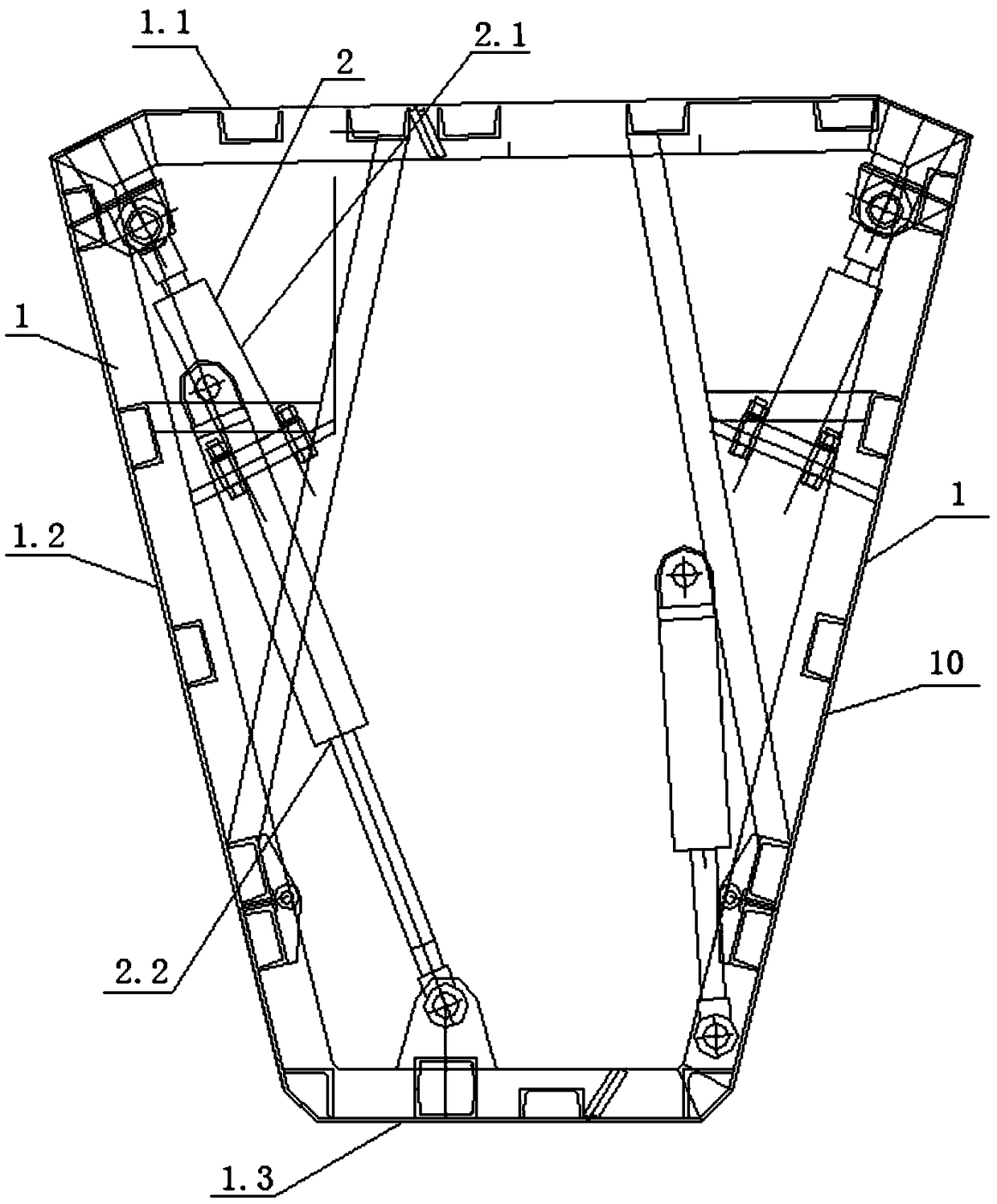

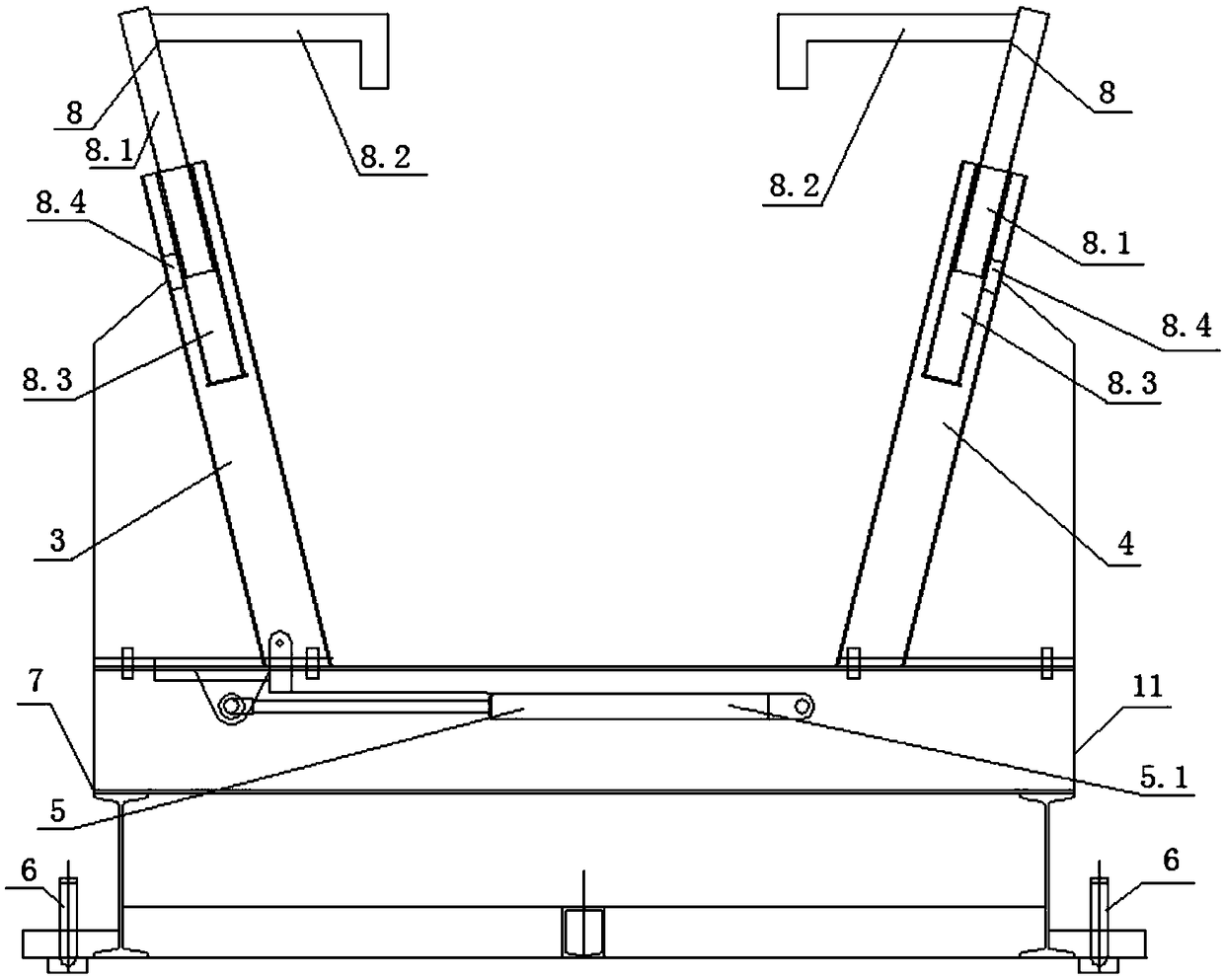

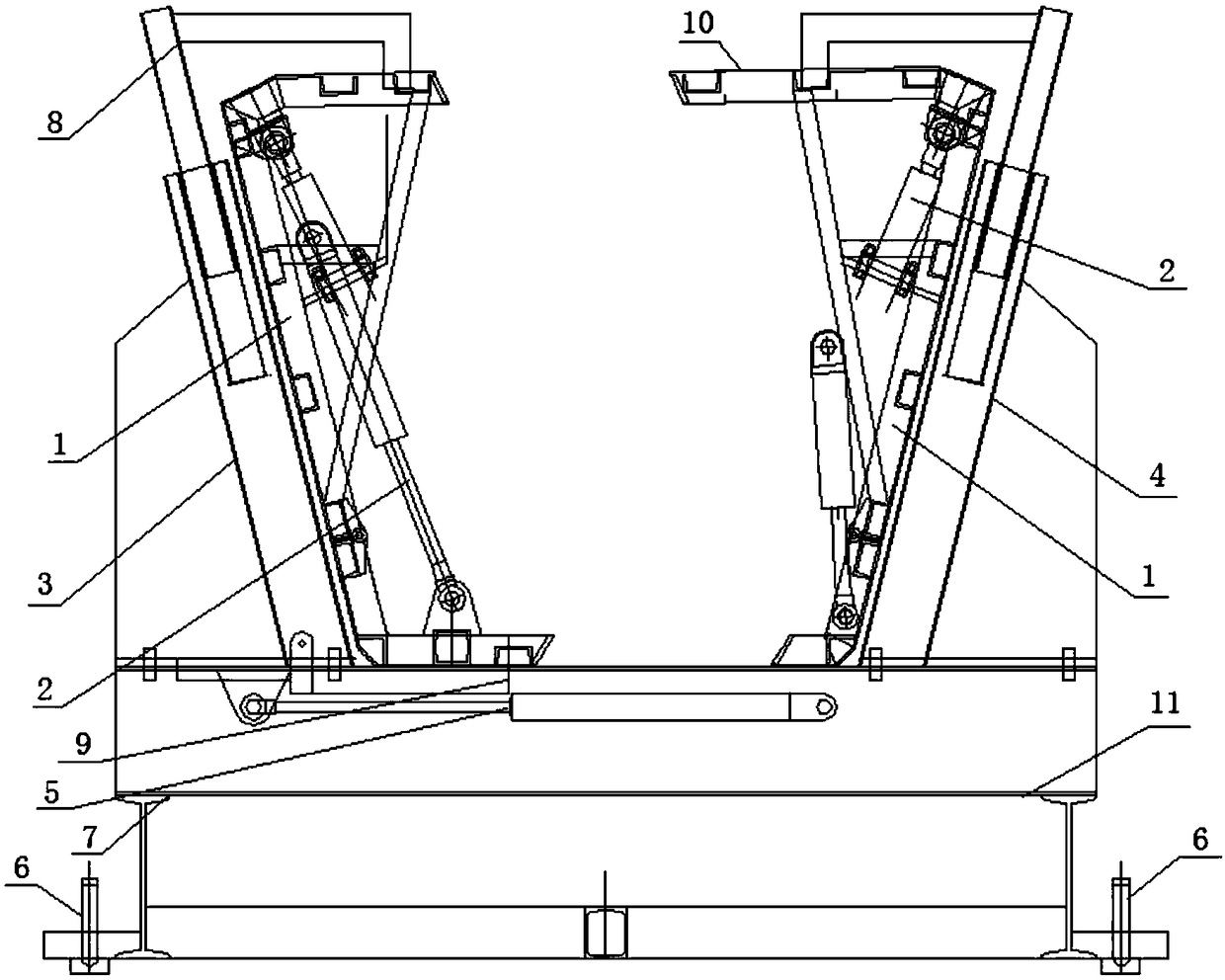

Trolley for dismounting and mounting integral contraction type hydraulic inner mold of prefabricated box girder and dismounting and mounting method of trolley

A method of disassembly and shrinkage, which is applied in the direction of ceramic molding cores, ceramic molding mandrels, etc., can solve the problems of general splicing accuracy of templates and pedestals, great influence of template deformation, difficulty in dismantling and construction of internal molds, etc., to achieve Reduce labor input, solve installation and adjustment difficulties, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] Now apply the present invention to a road bridge in a certain place as an embodiment, and apply the present invention to a 40m box girder in this road bridge as an example, including the following:

[0070] The main structural parameters of the 40m box girder of a highway bridge in a certain place are as follows: the beam height is 2m, the thickness of the top plate of the standard section is 19cm, the thickness of the web plate is 20cm, and the thickness of the bottom plate is 18cm; ; The roof of the center girder is 30cm thicker at the anchorage position of the negative bending moment prestressed steel beam to meet the needs of using round anchors for prestress; 2.5cm, the inner net protective layer is 2cm.

[0071] Prestressed concrete small box girders are widely used in expressways; prestressed concrete small box girders with a span of 30m are common. In recent years, with the development of social economy and the progress of bridge construction technology, prestre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com