Microhardness indentation measurement method based on confocal principle

A microhardness and measurement method technology, applied in the direction of testing material hardness, etc., can solve the problems of large personnel errors, inability to measure, and large influence of light source illumination intensity, etc., achieve high resolution, improve measurement accuracy, and ensure measurement accuracy Effect

Inactive Publication Date: 2019-02-22

BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Using an optical microscope to directly measure the indentation diagonal, its measurement accuracy, degree of automation and measurement efficiency can no longer meet the requirements, and the introduction of personnel errors is also greater; the way of CCD image acquisition and processing is due to the impact of light source illumination intensity on The impact of image formation is large, which makes it impossible to measure under small indentations with diagonal lines less than 20μm

In addition, since the two traditional methods cannot analyze the protrusion changes at the edge of the micro-hardness indentation image, neither can achieve accurate measurement of the micro-hardness indentation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

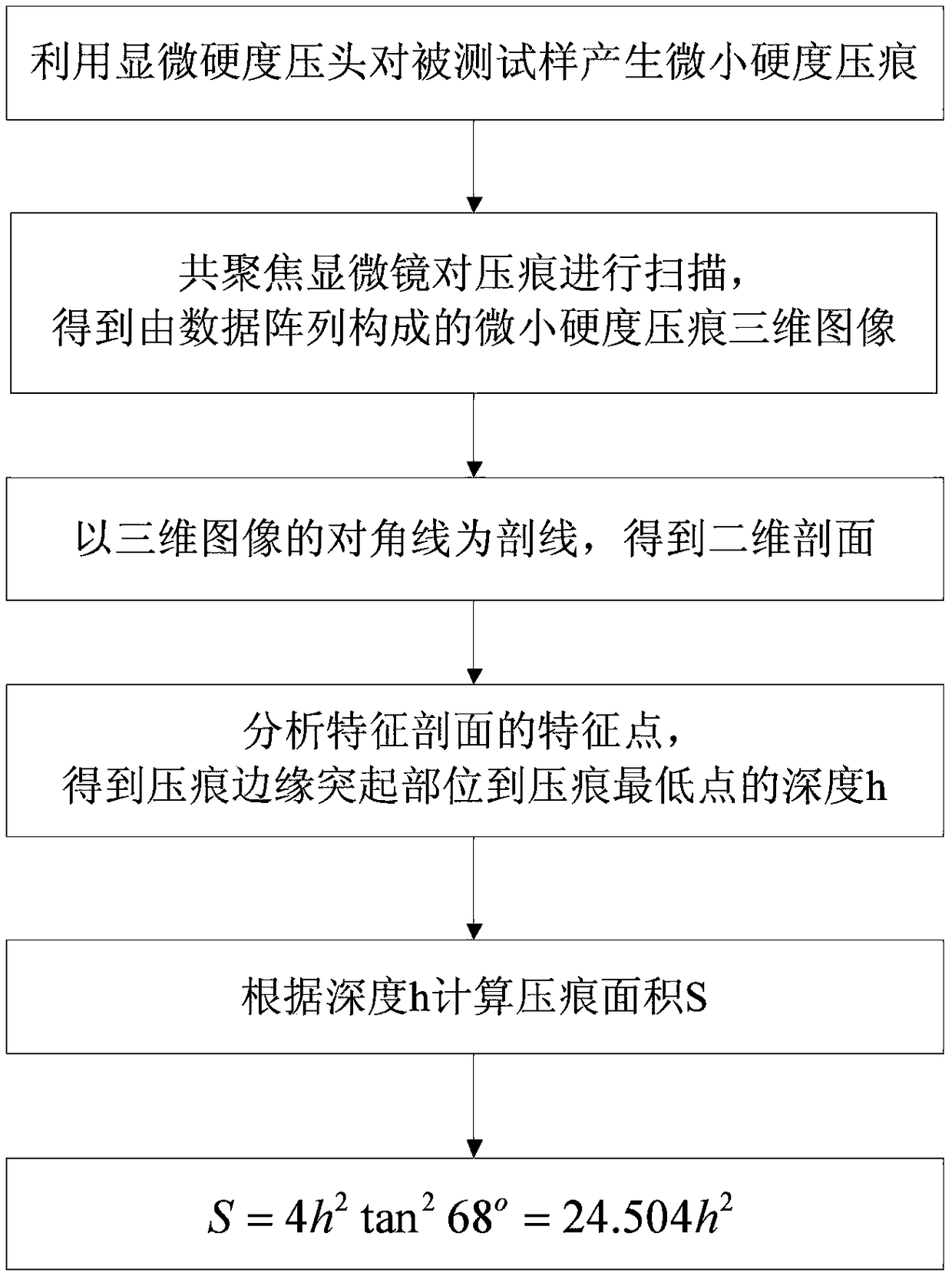

[0027] Such as figure 1 As shown, a method for measuring micro-hardness indentation based on the confocal principle disclosed in this embodiment, the specific implementation steps are as follows:

[0028] Step 1: Use the microhardness indenter to make tiny indentations on the tested object.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

