Winding type lithium ion cell and preparation method thereof

A lithium-ion, winding technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of reducing production efficiency, production instability, complicated processes, etc., to improve production efficiency and production consistency, reduce The effect of defective rate, less short-circuit and poor size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

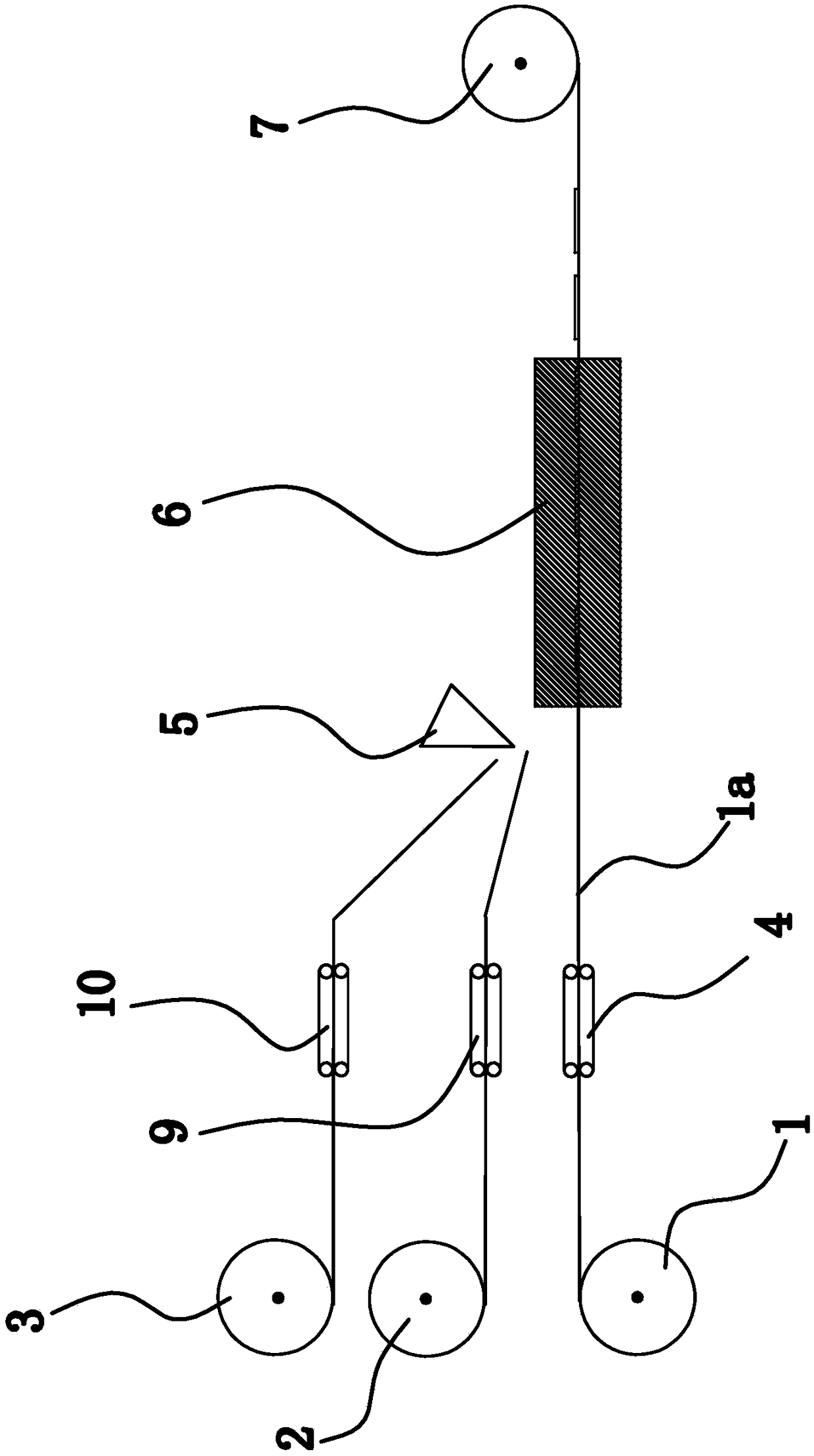

[0037] Such as figure 1 , 2 As shown in , 3, the preparation method of the winding type lithium ion battery comprises the following steps: select the diaphragm roll 1, and unwind the diaphragm roll 1 with the diaphragm belt 1a, so that the diaphragm belt 1a is driven by the transmission mechanism-4 to recombine Mechanism 6 transmits;

[0038] Select the positive electrode roll 2 and the negative electrode roll 3, respectively unwind the positive electrode roll 2 and the negative electrode roll 3 in the conveying direction of the diaphragm belt 1a, so that the positive electrode is conveyed to the shearing mechanism 5 under the drive of the conveying mechanism 29 , so that the negative electrode is conveyed to the shearing mechanism 5 under the drive of the conveying mechanism 3 10;

[0039] The positive electrode and the negative electrode are alternately cut into positive electrode single pieces 2a and negative electrode single pieces 3a by the cutting mechanism 5, and the ...

