direct heat burner

A furnace head and direct heating technology, which is applied in the field of induction cooker, can solve the problems of multi-head furnace waste, inconvenience, and limitation of induction cooker, and achieve the effects of cost reduction, rapid temperature control and energy efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is further described:

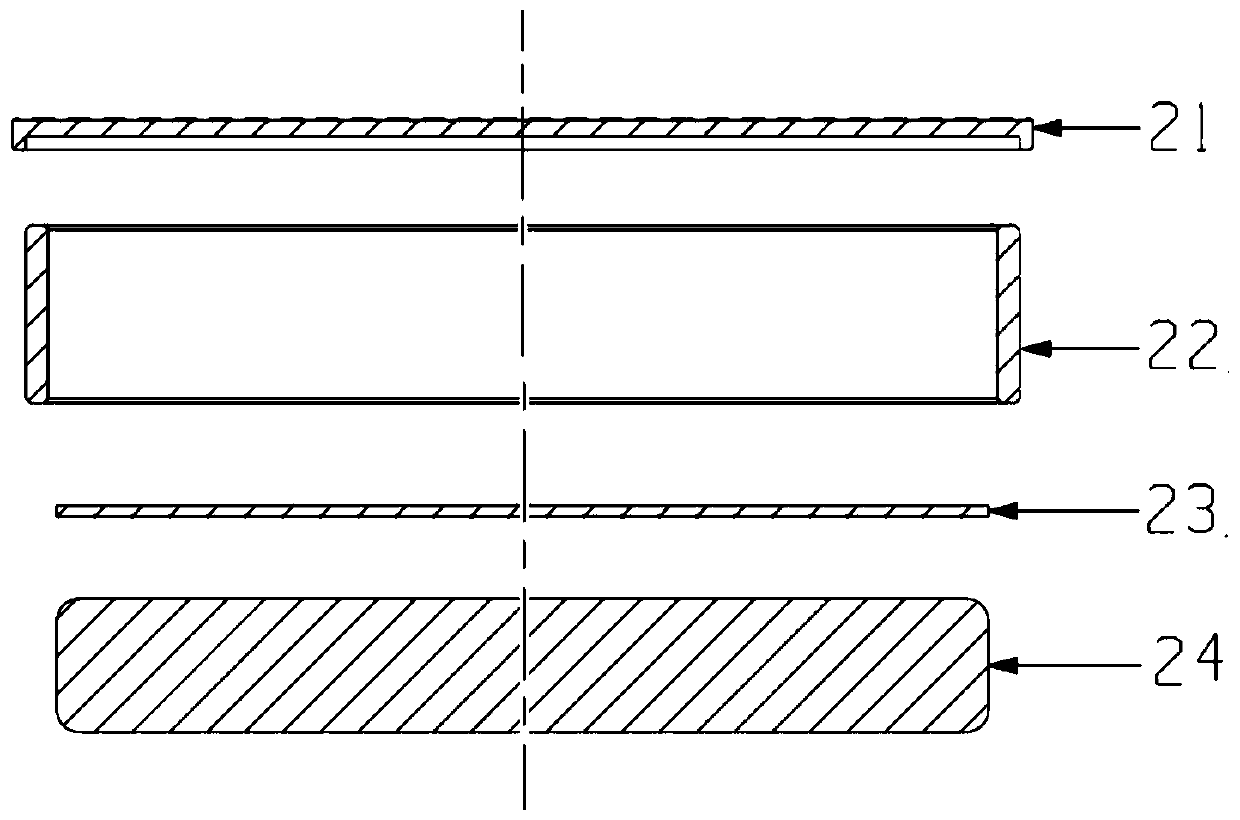

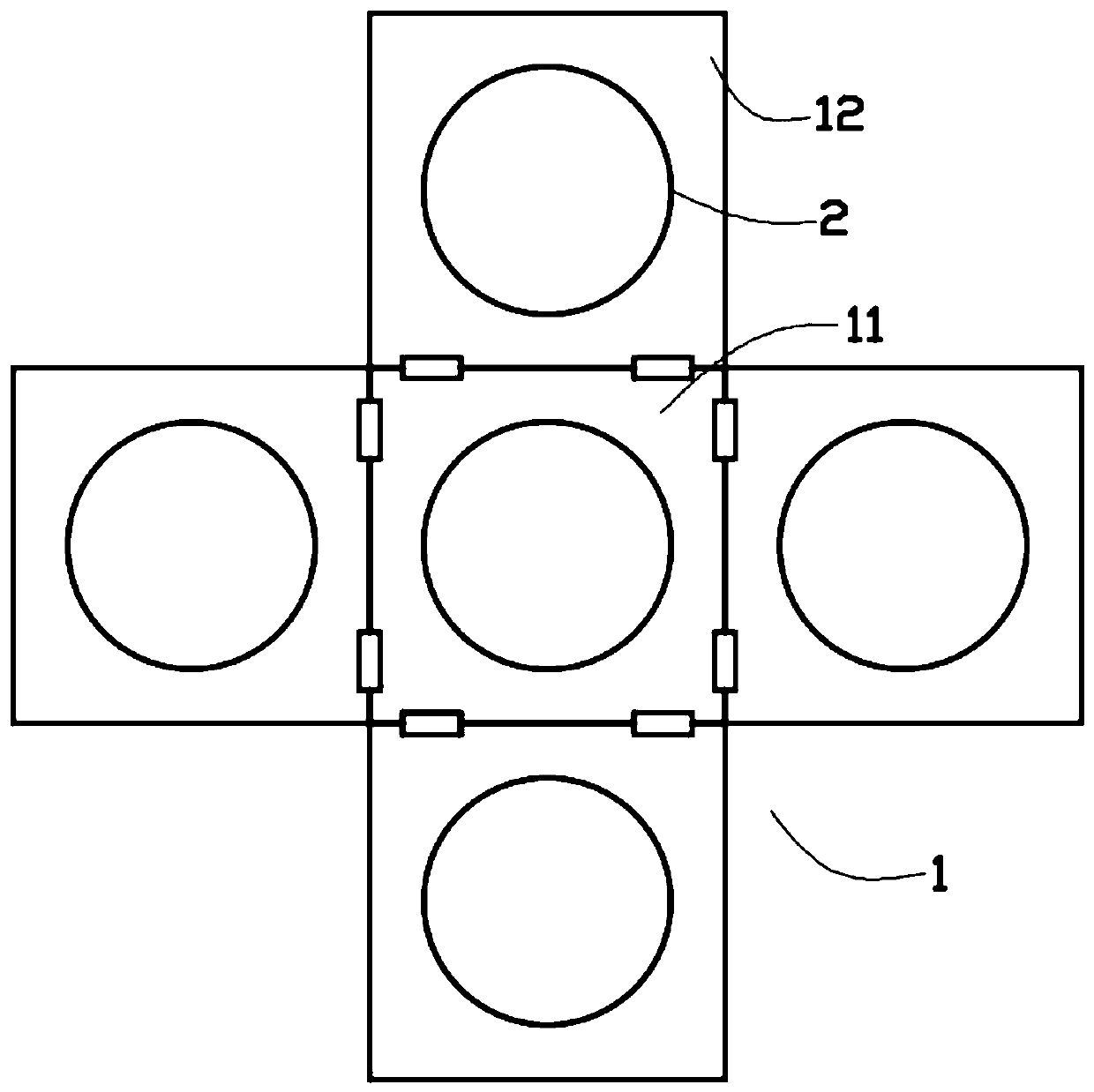

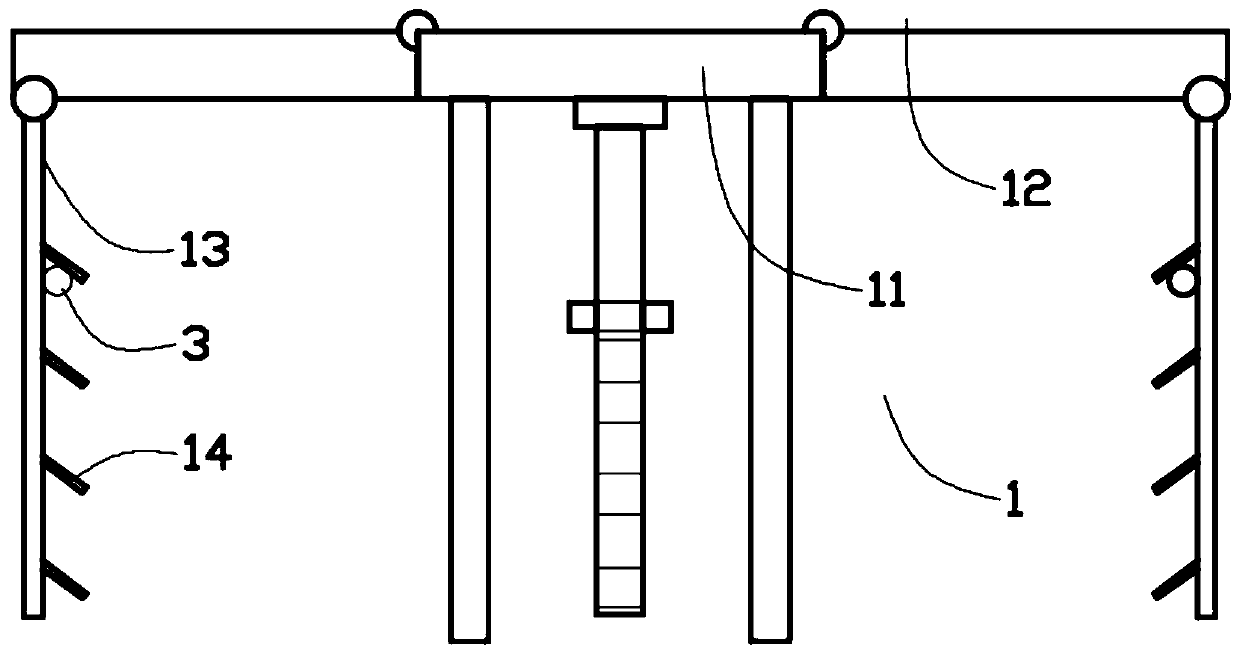

[0019] Such as figure 1 with figure 2 As shown in the embodiment, the direct heating burner includes a furnace base 1 and a burner 2, and the burner 2 includes a heat storage base 21, a protective cover 22, a heat insulation sheet 23, and a heating base 24; the protective cover 22 is designed It is ring-shaped, and the protective cover 22 is made of antimagnetic and waterproof material. The heat storage base 21 is designed as a flat sheet, which is covered and assembled on the upper part of the protective cover 22. The heat storage base 21 is made of metal material, and the heating The base 24 is assembled in the protective cover 22, the inside of the heating base 24 is equipped with a heating coil, the heat insulating sheet 23 is made of heat insulating material, and the heat insulating sheet 23 is sheet-shaped, and the heat insulating sheet 23 It is assembled between the heat storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com