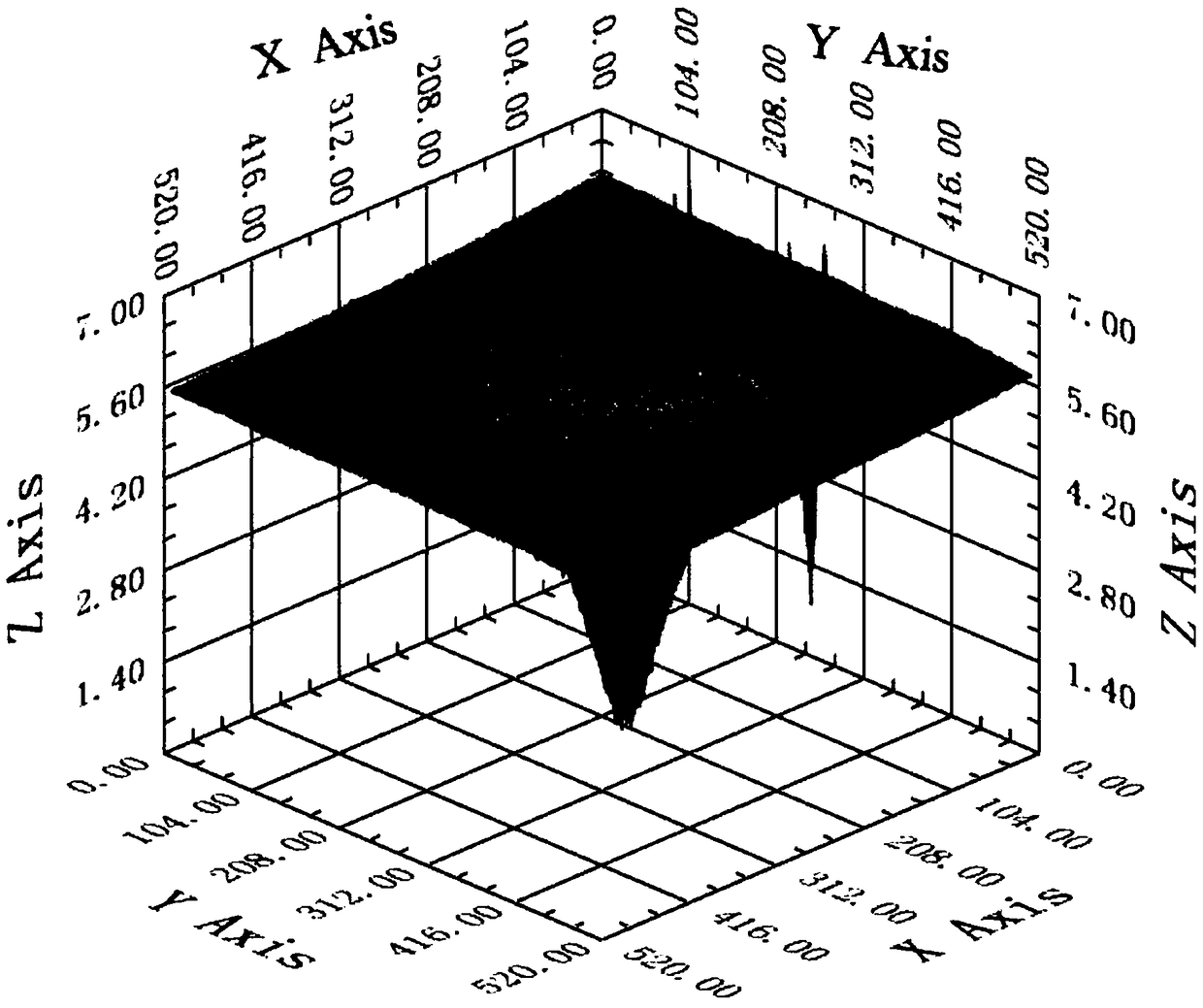

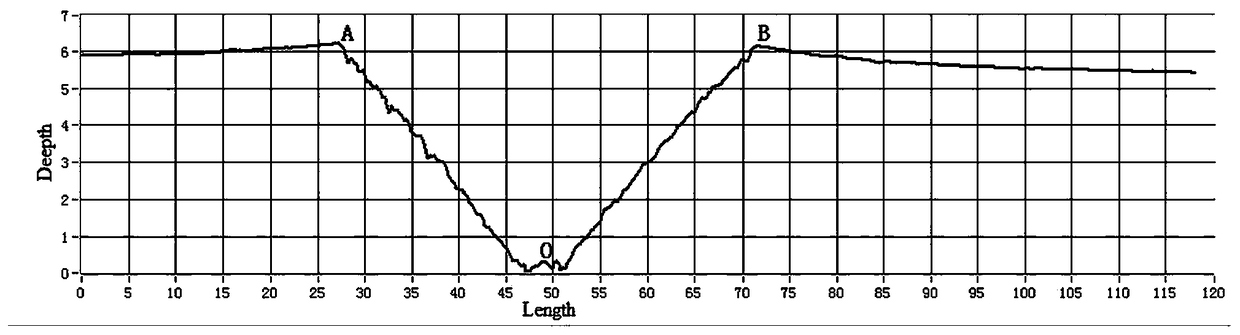

The invention discloses a microhardness indentation measurement method based on a confocal principle and belongs to the field of hardness metering. The method comprises the steps of pressing a micro indentation on a measured sample through a microhardness pressing head, performing three-dimensional scanning measurement on the microhardness indentation through a three-dimensional measurement function of a confocal microscope, obtaining a three-dimensional image of the microhardness indentation formed by a data array, obtaining a two-dimensional feature section of the three-dimensional image bytaking a diagonal line of the indentation as a section line, obtaining depth h from a bulge on the edge of the indentation to a lowest point of the indentation by analyzing a feature point of the feature section, substituting the depth h of the indentation into an algorithm formula to calculate the area of the microhardness indentation, and achieving the measurement of the microhardness indentation. The method can achieve the measurement of the microhardness indentation with the indentation diagonal line of less than 20 micrometers. The method is not influenced by an illumination intensity variation, can effectively identify a bulge state of the edge of the indentation, is high in resolution in Z direction and ensures measurement precision.

Description

technical field [0001] The invention belongs to the field of hardness measurement, in particular to a method for measuring tiny microhardness indentations based on the confocal principle. Background technique [0002] For the measurement of microhardness indentation, the traditional optical microscope or CCD image acquisition and processing methods are generally used to obtain the length of the two diagonals of the microhardness indentation, and then the projected area of the microhardness indentation is calculated by the formula. As for the tiny microhardness indentation, the indentation diagonals are all less than 20 μm, touching the limits of the two traditional indentation measurement methods. Using an optical microscope to directly measure the indentation diagonal, its measurement accuracy, degree of automation and measurement efficiency can no longer meet the requirements, and the introduction of personnel errors is also greater; the way of CCD image acquisition and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/42

CPCG01N3/42

Inventor 石伟陶继增李杨

Owner BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com