Heat dissipation structure and heat dissipation method for metal fuel cells

A metal fuel cell and heat dissipation structure technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of unsatisfactory heat dissipation effect, high noise, low space utilization rate, etc., and achieve excellent heat dissipation effect, Reasonable structural layout and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

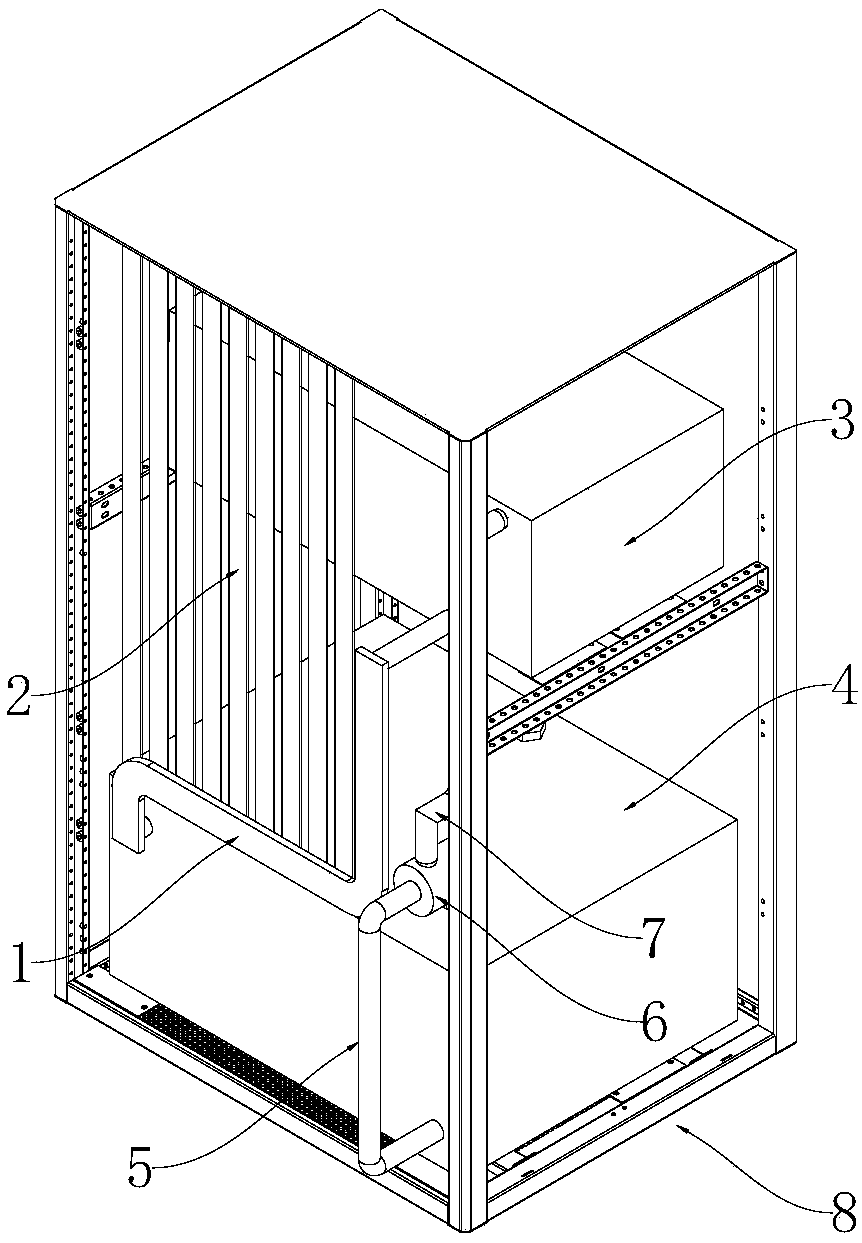

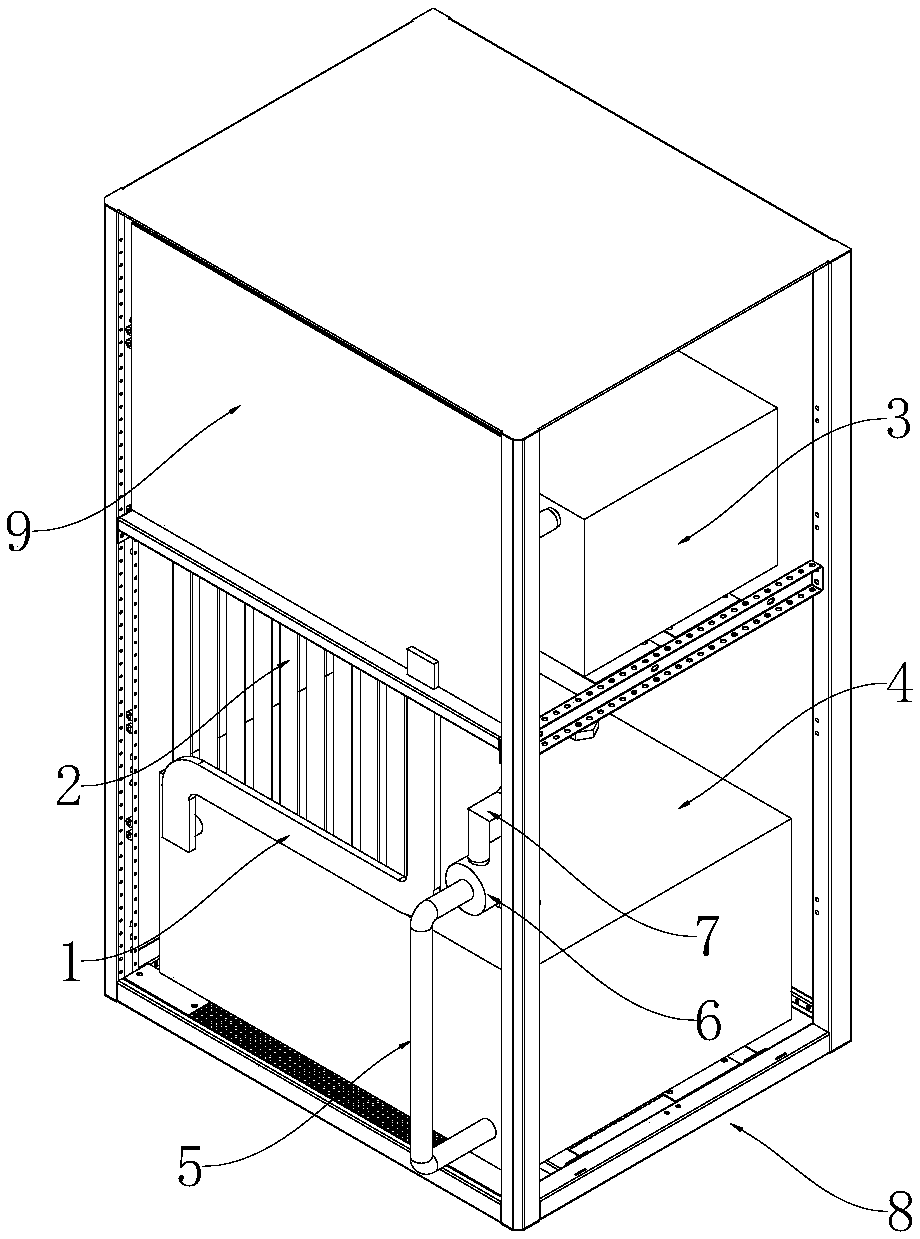

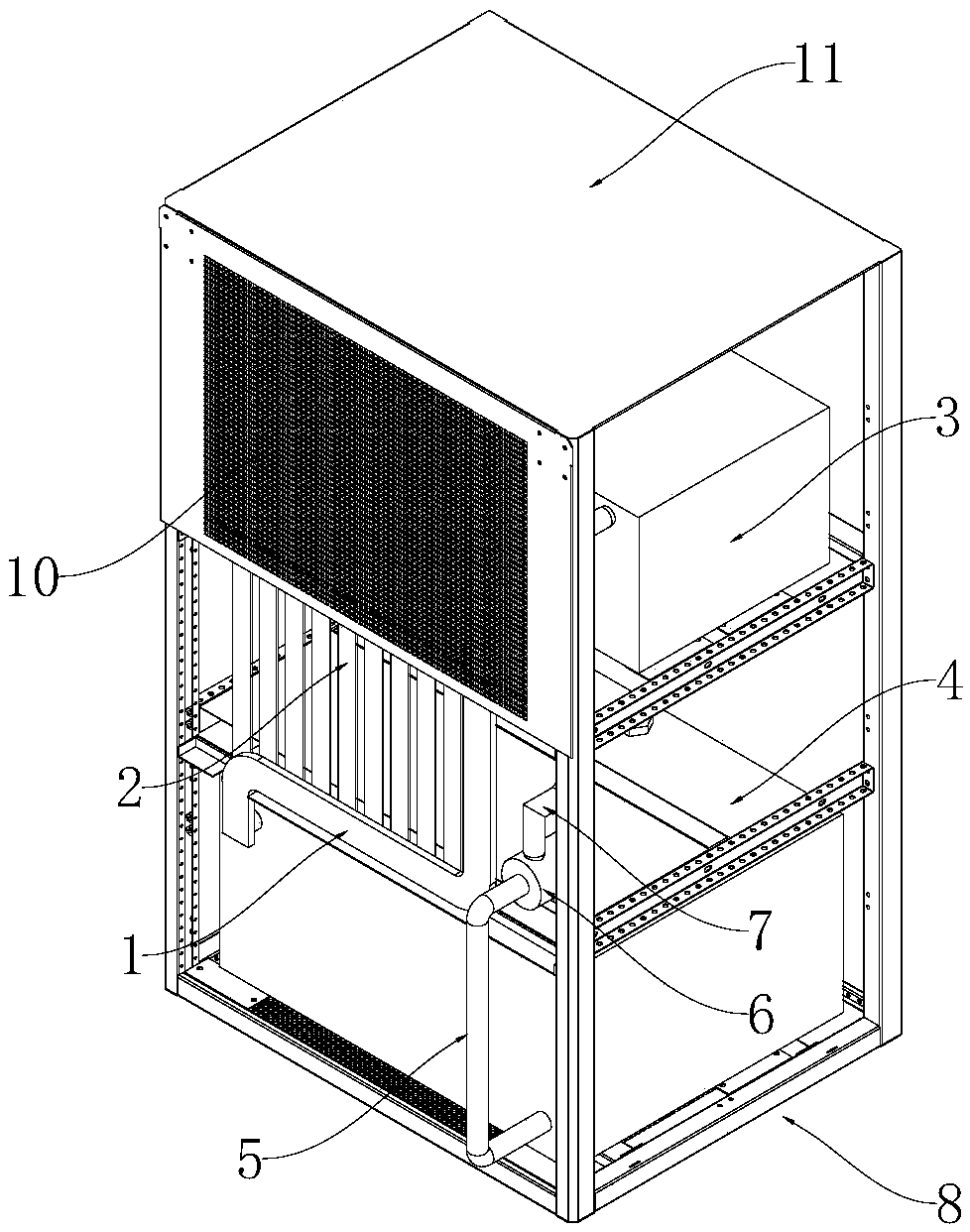

[0045] Such as Figure 1-8 As shown, this embodiment discloses a metal fuel cell heat dissipation structure, and the metal fuel cell involved in the present invention can be an aluminum-air battery, such as figure 1 As shown, the heat dissipation structure includes a flat liquid return pipe 1 and a superconducting flat heat