Embodiment 2

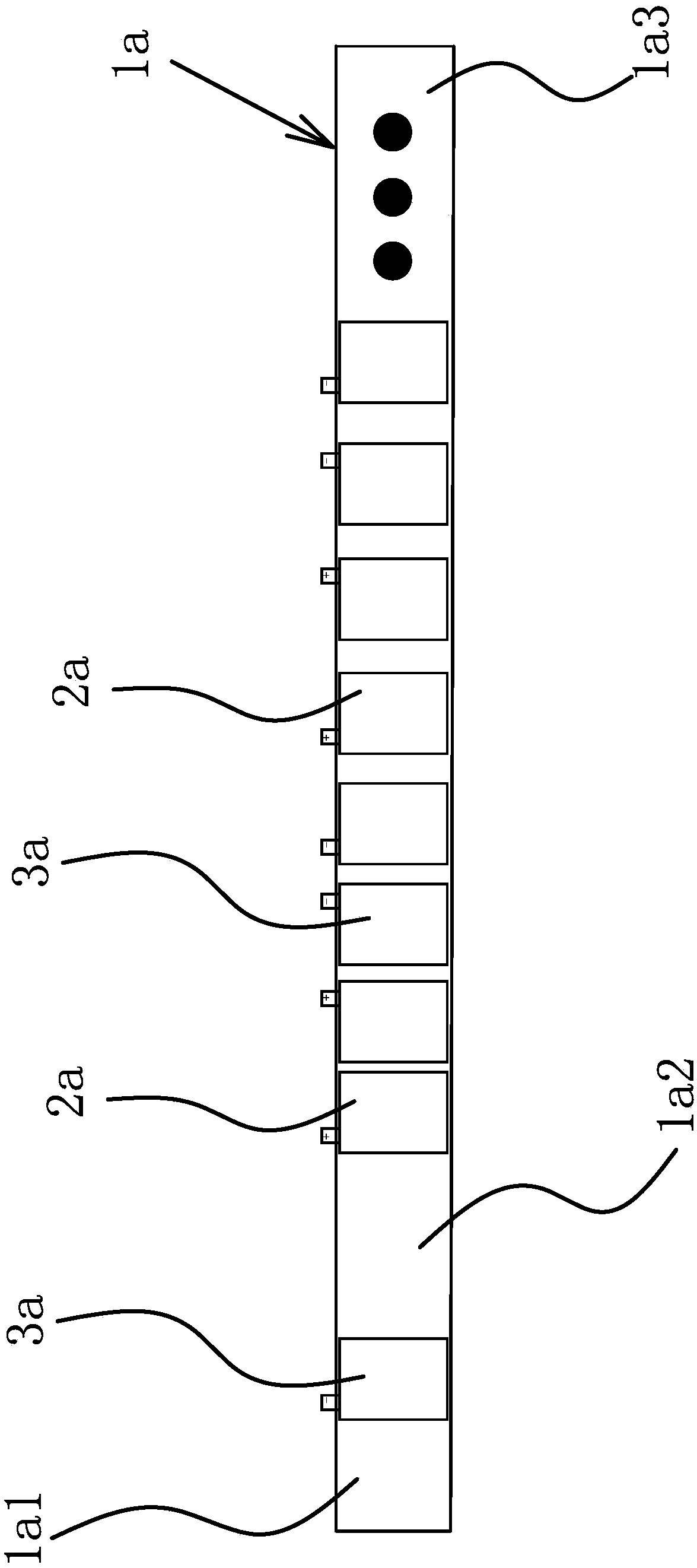

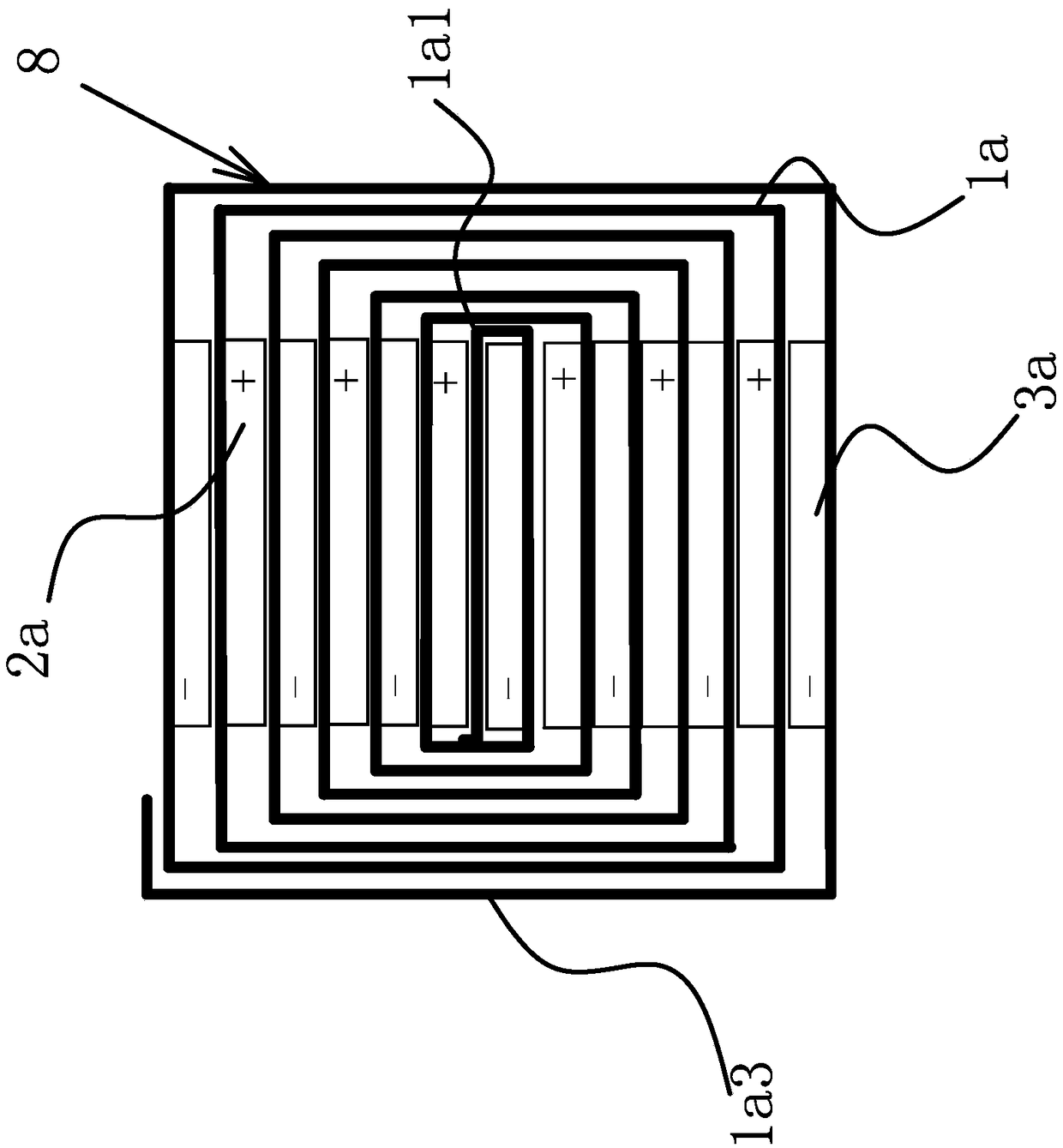

[0055] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that, as figure 2 , 4 As shown, there is a blank separator 1a2 with a second length value between the first positive electrode single sheet 2a and the first negative electrode single sheet, which is used to make the first positive electrode single sheet 2a and the first negative electrode single sheet when winding. There is a separator between the negative electrode single pieces 3a, and the tabs of the positive electrode single piece 2a and the negative electrode single piece 3a are staggered on both sides during winding. The blank separator 1a2 of the second length value can ensure that there is a separator between the first positive electrode single piece 2a and the first negative electrode single piece 3a when winding, and can also ensure that the tab phases of different polarities Staggered on both sides, there will be no short circuit caus...

Embodiment 3

[0057] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that, as shown in 2 and 5, the head end of the diaphragm belt 1a is left with a blank diaphragm of any length, preferably, A blank separator 1a1 with a first length value is used, and a blank separator 1a2 with a second length value is spaced between the first negative electrode single piece 3a and the first positive electrode single piece 2a. The distance between the positive electrode monolith 2a and the negative electrode monolith 3a after placing the first positive electrode monolith 2a and the first negative electrode monolith 3a is according to the thickness and width of the positive electrode monolith 2a in the winding process, The thickness and width of the negative electrode sheet 3a, the thickness of the separator, and the number of coils are gradually increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com