surface of the head of the spherical flange head 105 is an arc-shaped convex surface, and the lower plate surface of the bearing plate 102 is fixed with a card seat 106 by bolts; the spherical flange The head 105 extends into the deck 106, and the outer wall around the spherical flange head 105 fits in clearance with the inner wall of the deck 106. The top surface of the spherical flange head 105 is in point contact with the lower surface of the bearing plate 102. The spherical flange head 105 is near the edge and is provided with two symmetrical cut surfaces along the direction perpendicular to the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com