Winding locating tooling of preimpregnated glass rove tape

A technology for positioning tooling and glass, which is applied to other household appliances, household appliances, household components, etc., and can solve the problem of uncontrollable and guaranteed winding tension uniformity and winding direction. Equalize the problem to achieve the effect of saving manpower and winding time, uniform width and good thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

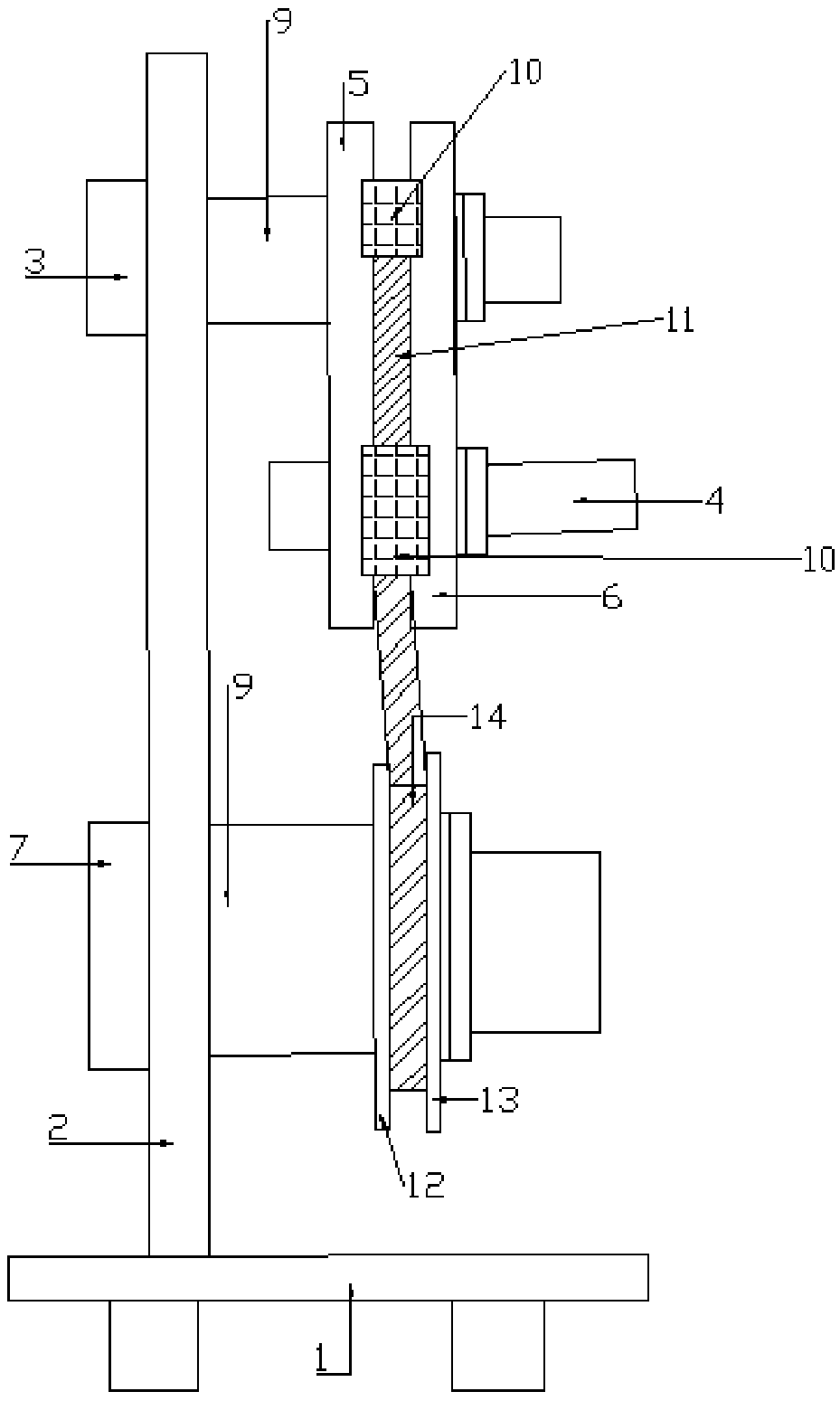

[0012] Referring to the accompanying drawings, the winding positioning tool for the prepreg glass roving tape of the present invention will be further described.

