A switched reluctance motor controller mainboard radiator for a novel angle grinder and the angle grinder

A technology of switched reluctance motor and angle grinder, applied in AC motor control, control system, grinder and other directions, can solve the problems of circuit board burning, loss of power electronic devices, etc. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

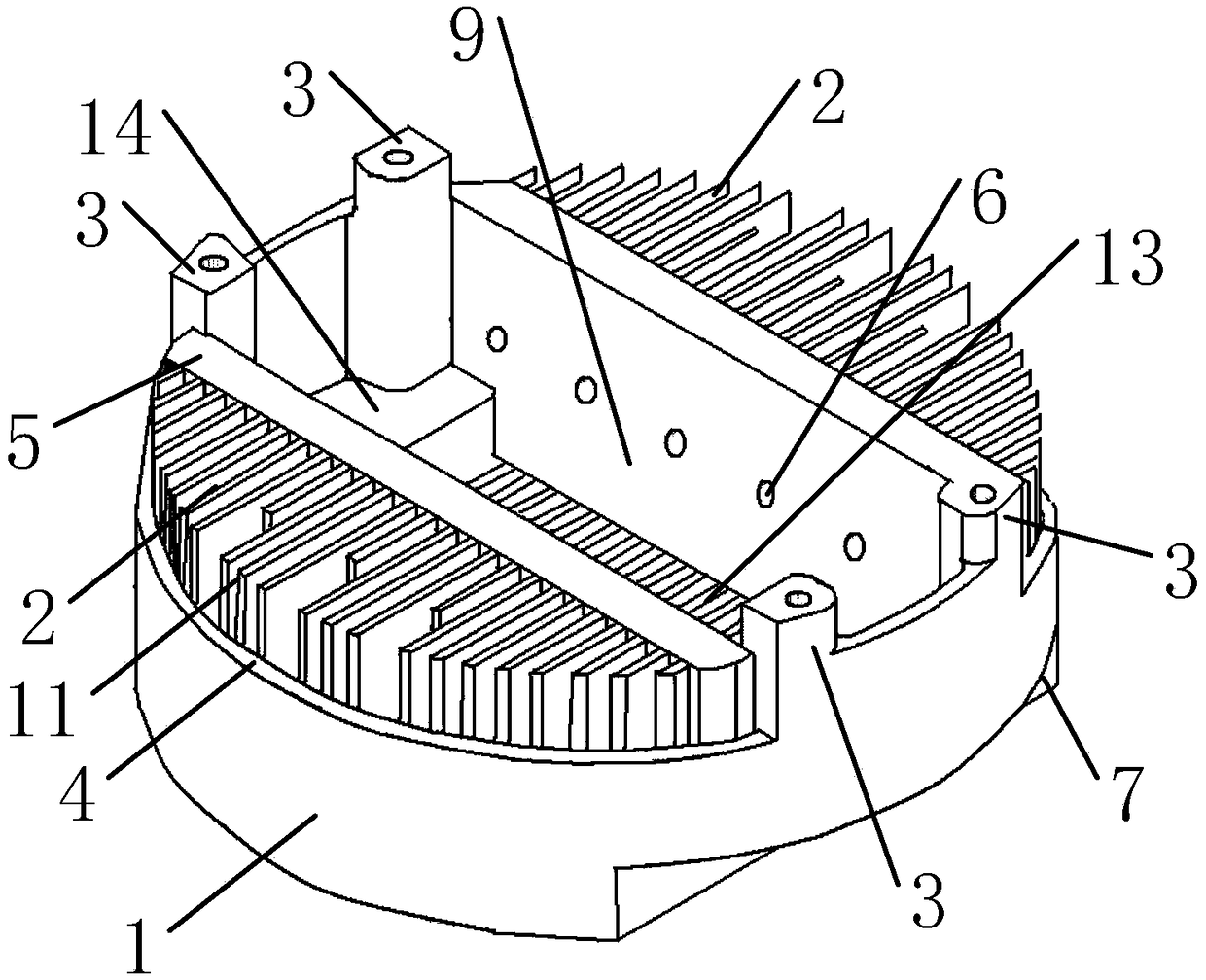

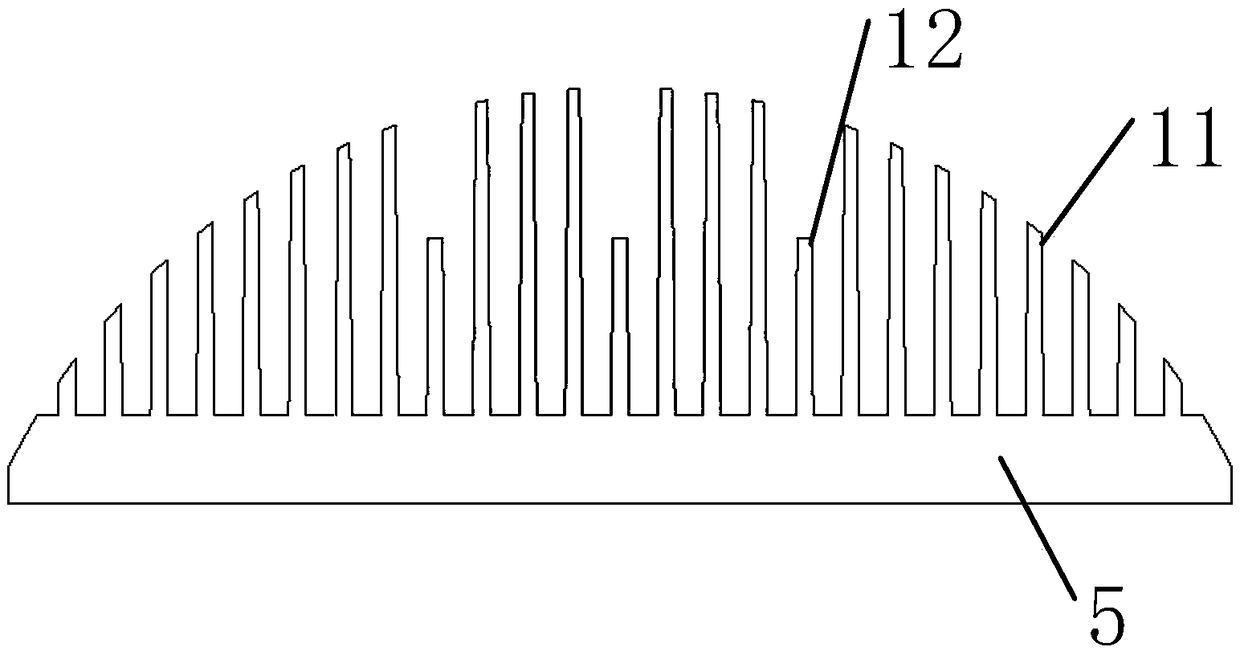

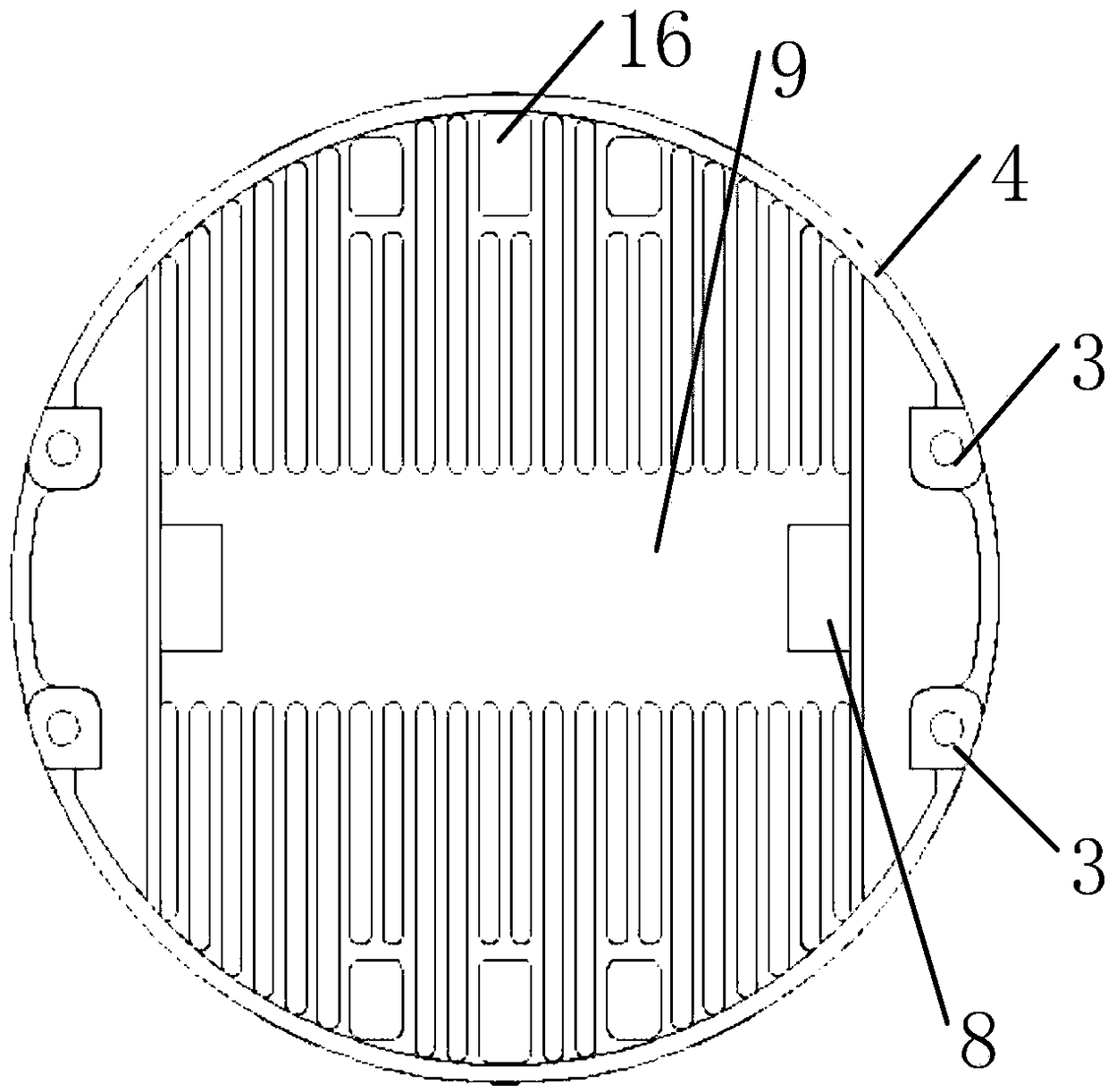

[0035] The present invention provides a novel angle grinder with switched reluctance motor controller motherboard radiator, such as Figures 1 to 3 As shown, it includes: heat dissipation body 1, heat dissipation body 1 is provided with motherboard placement groove 9; the two sides of motherboard placement groove 9 are respectively provided with heat dissipation mechanism placement groove 2; inside the heat dissipation mechanism placement groove is provided with several pieces of heat sink 11; motherboard placement A common groove wall 5 is provided between the groove 9 and the cooling mechanism placement groove 2, and a main board placement hole 6 is arranged on the common slot wall 5; It is located in the mainboard placement groove 9; the bottom of the mainboard placement groove 9 is provided with a heat sink 13 at the bottom of the mainboard placement groove; 13 The upper part, so that there is a space between the switched reluctance motor controller main board placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com