Automatic boring and milling integrated machine tool

A technology of boring and milling and machine tools, which is applied in the direction of boring/drilling, metal processing machinery parts, large fixed members, etc. It can solve the problems of difficulty in meeting modern production, difficulty in mass production, high production cost, etc., and meet the requirements of mass production. The effect of production demand, convenient positioning and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

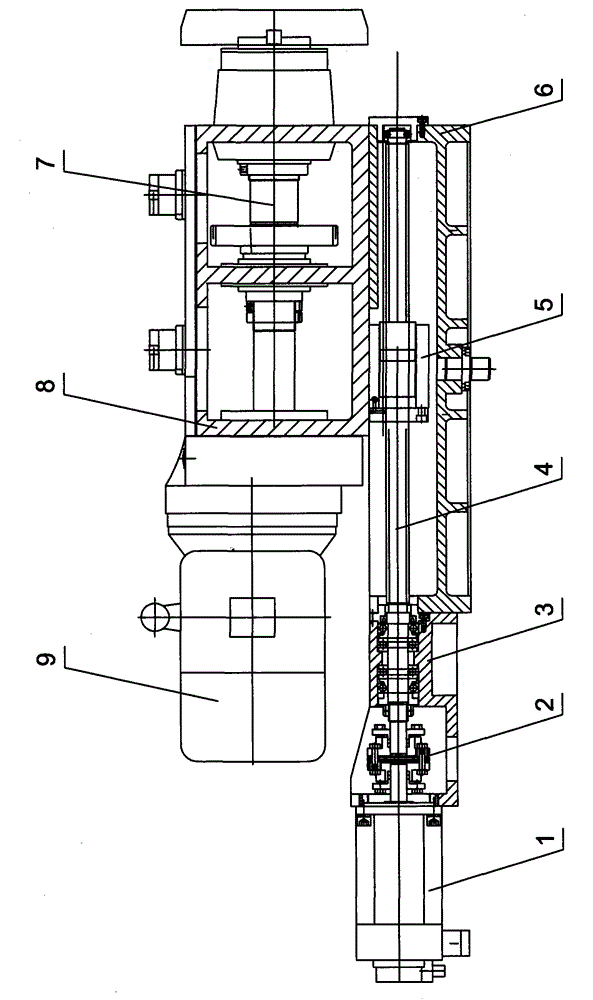

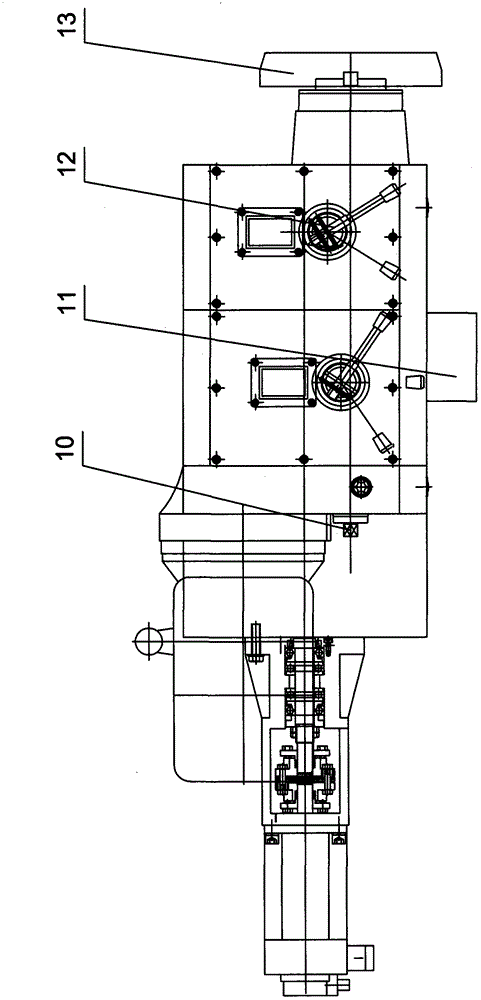

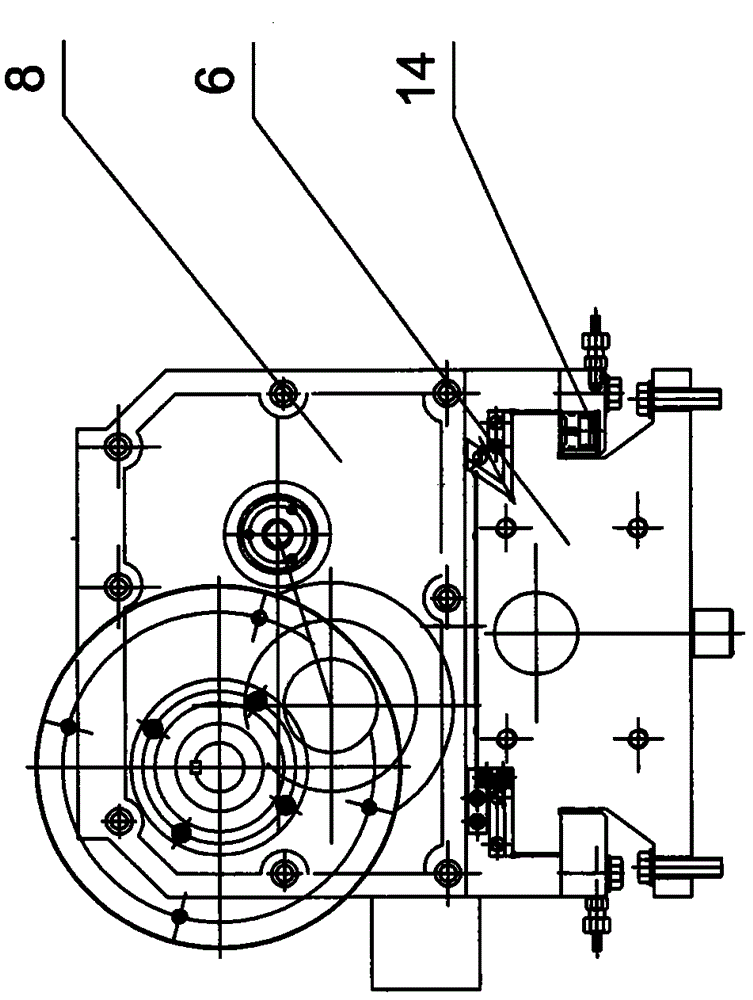

[0013] exist figure 1 , figure 2 , image 3 Among them, the boring and milling machine tool is mainly composed of a special sliding seat and a boring and milling head, and the external connection is a hydraulic station and an electrical control cabinet; the special sliding seat of the boring and milling machine tool is composed of a servo motor 1, an elastic coupling 2, a motor bracket 3, and a ball wire Bar 4, nut bracket 5 and slide body 6, wherein the guide rail on the slide body 6 is a double guide rail structure combining square rail and dovetail guide rail. The specific shape of the double guide rail is that the guide rail on one side is rectangular, and It is dovetail-shaped, and the guide rail of the slider body 6 is provided with a double-nut structure ball screw 4, and the ball screw 4 is provided with a nut bracket 5, and the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com