Nozzle liquid mist distribution adjustable rocket engine jet faceplate and design method

A rocket engine and nozzle technology, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems affecting the flame shape of the nozzle, combustion instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

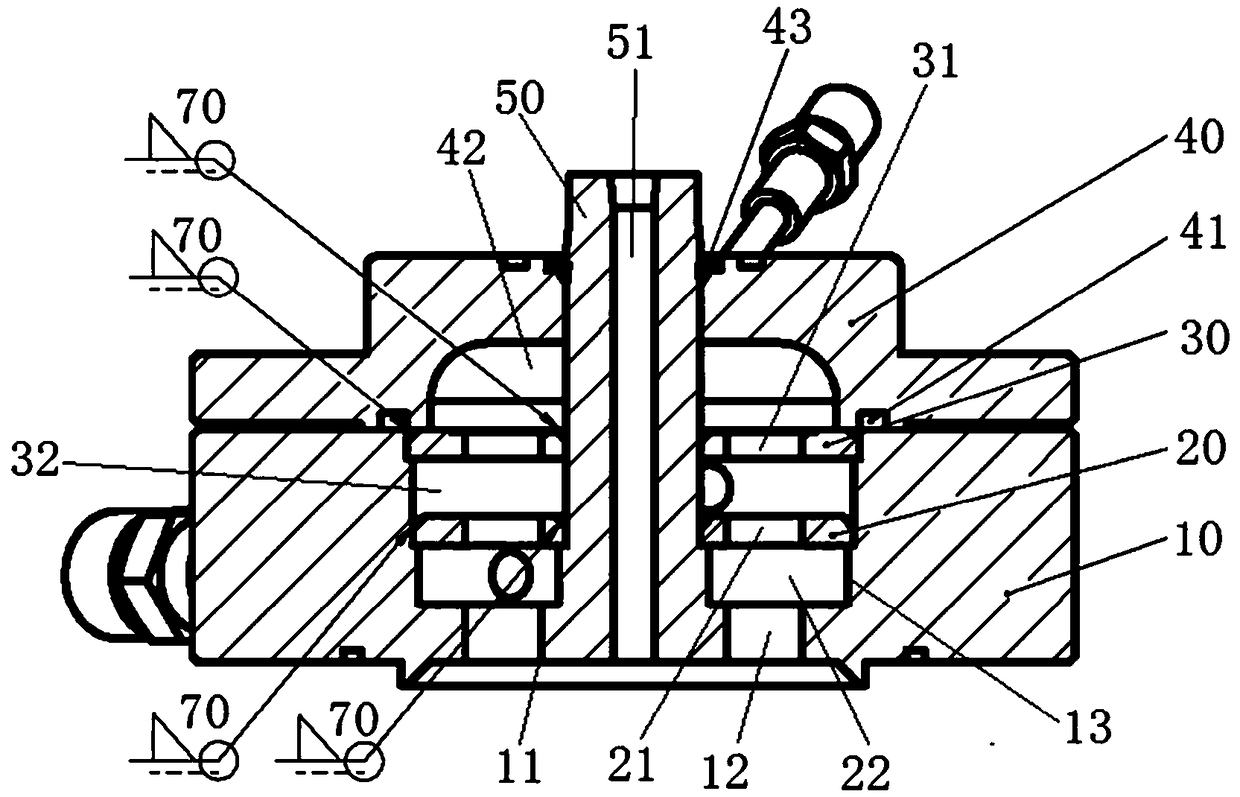

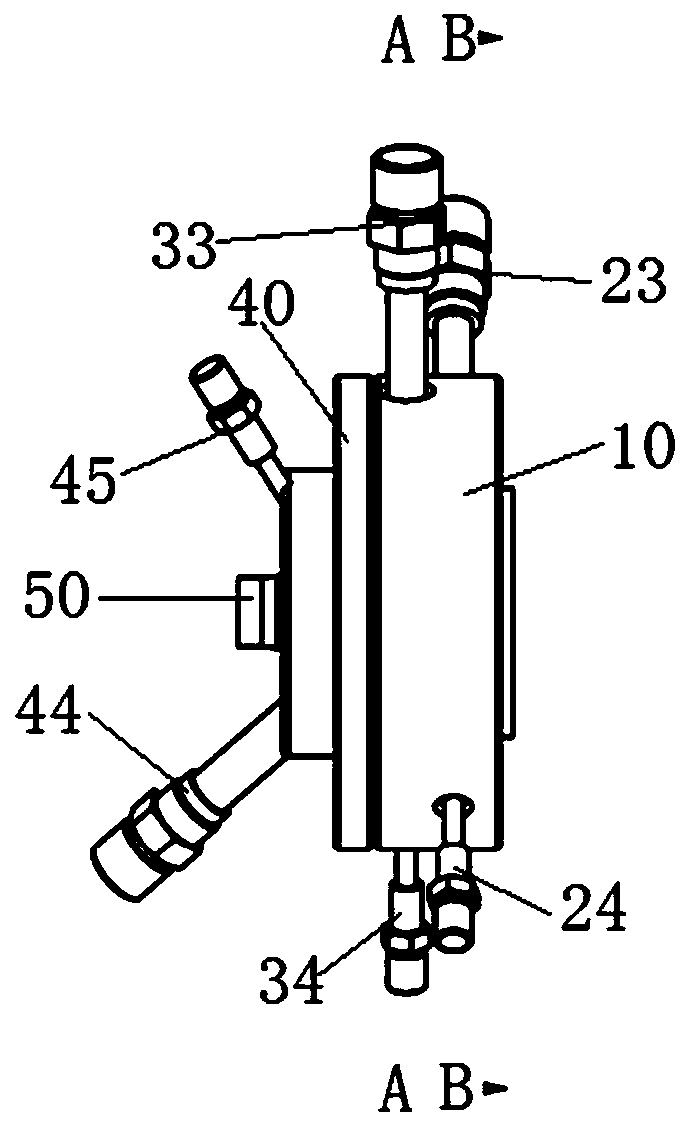

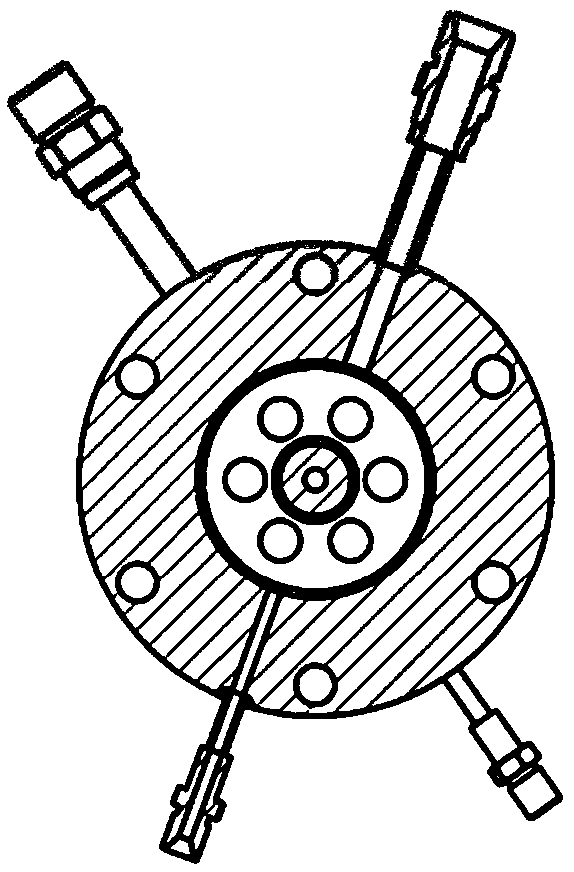

[0085] Such as Figure 1 to Figure 6 As shown, a rocket engine injection panel with adjustable nozzle liquid mist distribution includes a gas collection chamber base 10, a gas collection chamber middle plate 20, a gas collection chamber rear plate 30, a fuel chamber top cover 40, and a fire transfer tube 50 And several double swirl nozzles 60.

[0086] The center of the base of the gas-collecting chamber is provided with an air-collecting chamber 13 with an open top, and the gas-collecting chamber is provided with bottom steps and top-floor steps from the inside to the outside in sequence, and the center of the bottom plate of the gas-collecting chamber is provided with a fire-transfer tube installation hole 11 for fire transmission. The number of nozzle holes 12 equal to the number of double-swirl nozzles is evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com