pipe 2. The inlet of the flat liquid return pipe 1 is connected to the liquid outlet of the battery reactor 3, and the outlet of the flat liquid return pipe 1 is connected to the return of the reaction liquid tank 4. The liquid port is connected, and a plurality of superconducting flat heat pipes 2 are bonded to the surface of the flat liquid return pipe 1 through heat-conducting adhesive; Compared with the heat dissipation of the whole reaction liquid box, the present invention only dissipates heat to the liquid flowing through the flat liquid return pipe 1, the heat dissipation effect is better, and the present invention has high reliability, even if one ...

Embodiment 2

[0054] Based on the same inventive concept as Embodiment 1, this embodiment specifically discloses a heat dissipation method for a metal fuel cell. Specifically, the heat dissipation method includes the following steps, such as Figure 8 shown.

[0055] Pumping the reaction solution into the battery reactor 3: under the action of the water pump 6, the reaction solution in the reaction solution tank 4 flows into the battery reactor 3 through the first liquid outlet pipe 5, the water pump 6 and the second liquid outlet pipe 7 in sequence, and reacts The liquid reacts in the battery reactor 3, and in the process of the chemical reaction, heat must be released, and the temperature of the reaction liquid in the battery reactor 3 rises, wherein the battery reactor 3 is arranged above the reaction liquid tank 4;

[0056] Under the action of gravity, the reaction liquid in the battery reactor 3 is led back to the reaction liquid tank 4 through the flat liquid return pipe 1;

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com