Fully-automatic integrated hybrid power assembly

A hybrid and fully automatic technology, applied in the direction of hybrid vehicles, power devices, pneumatic power devices, etc., can solve the problems of complex structure, high production and use costs, and the inability to fundamentally get rid of oil dependence and environmental protection, and achieve Effects of cost reduction, structure simplification, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, further illustrate the present invention.

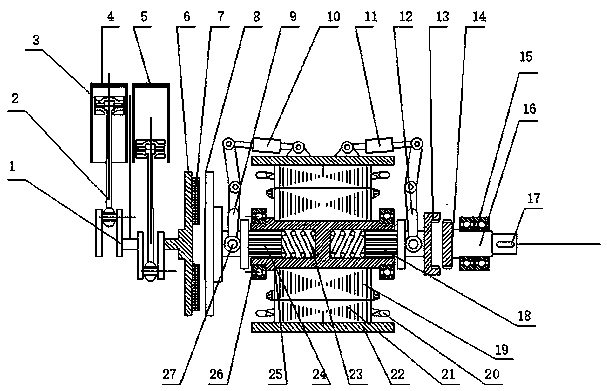

[0022] see figure 1 , a fully automatic integrated hybrid power assembly consisting of a cylinder, a piston 3, a crankshaft 1, a connecting rod 2, a flywheel 6, a driven disc 8 and a motor; the driven disc 8 is connected to the driven disc shaft 24 One end of the hollow motor shaft 25 is keyed, the other end of the hollow motor shaft 25 is keyed to one end of the sleeve shaft 18, the other end of the sleeve shaft 18 is connected to the sleeve 13, the sleeve 13 is matched with the main gear of the output shaft, and the output The main shaft gear is connected and fixed on the output main shaft 16; the motor housing 22 is provided with a driven disc electric push rod 10 and an engaging sleeve electric push rod 11, and the driven disc electric push rod 10 drives the driven disc shaft in the horizontal direction 24. The electric push rod 11 of the joint sleeve drives the joint sleeve shaft 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com