Self-cleaning bus stop

A bus station, self-cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, special buildings, etc., can solve the problems of increased labor for cleaning personnel, hidden safety hazards, and low cleaning efficiency, and save labor. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below.

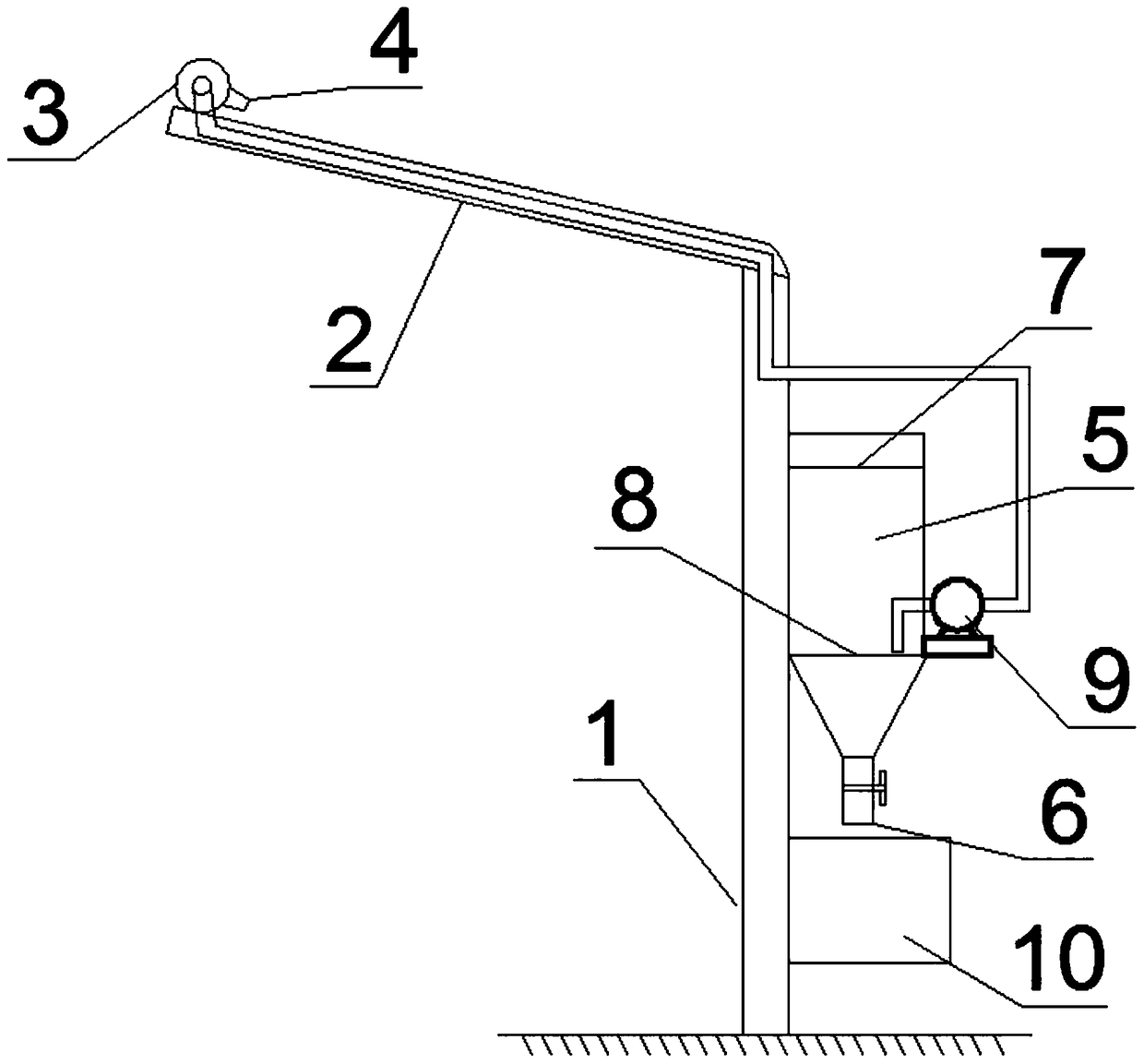

[0015] Such as figure 1 As shown, a self-cleaning bus stop platform includes a stand 1 fixedly arranged on the ground. One end of the ceiling is arranged obliquely, and a water spray pipeline 3 is fixedly connected to the upper part of the ceiling 2 away from the stand 1; the length direction of the water spray pipeline 3 is the same as the length direction of the ceiling 2;

[0016] The lower right part of the water spray pipeline 3 is evenly provided with a plurality of water spray nozzles 4 along the length direction of the water spray pipeline 3 at the position facing the ceiling 2;

[0017] On the side of the stand 1 far away from the ceiling 2, a water collection tank 5 with an open upper end is fixedly connected. 6 is provided with a stop valve;

[0018] A first filter screen 7 is arranged inside the upper opening end of the water collection tank 5, and a second filter screen 8 is provided on the part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com