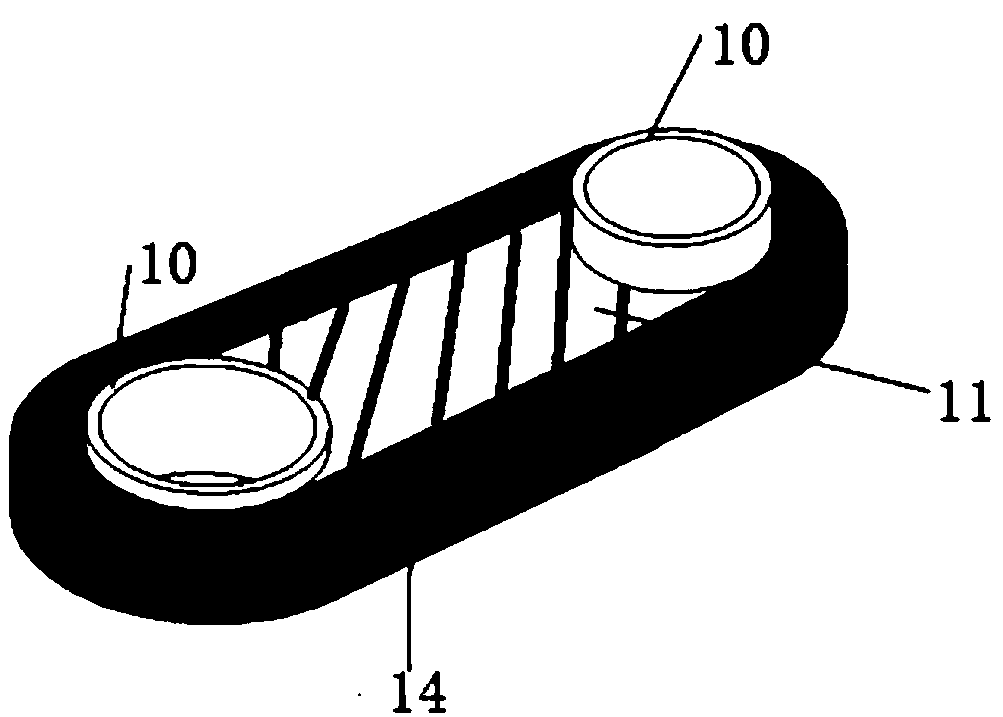

[0013] figure 1 It is a schematic plan view of the prepreg glass fiber roving tape winding body in the embodiment. like figure 1 As shown, the pre-impregnated glass fiber roving tape winding body (hereinafter referred to as part) in the embodiment includes two metal bushings 10, chopped fiber filler blocks 11 placed between the metal bushings 10, and the winding metal bushings 10 And the pre-impregnated glass roving tape 14 of the chopped fiber filler block 11.

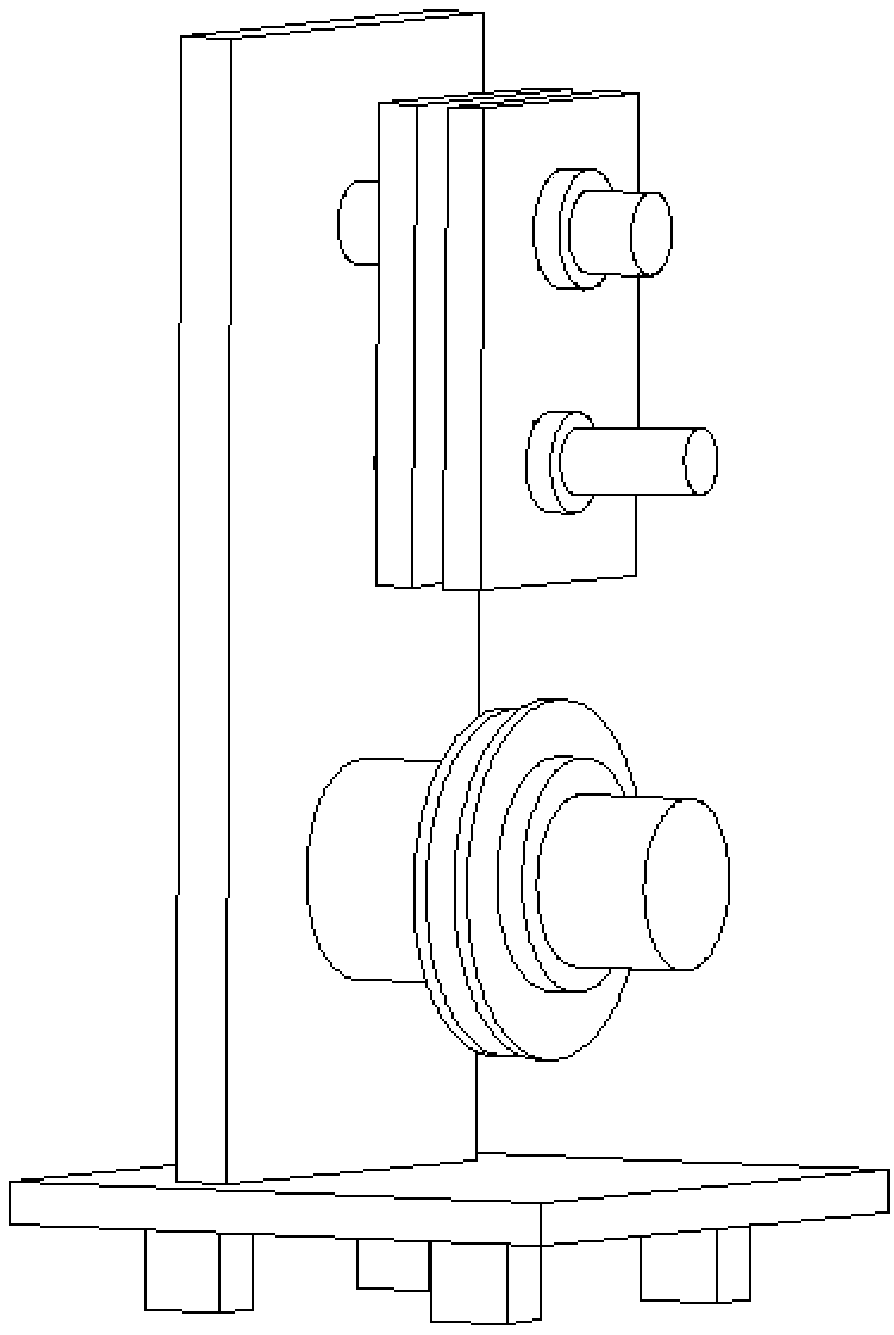

[0014] figure 2 It is a schematic structural view of the tooling of the present invention in the state of winding a prepreg glass roving tape, image 3 It is an axonometric view of the frock of the present invention. As shown in the figure, the winding and positioning tool of the prepreg glass roving tape of the present invention includes a base 1 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com