Device and method for measuring breakage rate of inner wall coating of pipeline

A technology for measuring pipelines and breakage rates. It is used in measuring devices, material analysis by electromagnetic means, instruments, etc. It can solve problems such as repairing and inability to judge coatings, and achieve the effect of easy installation and long design life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

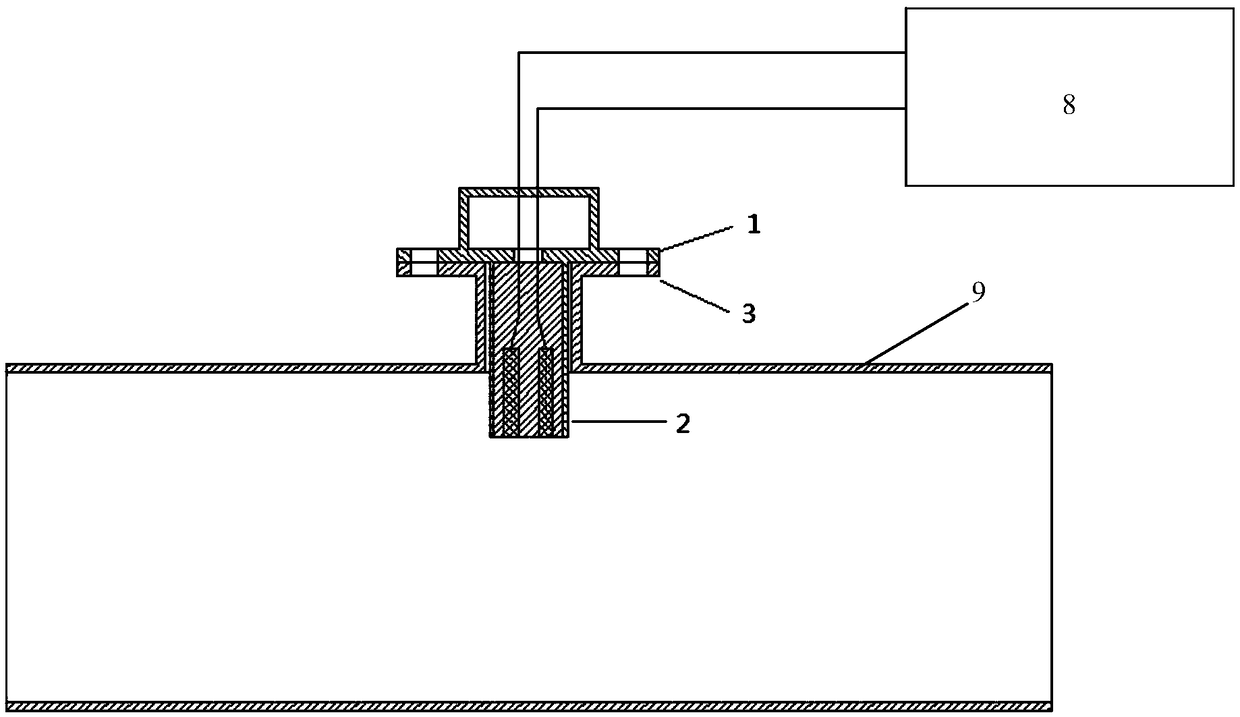

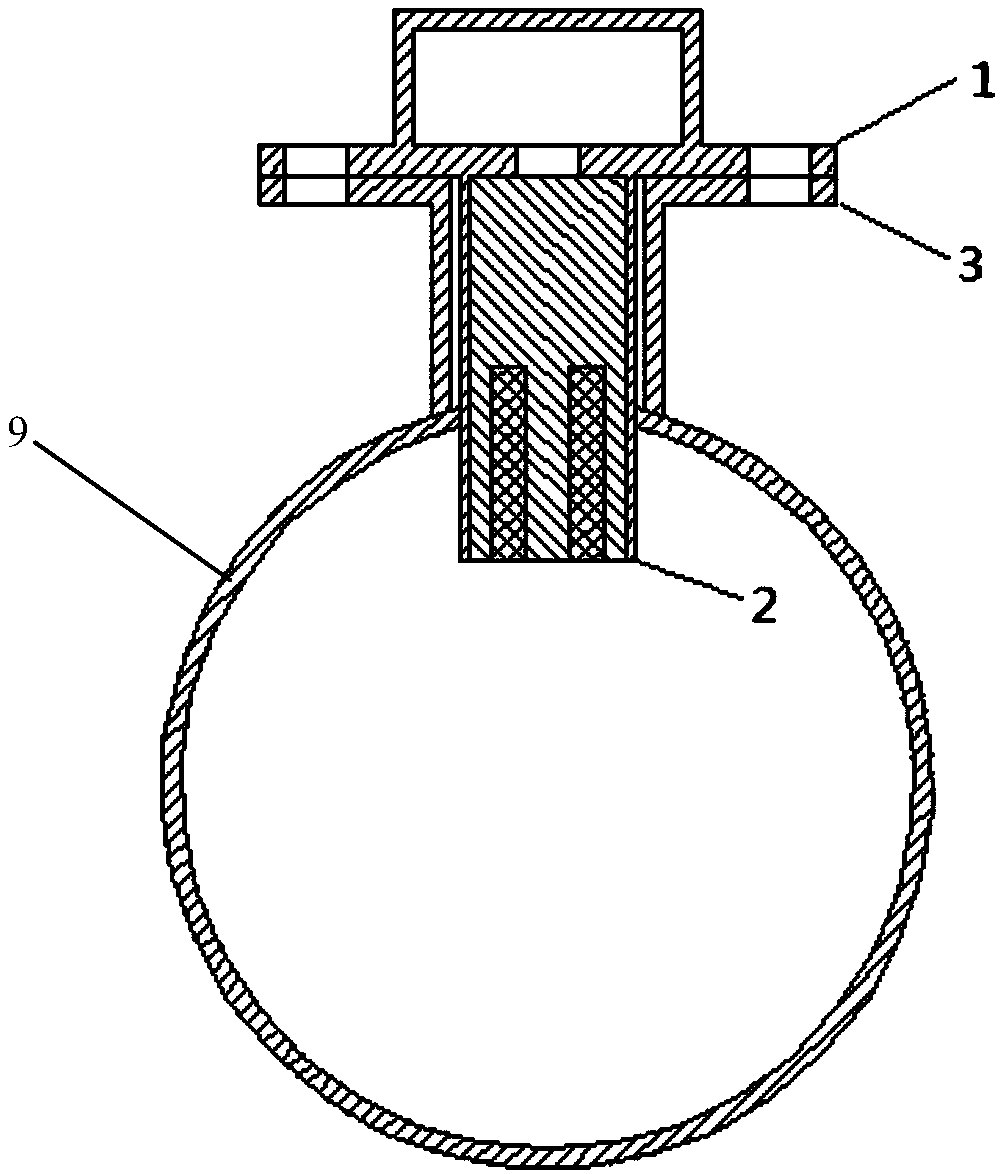

[0044] Such as figure 1 with figure 2 As shown, a device for measuring the damage rate of the coating on the inner wall of the pipeline, the device can monitor and measure the damage of the coating on the inner wall of the pipeline 9 that has been equipped with a cathodic protection anticorrosion system; the device includes a flange 1, an electrode probe 2. The flange base 3 and the potentiostat 8 welded on the pipeline.

[0045] The flange plate 1 is a steel flange, the surface is coated with anti-corrosion paint, the size of the flange depends on the diameter of the pipe, and the flange material can also be insulating materials such as glass fiber reinforced plastics, polyvinyl chloride, and polytetrafluoroethylene.

