Bagged steel ball unloading device

A steel ball and steel pipe technology, applied in the field of bagged steel ball unloading device, can solve problems such as big hidden dangers, inability to solve safety technical problems, and injury to operators, and achieve a safe, simple structure and easy to replace. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

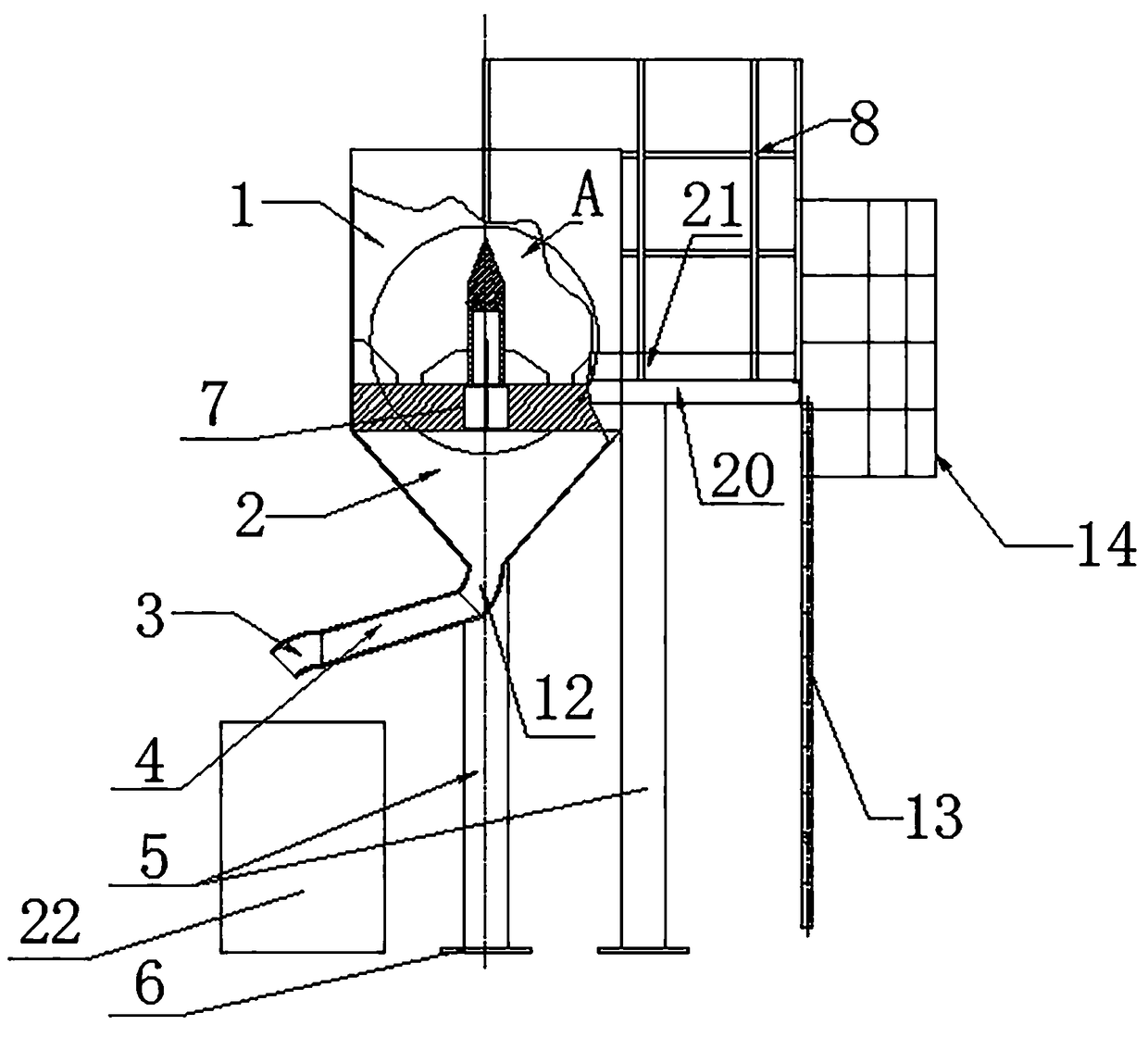

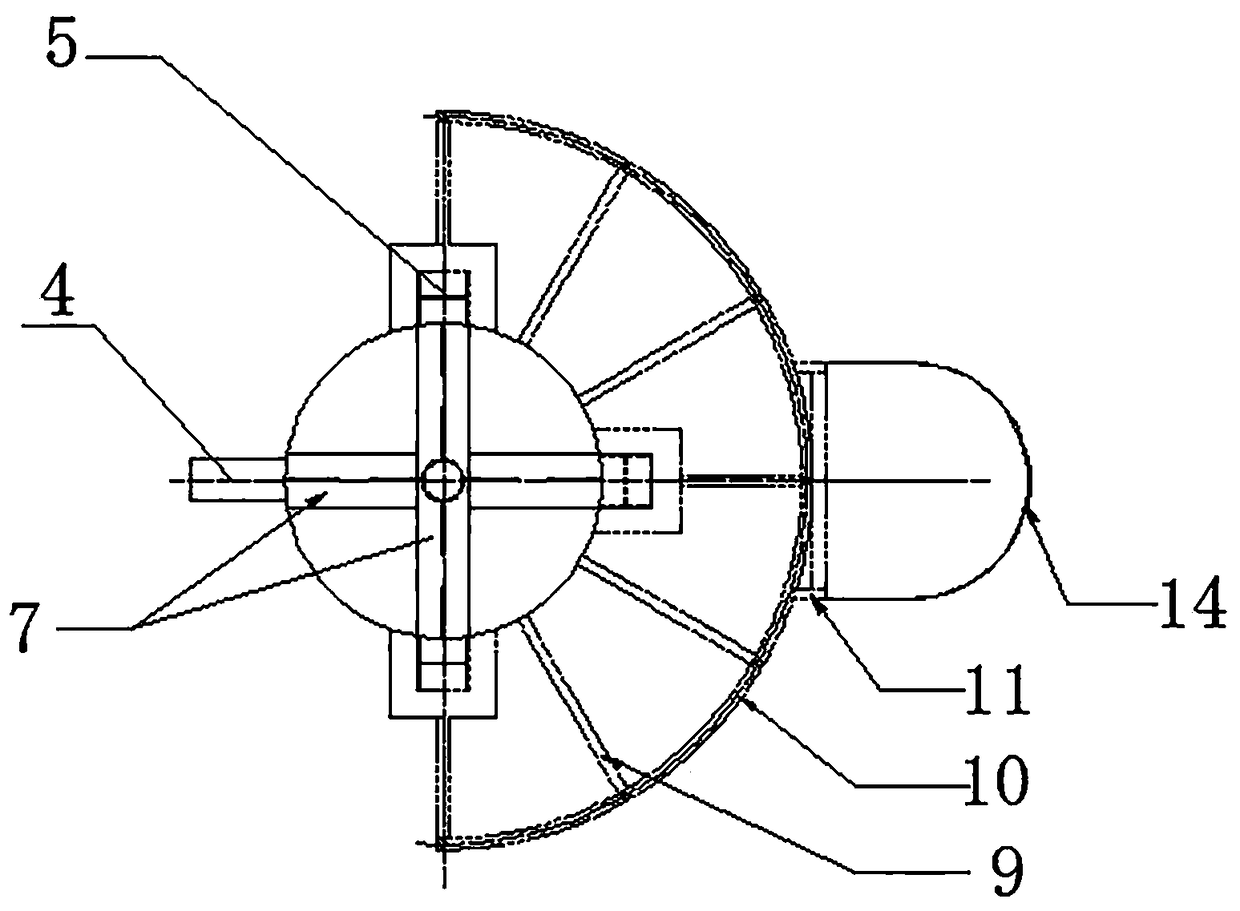

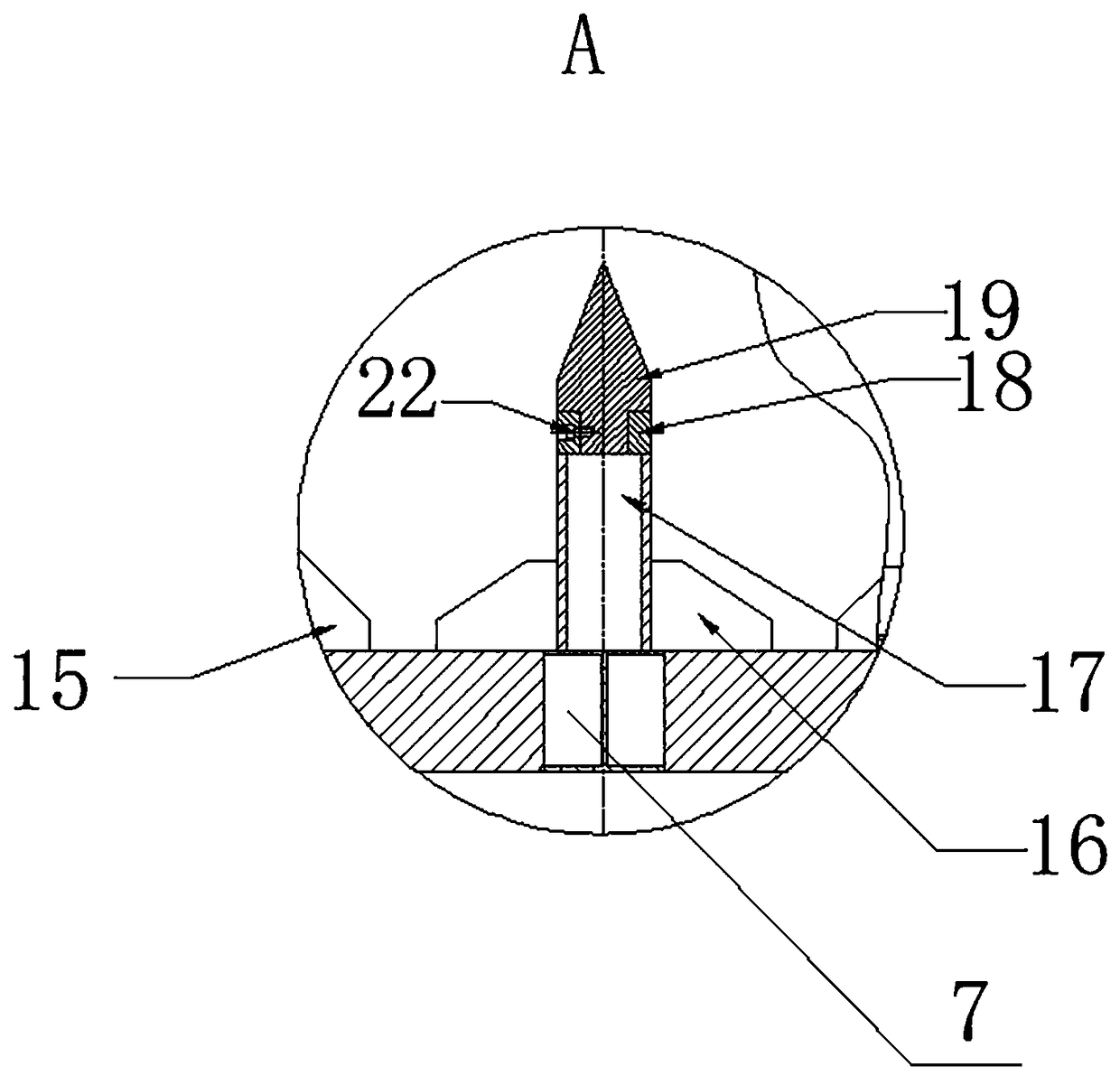

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] Such as Figure 1-3 As shown, a bagged steel ball unloading device includes a support 5, a support platform 20 is provided on one side of the top of the support 5, a steel ball bucket column 1 is fixed on the other side of the top of the support 5, and the support 5 includes a vertical Three supporting legs are welded on the lower part of the outer wall of the steel ball bucket cylinder 1, and the three supporting legs form a right triangle, and the bottom of each supporting leg is welded with a supporting leg seat 6. The lower part of the outer wall of the steel ball bucket cylinder 1 is welded with a semicircular operating support beam 9, the outer circle of the operating supporting beam 9 is welded with a semicircular platform beam 10, and the tops of the operating supporting beam 9 and the semicircular platform beam 10 are welded wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com