A kind of preparation method of fuel element

A fuel element and fuel technology, applied in the field of molten salt reactors, can solve problems such as high cost of preparation methods, and achieve the effects of reducing preparation costs, improving utilization ratio, and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

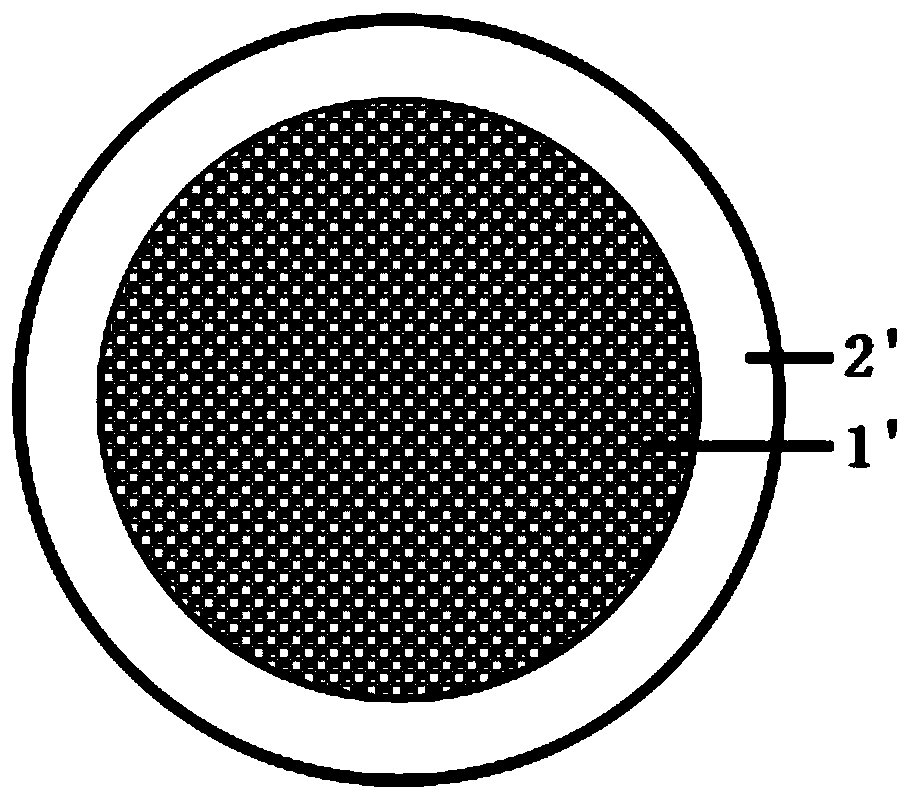

[0024] Embodiment 1 (spherical fuel element, no fuel shell is SiC ceramics)

[0025] Computer-aided software (such as Pro / Engineering, Unigraphics, CATIA, Solidworks, etc.) designs the 3D model of the fuel-free shell, then slices and layers (using Magics, Mimics, etc.), and imports the outline into the 3D printing device.

[0026]Prepare the following system: mix (mercaptopropyl)methylsiloxane (gel) and vinyltrimethoxysilane (gel) 1:1, add 0.4wt% UV radical initiator, 0.2wt% Radical scavengers act as inhibitors, 0.16 wt% of chemical UV absorbers to keep them active in relevant wavelengths of UV light. The addition of silane compounds generally reduces the oxygen content and pushes the ceramic composition from SiOC to SiC.

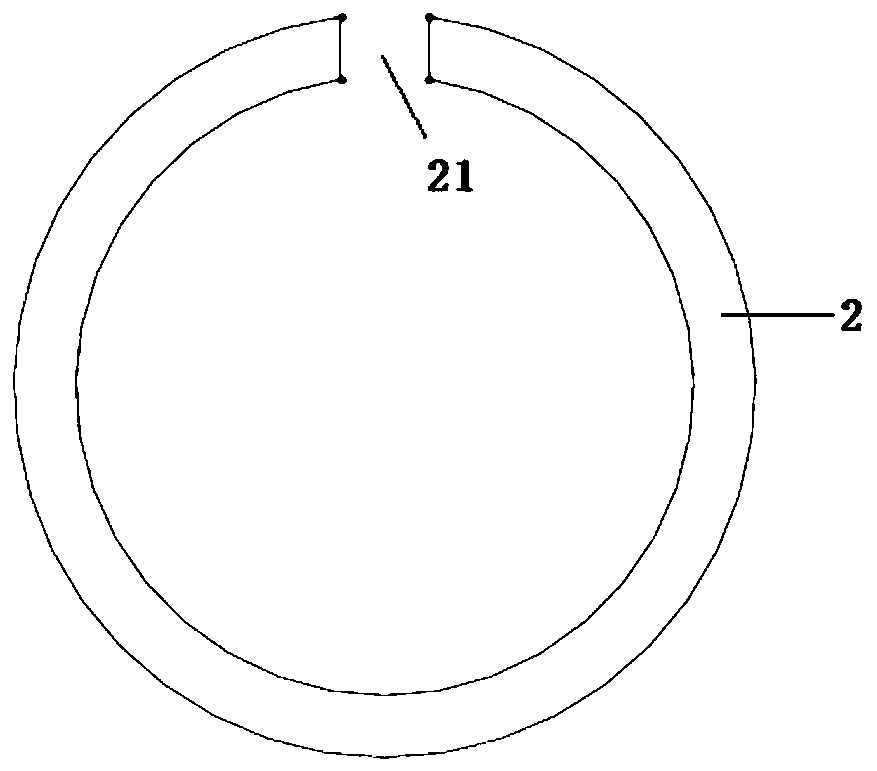

[0027] The above system uses SLA 3D printing equipment improved by self-propagating polymer waveguide technology to print the spherical shell 2, and the top of the spherical shell 2 has an opening 21, such as figure 2 , forming a preceramic polymer struc...

Embodiment 2

[0033] Embodiment 2 (spherical fuel element, no fuel shell is Hastelloy C-276 (00Cr16Mo16W4))

[0034] Computer-aided software (such as Pro / Engineering, Unigraphics, CATIA, Solidworks, etc.) designs the 3D model of the fuel-free shell, then slices and layers (using Magics, Mimics, etc.), and imports the outline into the 3D printing device.

[0035] Using the current mainstream powder making technology, such as the new generation plasma rotating electrode atomization powder making technology (N-PREP), the crucible-free electrode induction melting gas atomization powder making technology (EIGA), the plasma torch atomization powder making technology One is to prepare Hastelloy C-276 powder with an average particle size of about 50 microns.

[0036] The hastelloy C-276 powder is printed with SLM's 3D printing equipment to form a spherical shell with an opening at the top to form a fuel-free shell mold.

[0037] Use a mechanical mixer to uniformly mix graphite powder, binder pheno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com