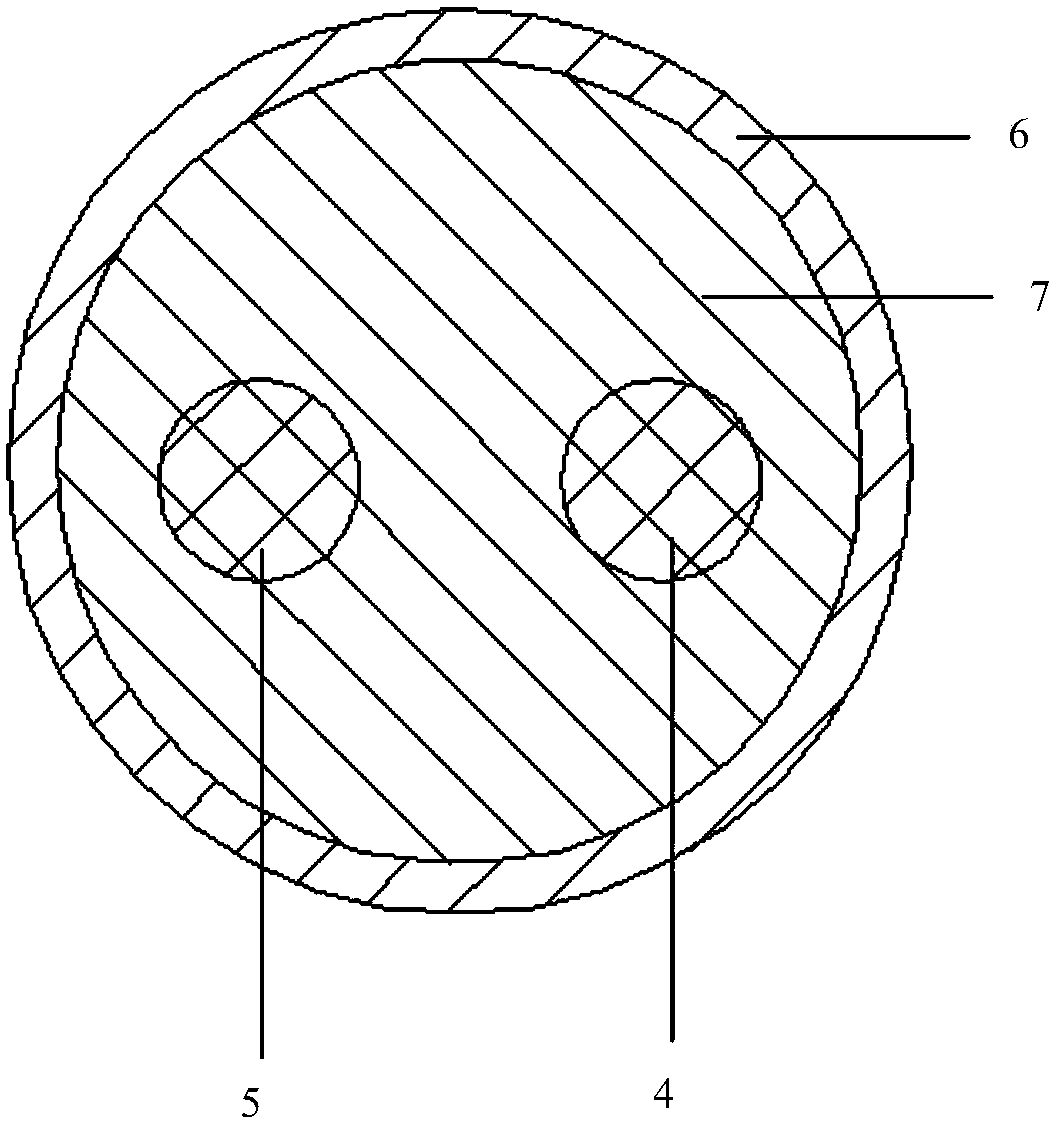

[0046] The electrode probe 2 is a bipolar probe, and the materials are respectively platinum and carbon steel; carbon steel is simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com