Tunnel formwork transfer vehicle

A transfer vehicle and formwork technology, applied in tunnels, tunnel linings, lifting devices, etc., to improve work efficiency, save time, reduce extension and retraction time, and provide flexible construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

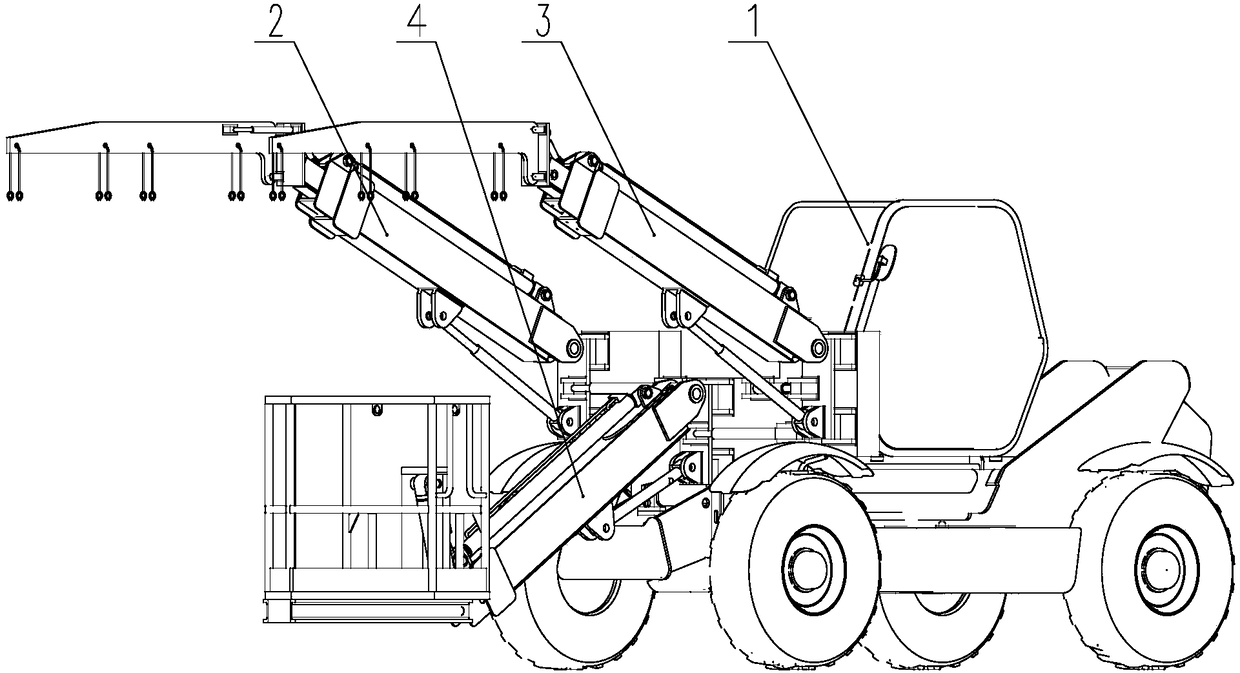

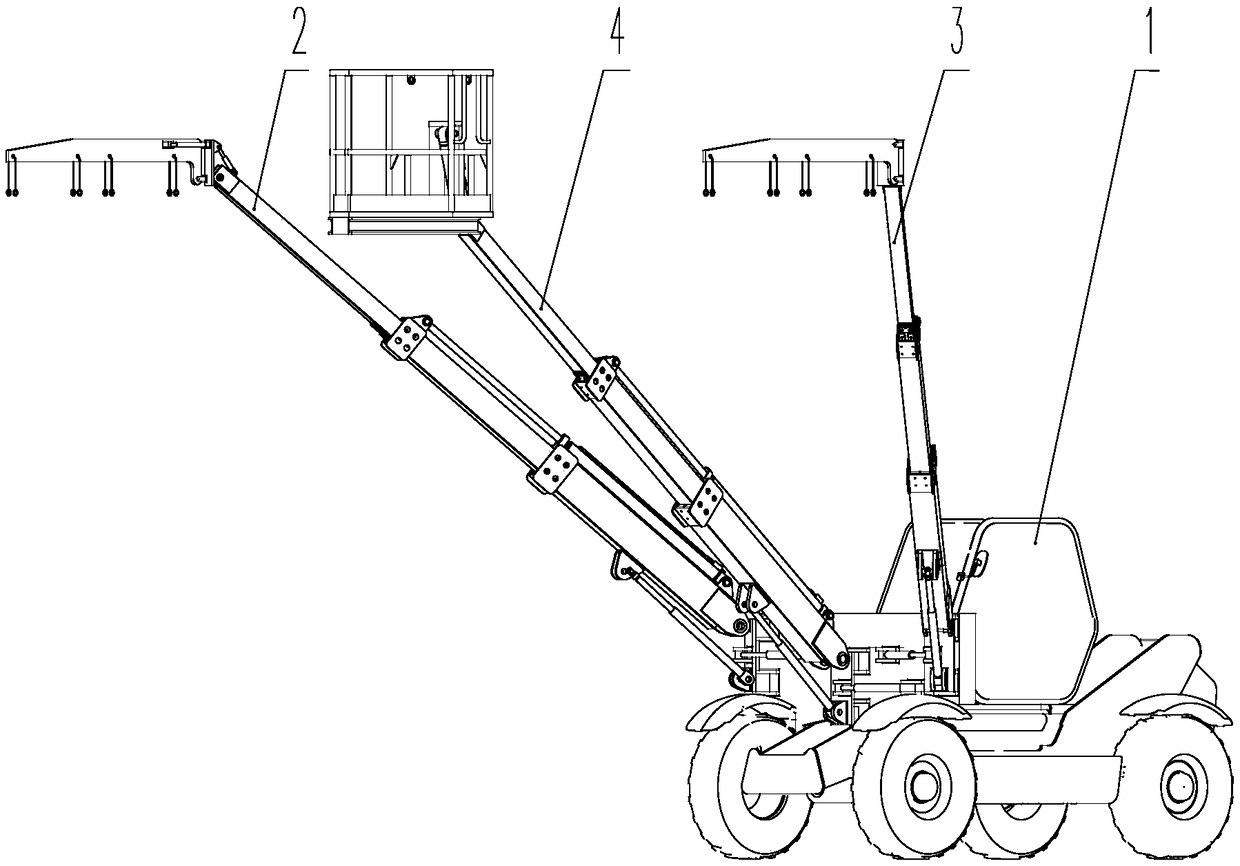

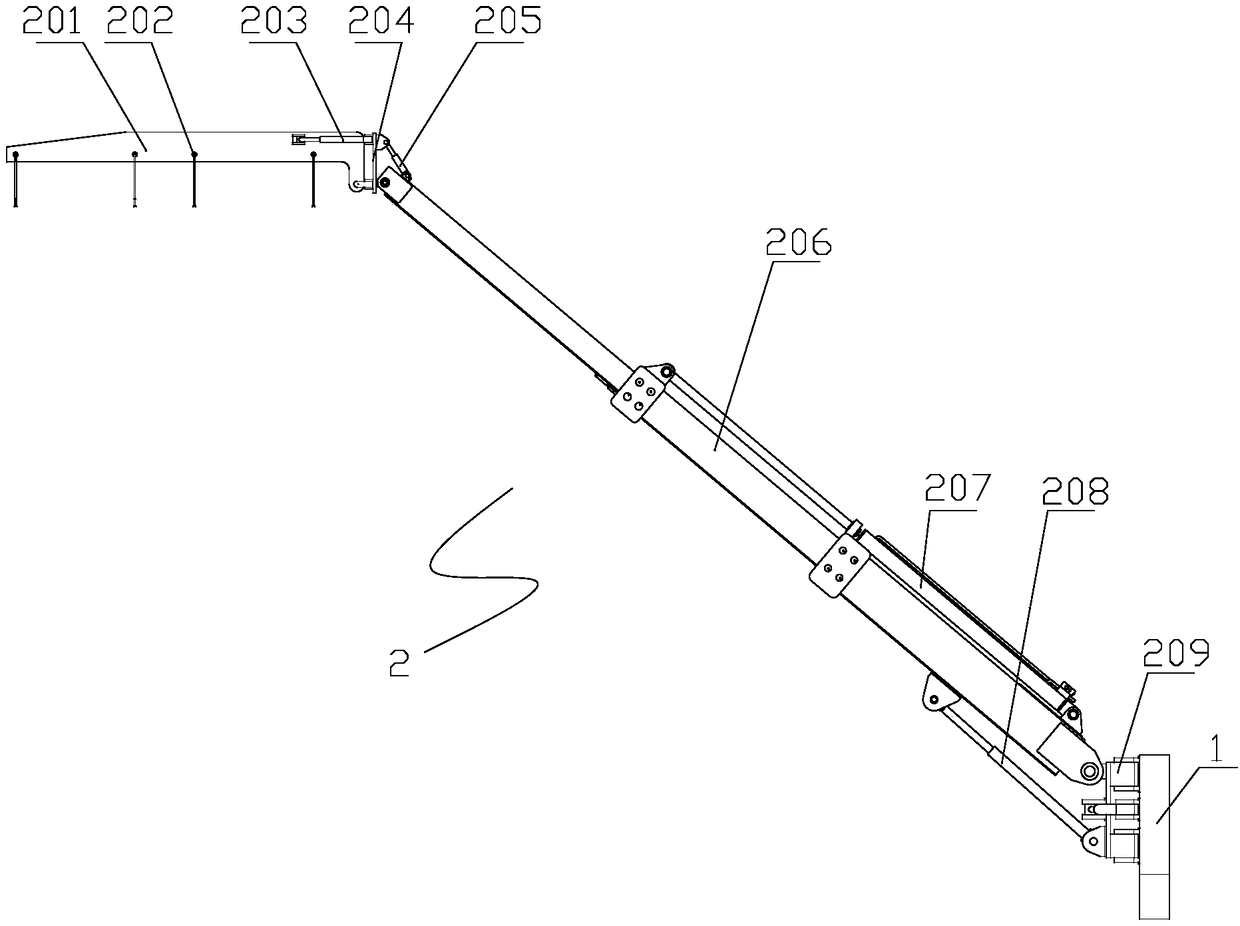

[0032] see figure 1 and figure 2 , the tunnel formwork transfer vehicle shown in the illustration is a preferred solution of the present invention, specifically including a vehicle body 1 , a right lifting arm assembly 2 , a left lifting arm assembly 3 and a hanging basket assembly 4 . The car body 1 can adopt the chassis of wheeled construction machinery, which is convenient to move in the tunnel. The engine and hydraulic system are arranged at the tail end of the car body 1, which can play a certain role in the process of hoisting and transferring the tunnel formwork; the right hoisting The arm assembly 2, the left lifting arm assembly 3 and the hanging basket assembly 4 are respectively connected to the front end of the vehicle body 1 for transfer and installation of the tunnel formwork. The hanging basket assembly 4 is located in the middle of the front end of the car body 1, and the right lifting arm assembly 2 and the left lifting arm assembly 3 are symmetrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com