Electric logistics vehicle

A logistics vehicle and electric technology, which is applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of high center of gravity, large chassis space occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

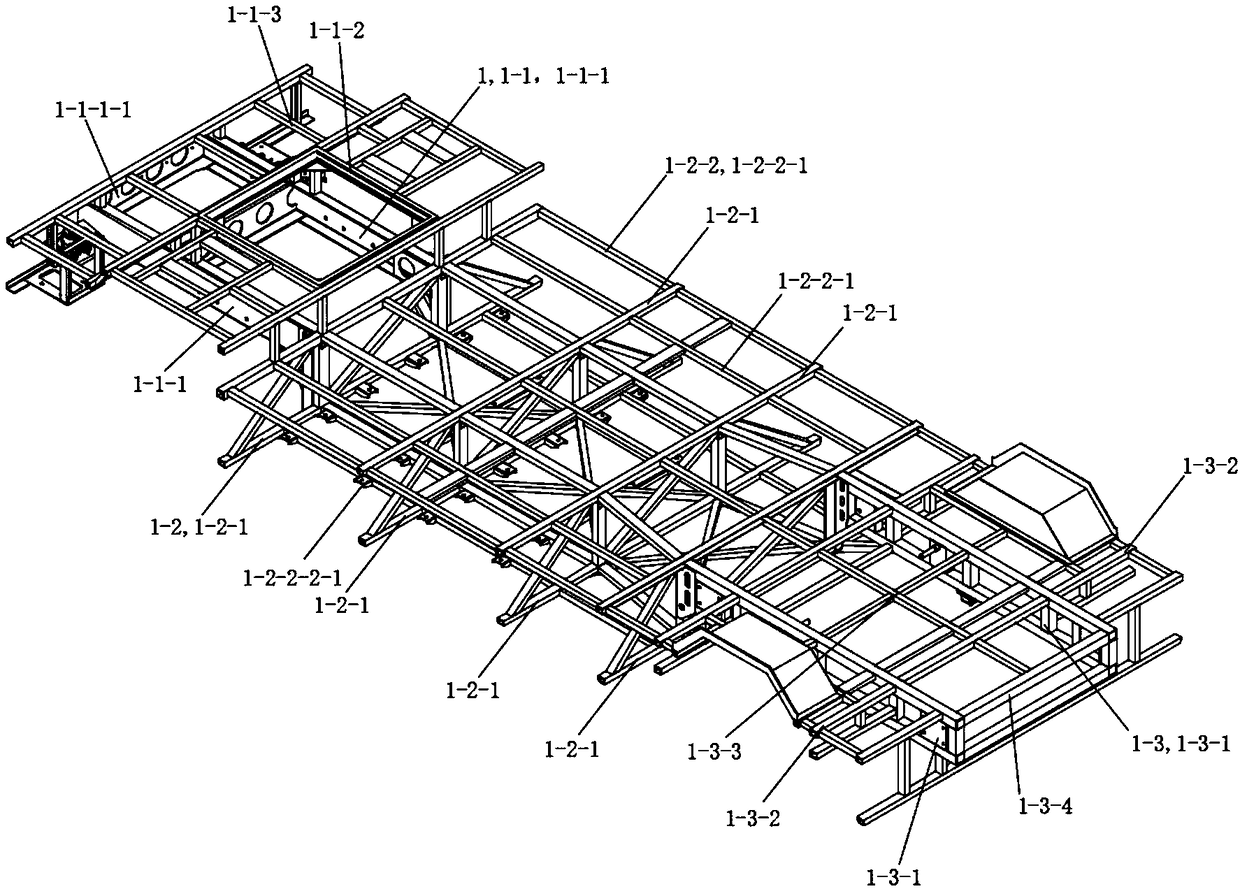

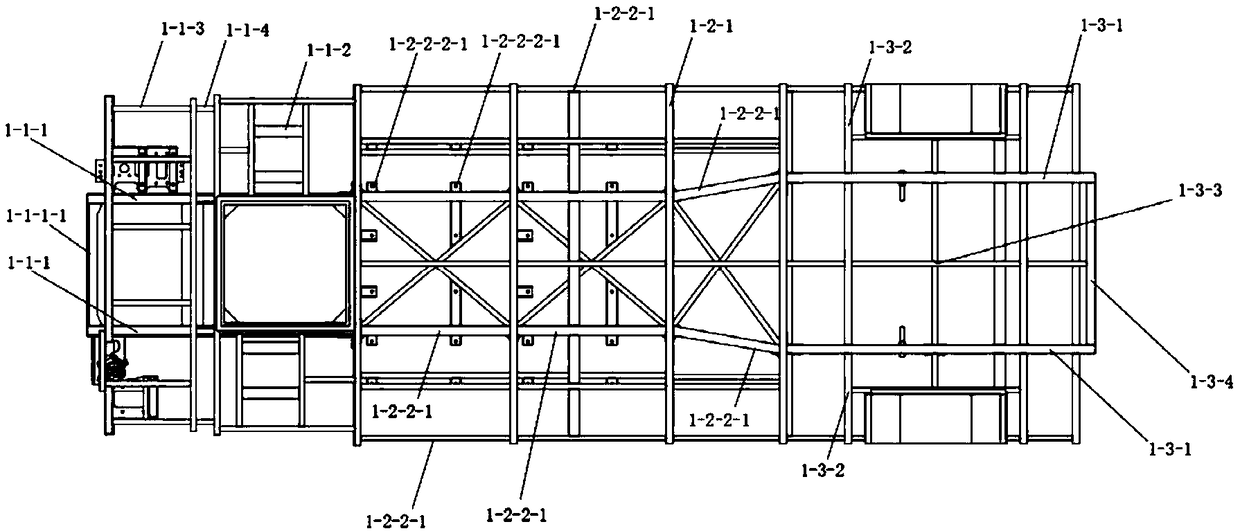

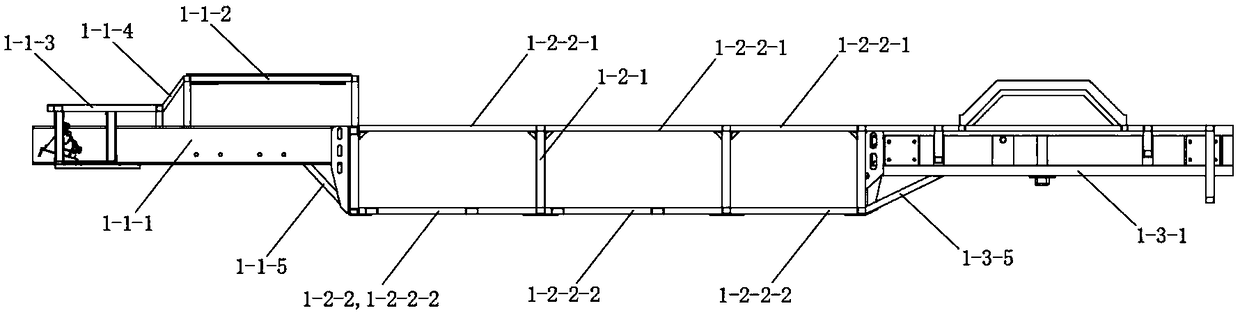

[0099] See Figure 1 to Figure 7 , The electric logistics vehicle of this embodiment includes a chassis 1, a power drive system 2, a subframe 3, a sunken rear axle 4 and a truck body 5. The chassis 1 includes a front bearing part 1-1, a middle bearing part 1-2 and a rear bearing part 1-3. The auxiliary frame 3 and the sunken rear axle 4 are installed on the front bearing part 1-1 and the rear bearing part 1-3 respectively. The power drive system 2 is arranged on the auxiliary frame 3 . The truck body 5 is installed on the chassis 1 .

[0100] The middle bearing part 1-2 of the chassis 1 includes a load-bearing frame 1-2-1 and a middle connecting rod assembly 1-2-2. There are multiple middle connecting rod assemblies 1-2-2, multiple load-bearing frames 1-2-1 are arranged side by side, and a middle connecting rod assembly 1 is passed between every two adjacent load-bearing frames 1-2-1 -2-2 connections. A storage space is formed between every two adjacent bearing frames 1-2...

Embodiment 2

[0139] This embodiment is basically the same as Embodiment 1, except that: the speed ratio of the first input gear set and the speed ratio of the second input gear set of the transmission mechanism 2 - 3 of the power drive system 2 are the same.

Embodiment 3

[0141] This embodiment is basically the same as Embodiment 1, the difference is:

[0142] See Figure 8and Figure 9 . It also includes a truck body 5 installed on the chassis 1 . The truck body 5 includes a compartment frame, a compartment panel 5-1, a compartment door 5-2 and a chassis compartment door 5-3. The compartment panel 5-1 is laid on the compartment frame. The compartment frame includes a front wall frame 5-4, a rear wall frame 5-5, a roof frame 5-6, a side wall frame 5-7 and a connector 5-8. Both ends of the roof frame 5-6 are connected to the front frame 5-4 and the rear frame 5-5. There are two side frame frames 5-7, and the two side frame frames 5-7 are fixed to both sides of the roof frame frame 5-6 by a plurality of connectors respectively. Edges at both ends of the side frame 5-7 are respectively connected to the front frame 5-4 and the rear frame 5-5. The compartment door 5-2 is located on the back wall frame 5-5. The chassis door 5-3 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com