Gear quenching mechanism and gear quenching method

A technology of gear and drive structure, applied in the field of gear processing, can solve the problems of slow heating speed, easy to produce surface deterioration, poor surface hardness of shaft hole, etc., and achieve the effect of fast heating and cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

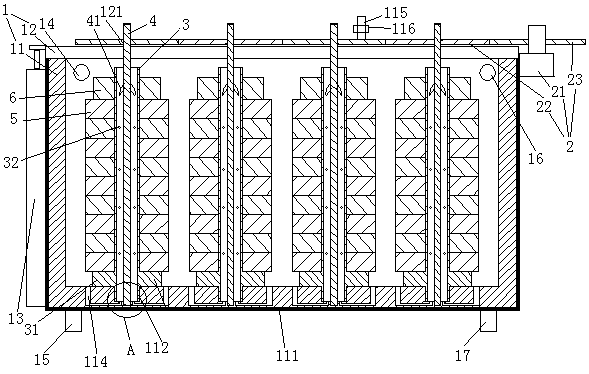

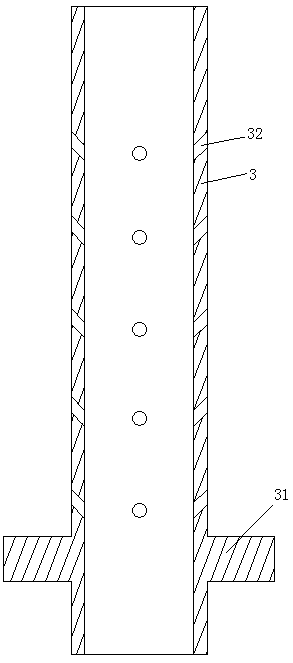

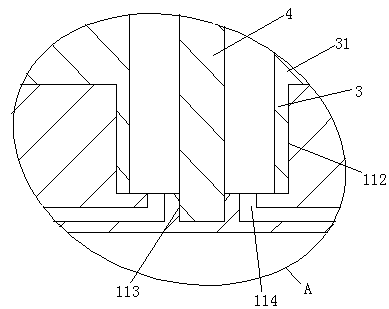

[0019] see figure 1 and figure 2 , a gear quenching mechanism, including a liquid storage tank 1 and a central shaft drive structure 2. The liquid storage tank 1 includes a tank body 11 , a tank cover 12 and an air cylinder 13 for driving the tank cover up and down for opening and closing. The picture of the cylinder block of the cylinder? The two barrels are connected together. The piston rod of the cylinder is connected together with the bung. The outer surface of the bucket body 11 is provided with a thermal insulation layer 111 . The liquid storage barrel is provided with a hot liquid inlet 14 , a hot liquid outlet 15 , a cold liquid outlet 16 and a cold liquid outlet 17 . The bottom wall of the staving is provided with several vertical bearing fixing rods 3 . The bearing fixing rod is a tubular structure. The lower end of the bearing fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com