Bond type connector and bond type steel pipe bundle assembly

A technology of connectors and steel tube bundles, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of waste, unreasonable, thick steel bars, etc., and achieve the effect of saving steel and reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

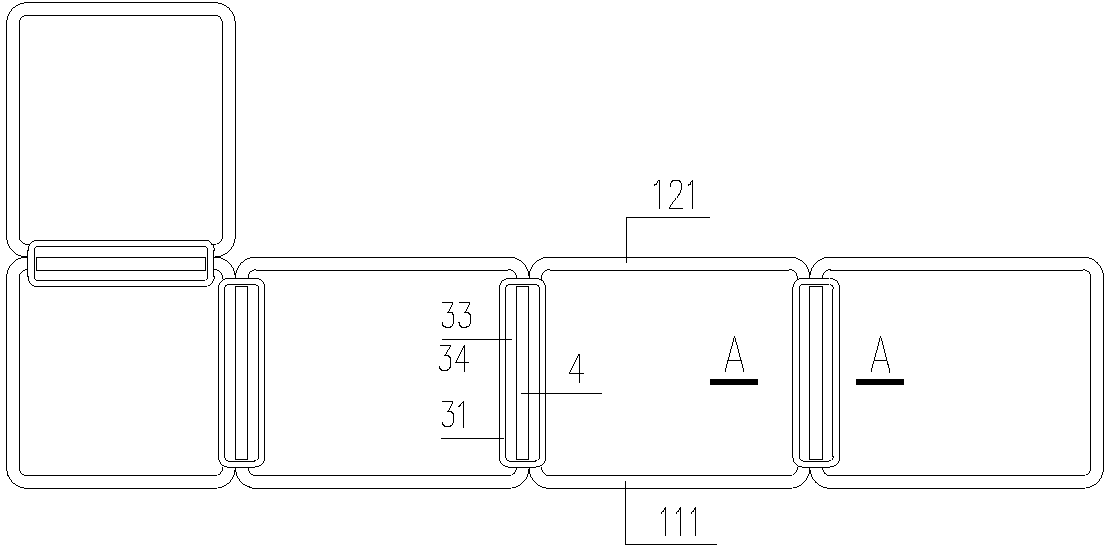

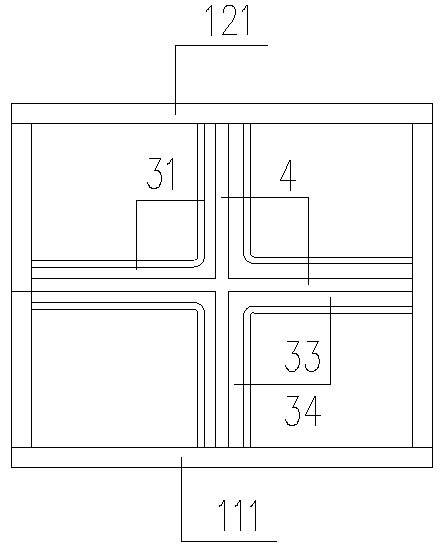

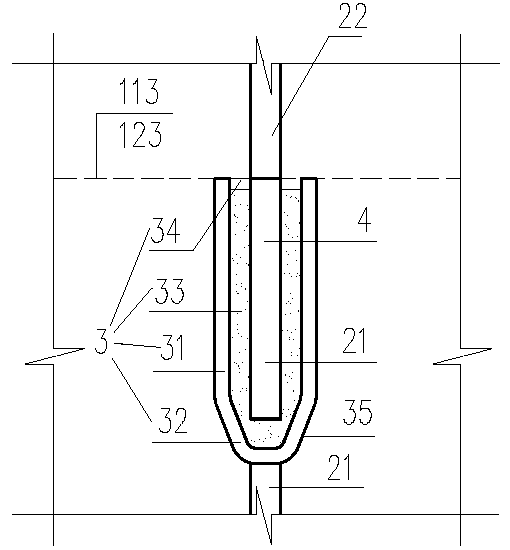

[0024] figure 1 The steel tube bundle shear wall is arranged and connected in sequence with rectangular and plate steel units to form a steel tube with a cavity, which includes the first flange 11, the second flange 12, the web 2, and the web 2 is the adjacent steel tube partition board. Such as image 3 , the webs of the upper and lower steel pipe bundles are connected by bonding, which includes a bag 3, an intermediate piece 4, a lower (steel pipe bundle) web 21, an upper (steel pipe bundle) web 22, and the bag includes closed surrounding sides The wall 31 and the bottom plate 32 are containers with an opening 34 to the top surface of the cavity 33 in the middle; the top surface of the lower web 21 is connected to the bottom surface of the bag, usually by welding, of course, it can also be connected by bolts (the same below); the middle piece 4 is connected to the bottom surface of the upper web 22 (the middle piece 4 can also be an extension of the upper web 22); the cavi...

Embodiment 2

[0035] Such as Figure 4 , U-shaped steel units are arranged in sequence and connected to form a steel tube bundle shear wall. Such as Figure 4 , Figure 5 In the left figure of the left figure, part of the lower web 21 of this example is used as a side wall 37 of the bag 3, and part of the lower first and second flanges 111, 121 are used as the two end side walls 38 of the bag 3; the top of the additional side wall 31 is The inclined surface 36 inclined upwards and outwards can also be a curved surface, and plays the role of guiding the middle piece 4 . Other and embodiment 1 figure 1 , 3 same as the description.

Embodiment 3

[0037] In this example, except that the slope 36 is not established, the arrangement of the bag is the same as that in Embodiment 2. If so Figure 4 The two ends sidewall 38 of bag 1 is provided with grouting hole 5; And as Figure 5The cover 6 shown in the right figure is fixed on the middle piece 4, and can also be fixed on the upper surface of the side wall of the bag 1. The middle piece 4 extends into the cavity, and the cover 6 blocks or tightly closes the opening 34 to prevent concrete from entering; Cover 6 adopts spring sheet, fits better, also can adopt other metal sheet or rubber strip, or spring sheet and rubber strip combination; Then weld connection line 113,123; Then, pour concrete in the cavity of steel pipe bundle; The grout hole 5 is poured with structural glue or other adhesives to fill the cavity 33 and the space under the cover 6 .

[0038] Because the adhesive is welded first and then poured, general adhesives can be used.

[0039] Certainly, embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com