Method for reducing same plate difference of rolling temperature of ultra-long TMCP plate

A rolling temperature and ultra-long technology, applied in the field of iron and steel metallurgy, can solve the problems of difficult performance uniformity control, large temperature difference between the head, middle and tail of the steel plate, and low rolling production efficiency, so as to achieve uniform structure and high production efficiency , The effect of process cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A method for reducing the difference between the rolling temperature of the super-long TMCP plate and the same plate. The process route of the method for reducing the difference between the rolling temperature of the super-long TMCP plate is: hot metal KR pre-desulfurization, converter smelting, LF refining, soft stirring, plate Continuous casting of slabs, reheating of slabs, rough rolling, cooling of intermediate slabs, finishing rolling, water cooling of steel plates, thermal straightening of steel plates, cooling of off-line stacks, cooling of stacks to 80°C on cooling beds, ultrasonic flaw detection of steel plates, shearing Cut and store.

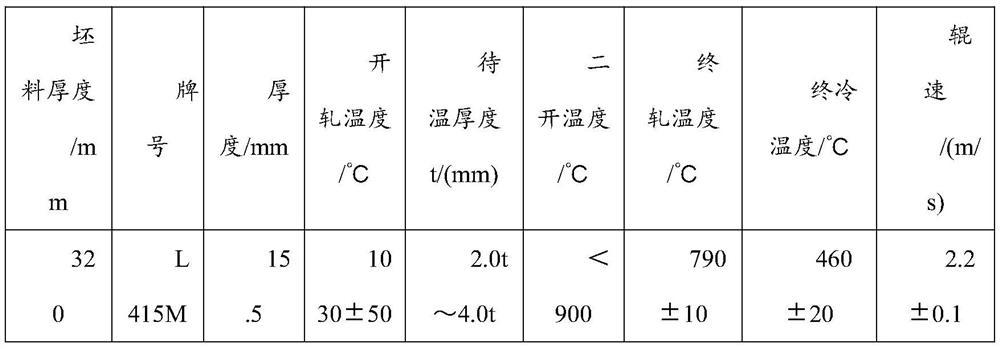

[0029] The control parameters of the mother plate rolling process are shown in Table 1.

[0030] The final rolling and final cooling temperatures are shown in Table 2.

example 1

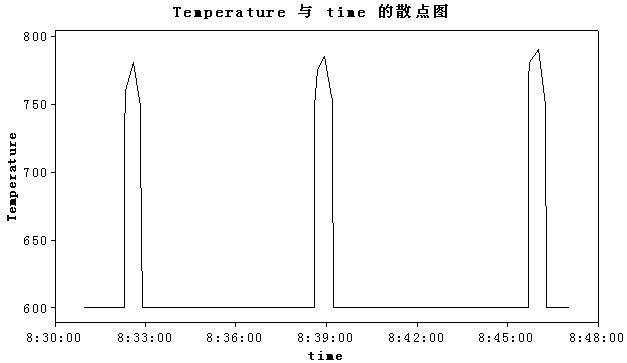

[0031] Example 1, the finish rolling pass is 7 passes, the thickness to be warmed is 40mm, and the temperature change curve of the finish rolling process is as follows figure 1 .

example 2

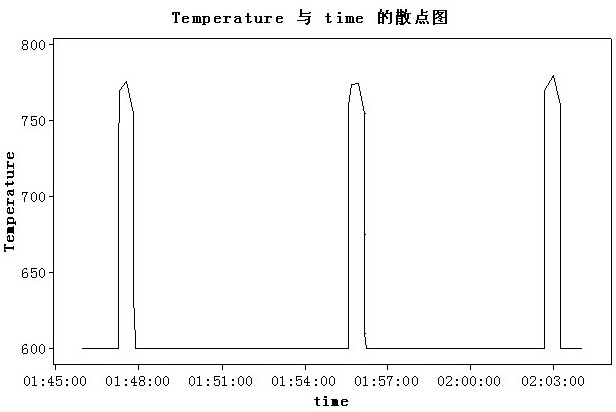

[0032] Example 2, the finish rolling pass is 5 passes, the thickness to be warmed is 35mm, and the temperature change curve of the finish rolling process is as follows figure 2 .

[0033] Table 1: Process Control Parameters of Mother Plate Rolling Process

[0034]

[0035] Table 2: Example final rolling and final cooling temperature

[0036]

[0037]

[0038] combine figure 1 with figure 2 Comparative analysis shows that the temperature drop of the three slabs in Example 2 is slow during the rolling process, the temperature difference between the head and the tail is small, and the temperature distribution is more uniform. From Table 2, the final rolling temperatures are 784, 780 and 784 ° C, respectively. Through the above comparative analysis, it can be seen that reducing the thickness of the intermediate billet to be heated and reducing the number of finishing rolling passes can not only reduce the rolling time, but also effectively reduce the difference in te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com