Assembling type recyclable deep foundation pit support system and construction technology thereof

A deep foundation pit support and assembly technology, applied in infrastructure engineering, sheet pile walls, excavation, etc., can solve problems such as splashing or overflow, no specific guidance plan, and material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

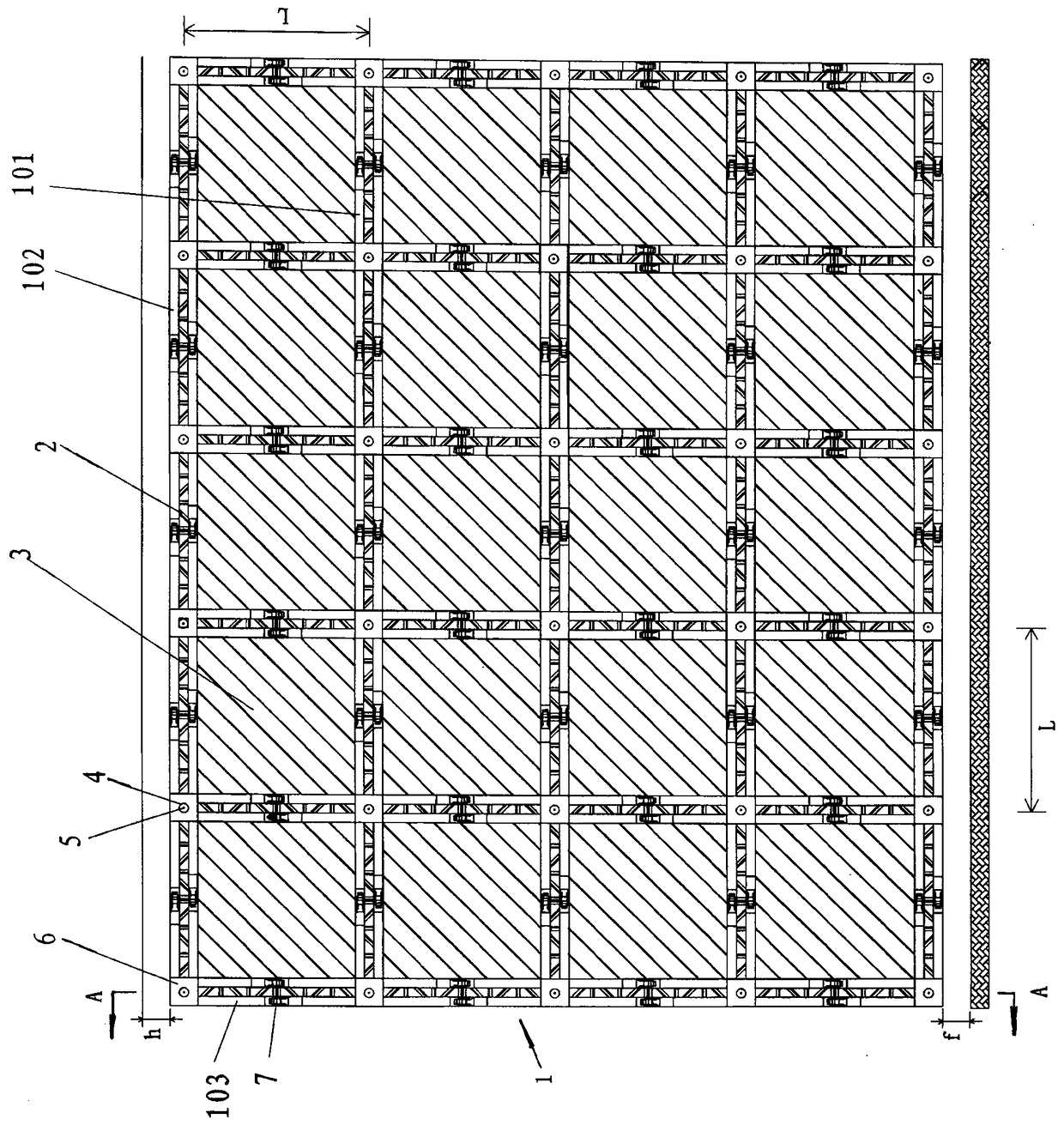

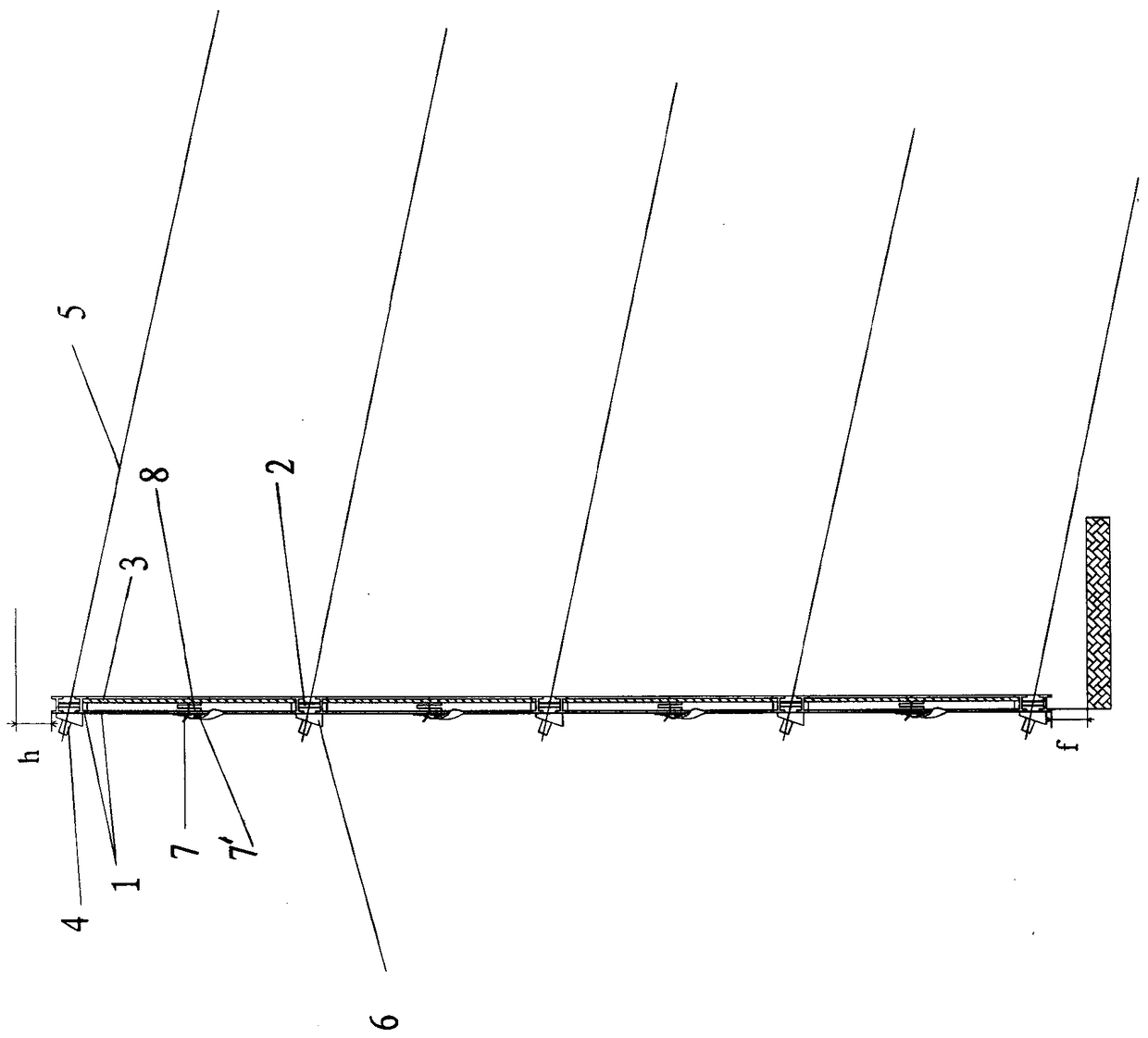

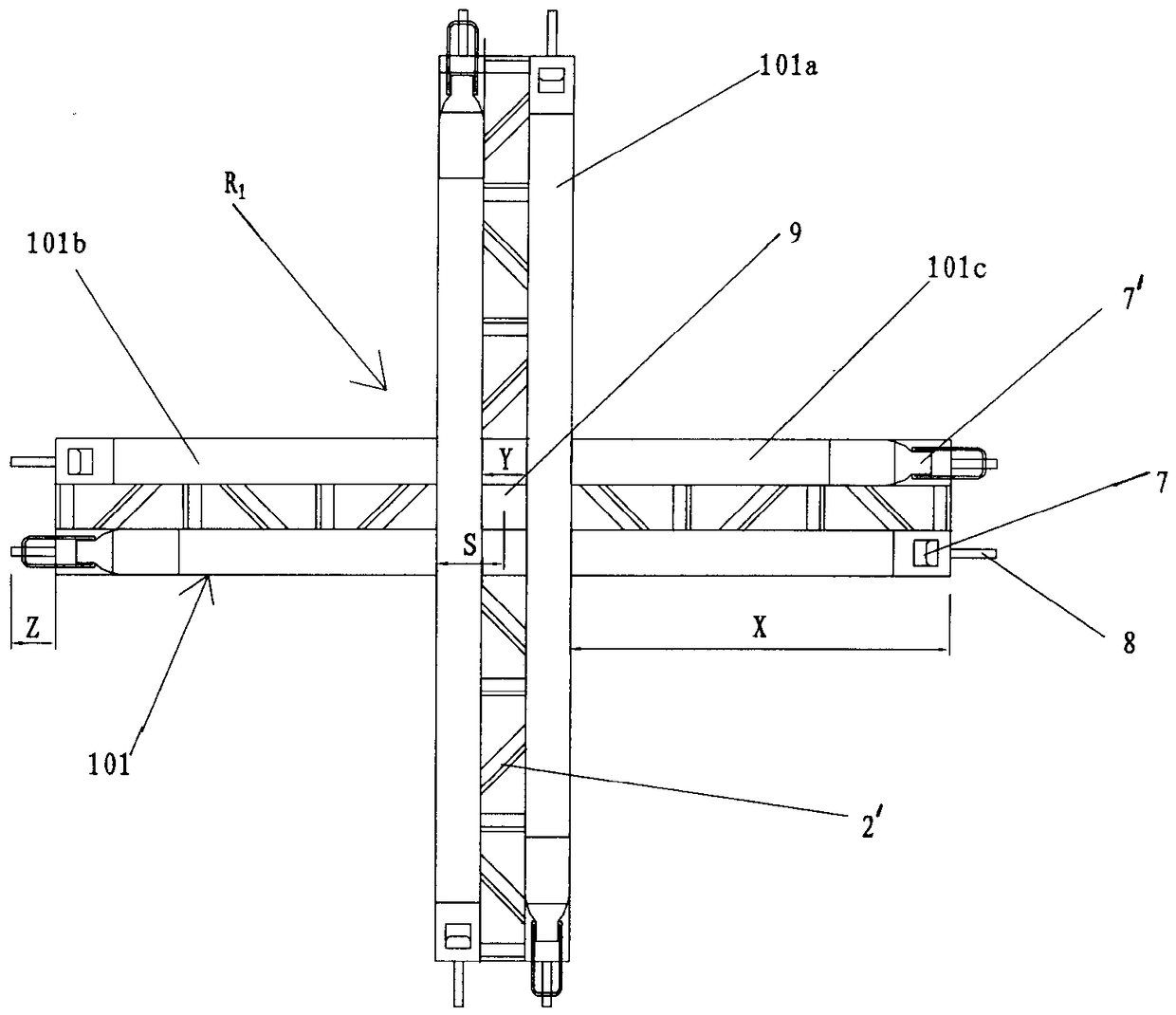

[0037] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the assembled type recyclable deep foundation pit support system of the present invention has an assembled frame 1, a plurality of planks 3 used in conjunction with the assembled frame, and a plurality of backing plates (a plurality of backing plates for anchor rods or anchor cables) 6. One of a plurality of anchor heads 4, anchor rods and anchor cables 5, and the number of the anchor rods and anchor cables is multiple. The assembled frame 1 is composed of a plurality of standard frame units 101 , a plurality of side frame units 102 , and a plurality of corner frame units 103 . Each of the standard frame units 101 has a pair of grooved first section steel 101a arranged vertically, a grooved pair of left section section steel 101b transversely arranged on the left side of the pair of first section steel , a pair of right section sectio...

Embodiment 2

[0043] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown, the construction technique (construction method) of the deep foundation pit support system of assembled type recyclable of the present invention comprises the steps:

[0044] Step 1, digging the foundation pit;

[0045] Step 2: Form the first anchor cable hole, put in the first anchor cable, install the grout stopper, and grout;

[0046] Step 3: Form the second anchor cable hole, put in the second anchor cable, install the grout stopper, and grout;

[0047] Step 4, install the first layer of assembly frame, fasten the horizontal hook fastener of the first layer of assembly frame, that is, make the hook match the collar in the connecting fastener;

[0048] Step 5. Install the wooden board, then install the second layer of assembly frame, fasten the vertical hook fastener of the first layer and the second layer of assembly frame and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap