A turbine baffle with built-in insulation pipe

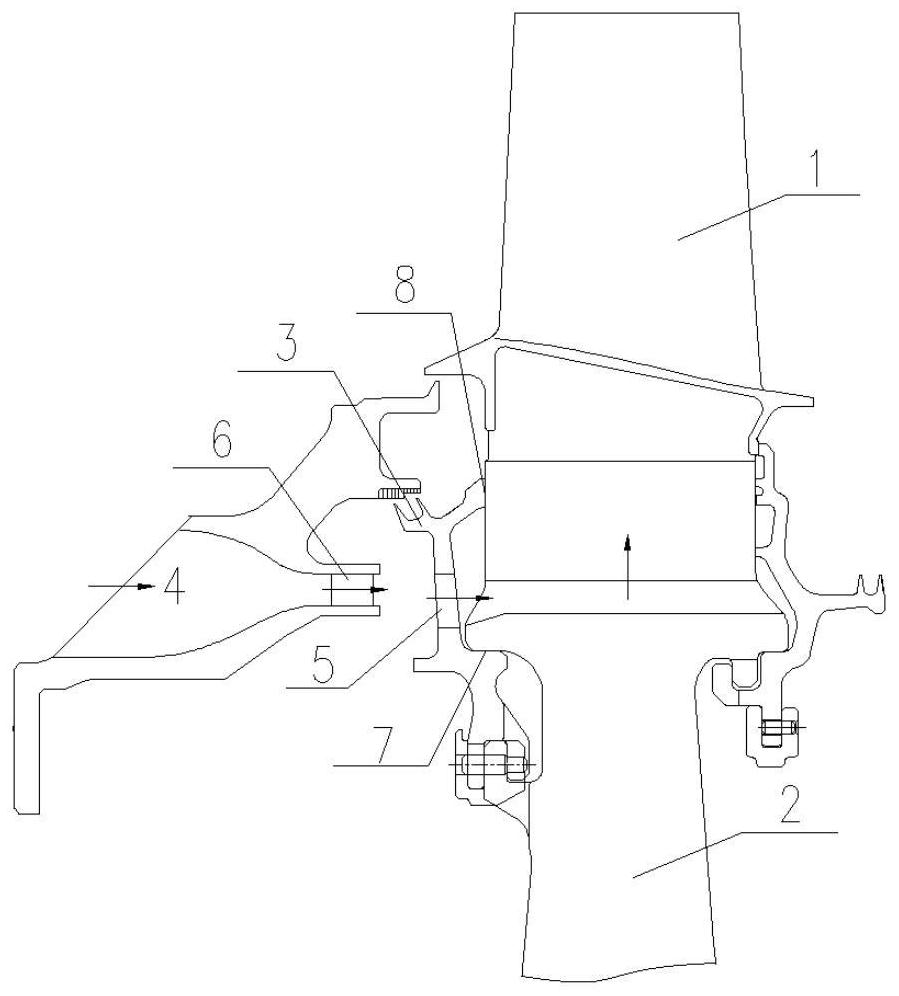

A technology for heat preservation pipes and turbines, applied in the direction of supporting elements of blades, machines/engines, mechanical equipment, etc., can solve the problems of separation of turbine baffles and wheel positioning surfaces, etc., to slow down thermal response speed, reduce residual deformation, The effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

