A loader work condition identification model construction and identification method thereof

A technology of working condition recognition and construction method, applied in character and pattern recognition, construction, computer parts and other directions, can solve the problem of low recognition accuracy, improve the accuracy and efficiency, improve the accuracy, and the preprocessing method is accurate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

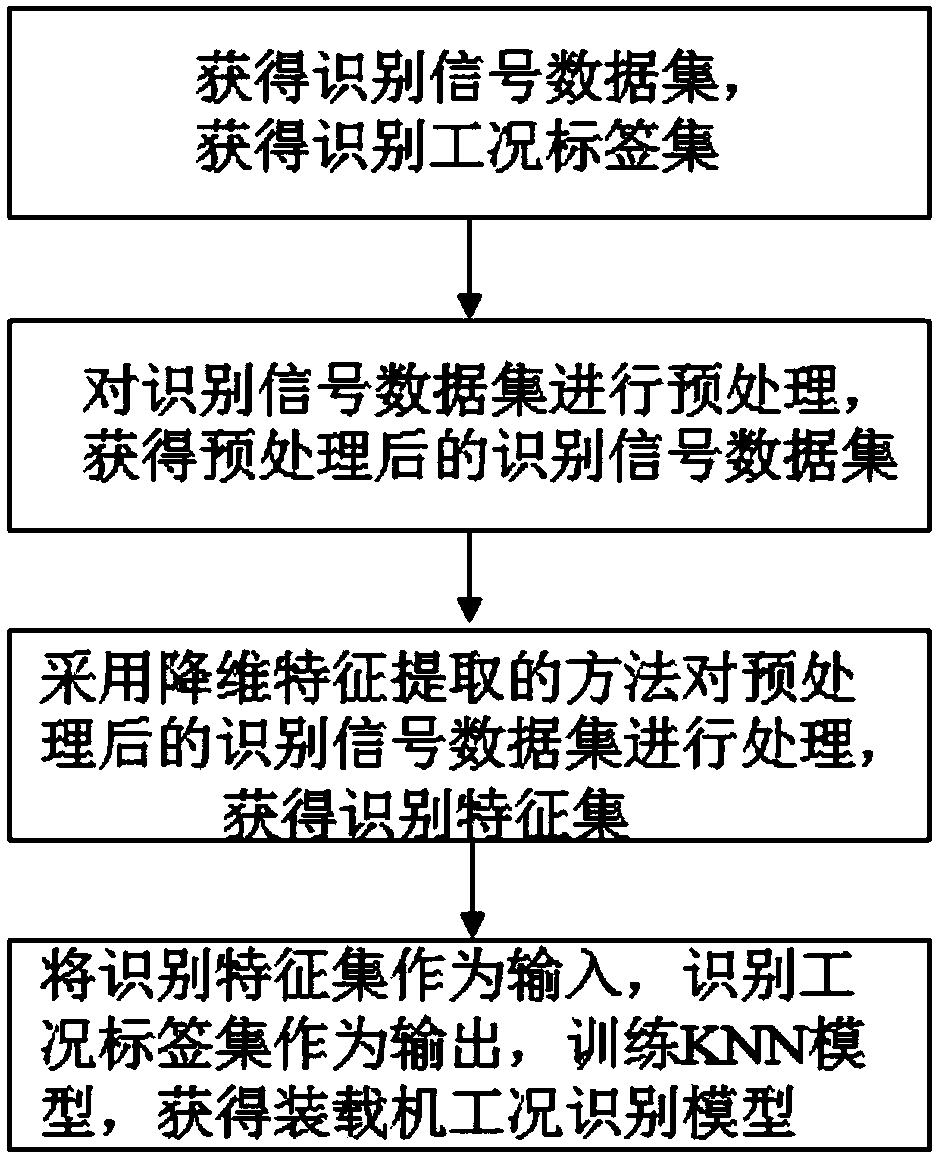

[0031] This embodiment discloses a method for constructing a loader working condition identification model. The method includes the following steps:

[0032] Step 1, collect multiple groups of identification signal data of the loader under different working conditions as the identification signal data set; each group of identification signal data in the identification signal data set corresponds to a working condition label, and obtain the identification working condition label set;

[0033] The working condition of the loader refers to the working condition of the loader under the conditions directly related to its action. Generally, the working condition of the loader includes shoveling, full-load transportation and unloading.

[0034] In this embodiment, the working conditions of the loader are carefully divided to ensure the accuracy of the judgment. The working conditions of the loader include forwarding with no load, digging, retreating with a full load, forwarding with a...

Embodiment 2

[0088] The invention also discloses a loader working condition identification method, the method comprising:

[0089] The working condition recognition model described in Embodiment 1 is used to recognize the signal data to be recognized of the loader that has been processed in Step 1 to Step 3 in Embodiment 1.

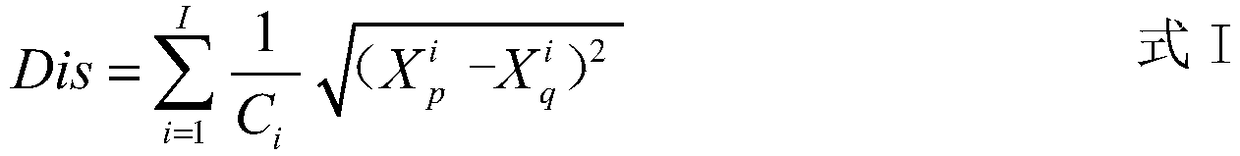

[0090]In this embodiment, the signal data to be identified is [loader front axle torque, loader front axle speed, loader rear axle torque, working pump pressure, steering pump pressure, engine speed]=[1450,1280,2870, 8.8, 16.9, 2430], after processing in steps 1-3 of Embodiment 1, the obtained recognition feature set is [front axle torque, rear axle torque, main pump power]=[0.451,0.942,0.287], using After the working condition identification model is identified, the identification result is 2-shoveling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com