Quick self-locking device and shaft system

A self-locking device and fast technology, applied in the field of mechanical transmission, can solve problems such as low efficiency, high assembly precision requirements, and low fault tolerance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

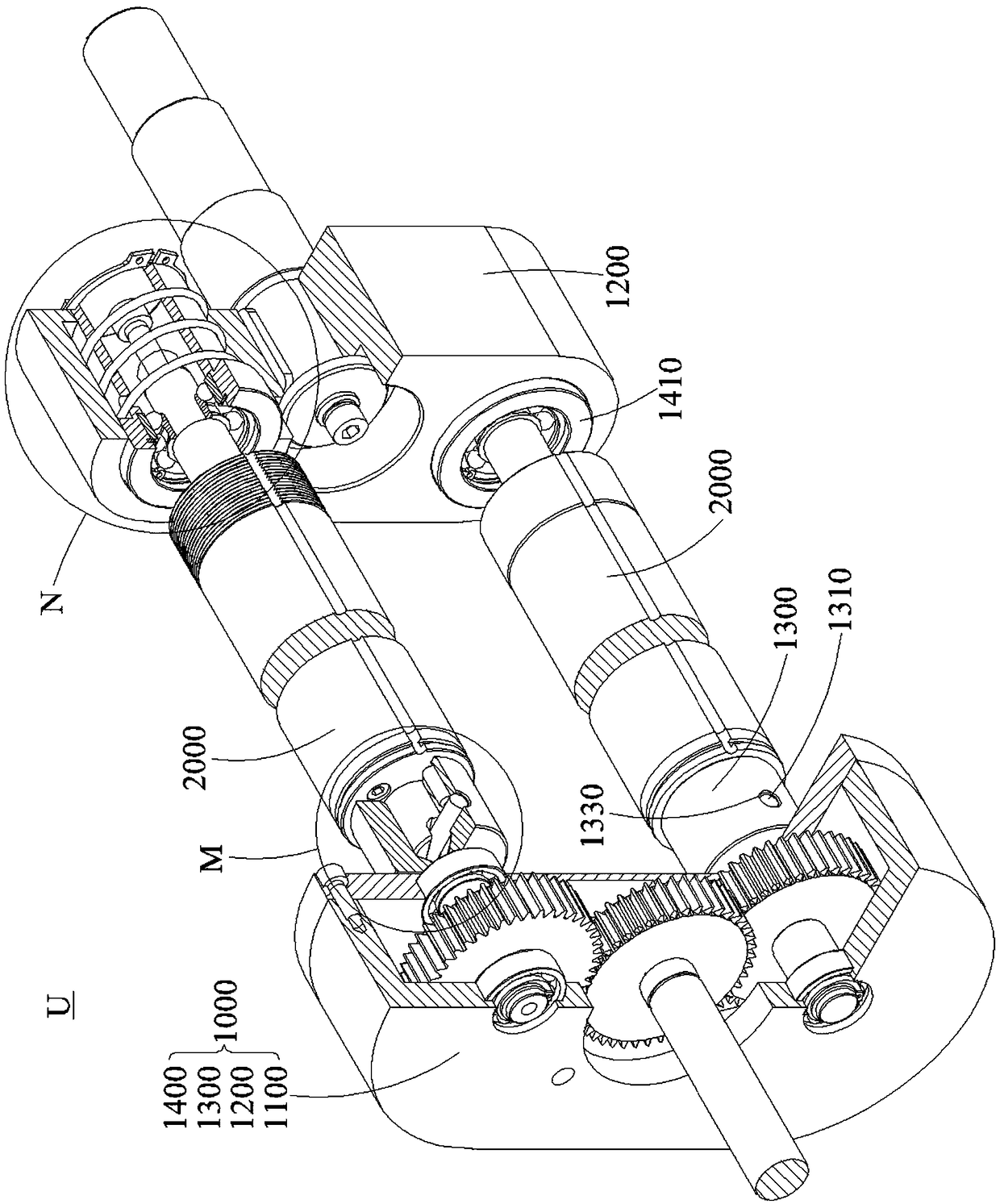

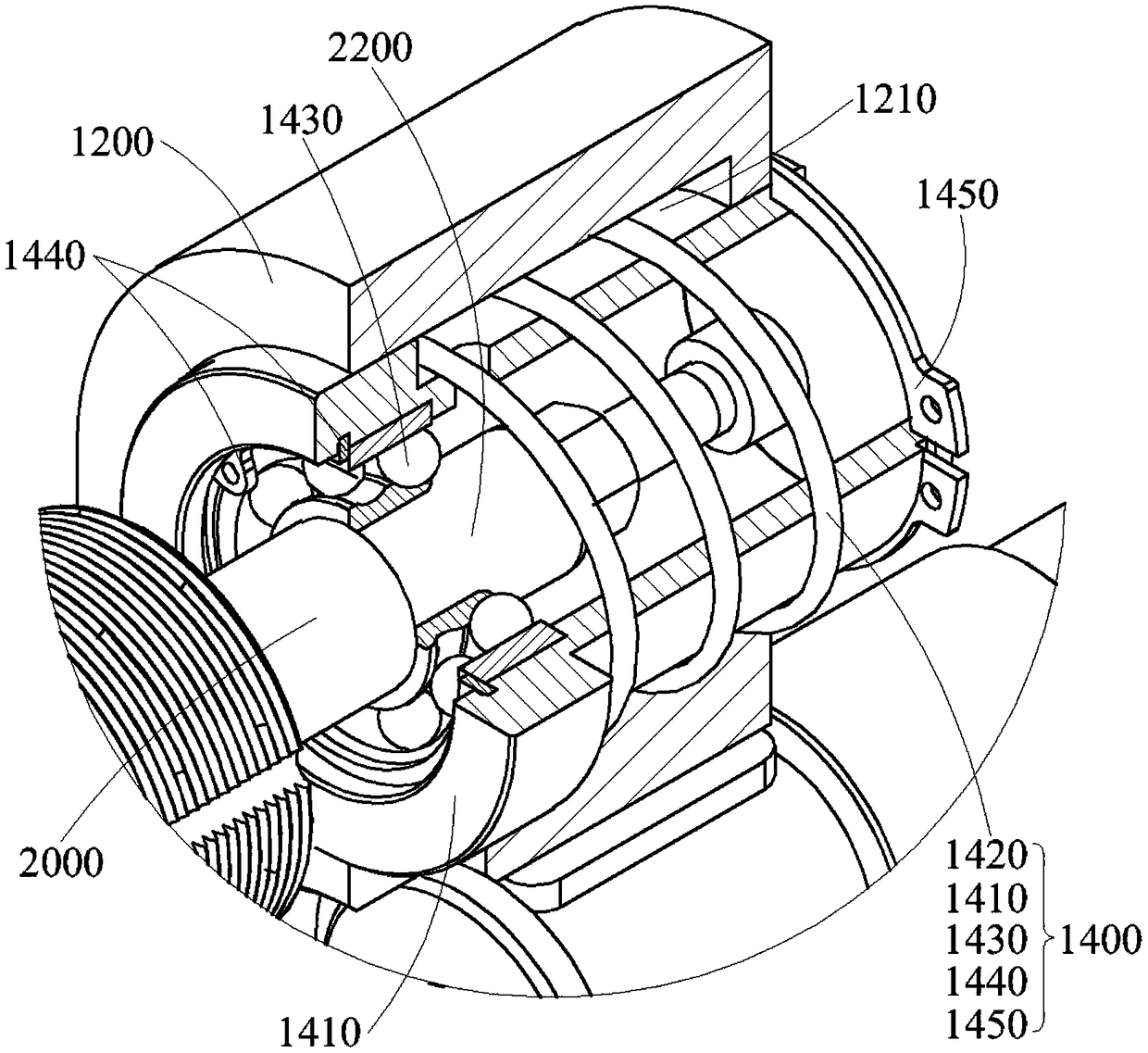

[0033] Please refer to Figure 1~4 , this embodiment discloses a quick self-locking device 1000, including a first support end 1100, a circumferential locator 1300, a second support end 1200 and an axial locator 1400, to realize automatic positioning and locking of the working shaft 2000 with a simplified structure , to ensure positioning accuracy and structural safety, and to compress loading and unloading time to improve production efficiency.

[0034] The first supporting end 1100 and the second supporting end 1200 are located at two ends of the working shaft 2000 for providing end support for the working shaft 2000 . It can be understood that the first supporting end 1100 and the second supporting end 1200 are connected to the frame. It can be understood that the working shaft 2000 is a rotating shaft that rotates to perform a target action, such as a winding shaft, an unwinding shaft, and the like.