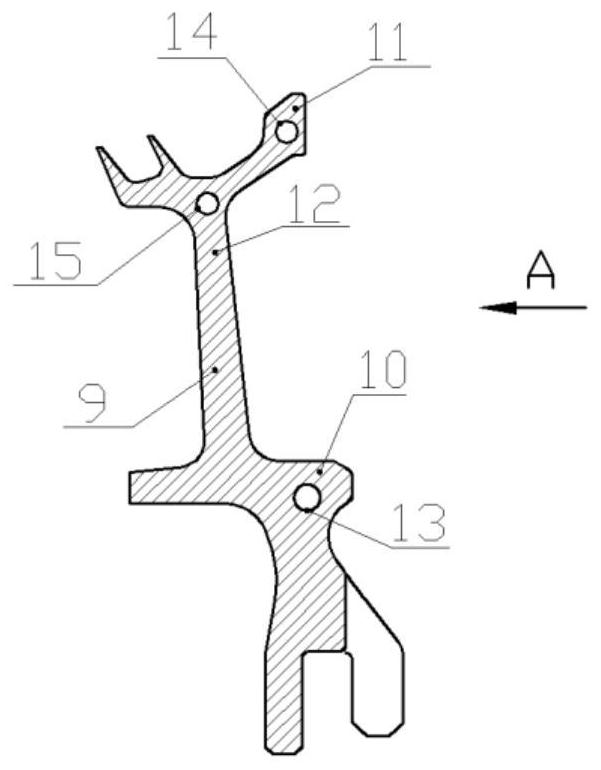

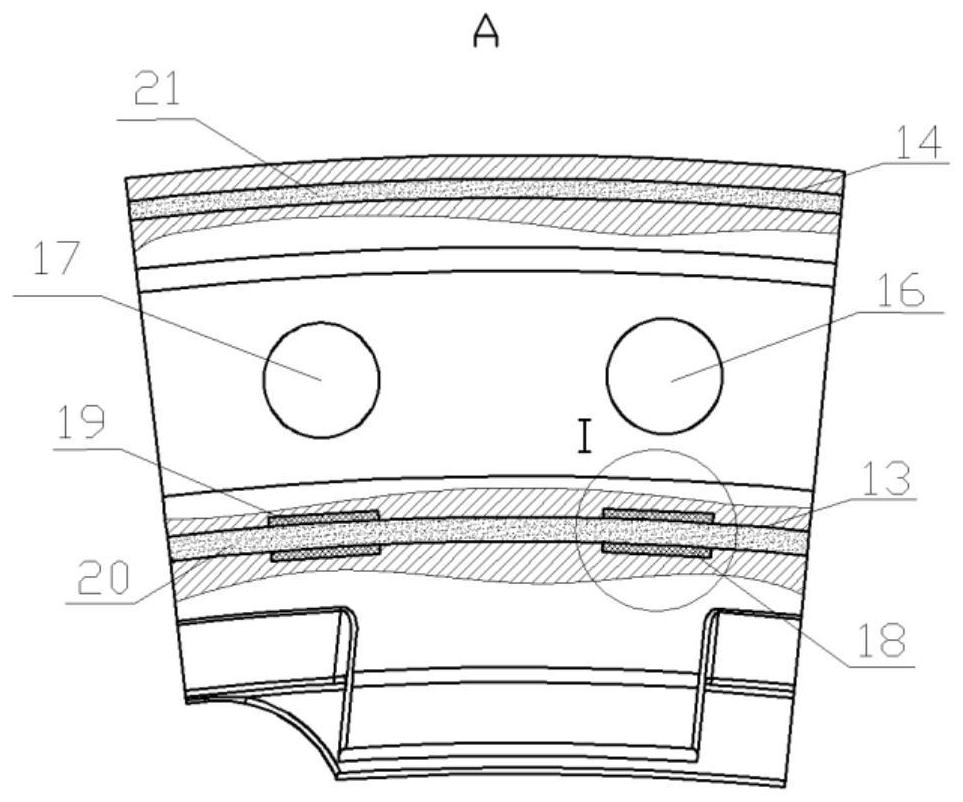

[0020] Such as Figure 2-Figure 4 As shown, a cavity 13 is processed in the radial positioning boss 10 of the built-in insulation tube turbine baffle 9 of the present invention, the cavity 13 extends along at least the circumferential direction, and a certain amount of heat preservation medium 20 is injected into the cavity 13, Form the insulation tube. On the outer surface of the cavity 13 in the radial positioning boss 10, a section of slow-release sleeve 18 or 19 whose thermal conductivity is lower than the material of the turbine baffle is set at a circumferential position corresponding to the turbine baffle air hole 16 or 17, and the slow-release The sleeves 18 or 19 surround at least a part of the circumferential surface of the cavity 13, the number of which is the same as the number of the turbine baffle vents 16 or 17, the length of each section is equal, and they are uniformly distributed along the circumferential direction. When the engine accelerates, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com