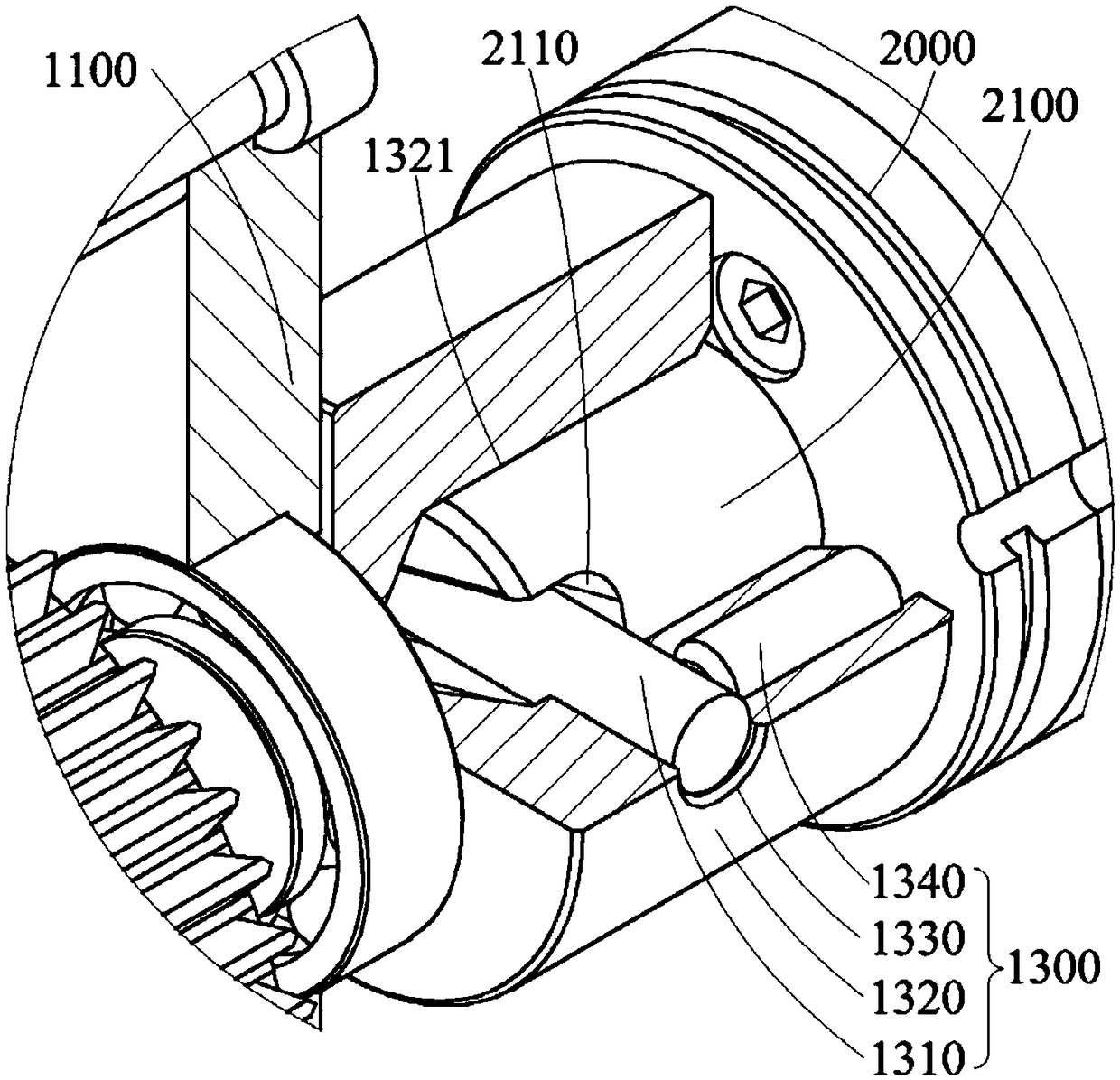

[0035] The circumferential positioner 1300 is rotatably held on the fi...

Embodiment 2

[0053] Please refer to Figure 1~4 , this embodiment discloses a fast self-locking shaft system U, including the working shaft 2000 and the fast self-locking device 1000 introduced in Embodiment 1, and realizes the automatic positioning and locking of the working shaft 2000 with a simplified structure, ensuring positioning accuracy and structural safety Sex, and compress loading and unloading time and improve production efficiency.

[0054] Wherein, one end (first shaft end 2100 ) of the working shaft 2000 is positioned on the circumferential positioner 1300 to achieve circumferential positioning; and the other end (second shaft end 2200 ) is positioned on the axial positioner 1400 to achieve axial positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com