Fermentation device for canned food preparation

A fermentation device and canned food technology, applied in the field of food processing, can solve the problems of inability to scale and industrialize kimchi, inability to guarantee food safety, difficult control of temperature and density, etc., so as to improve product quality, increase effective fermentation rate, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

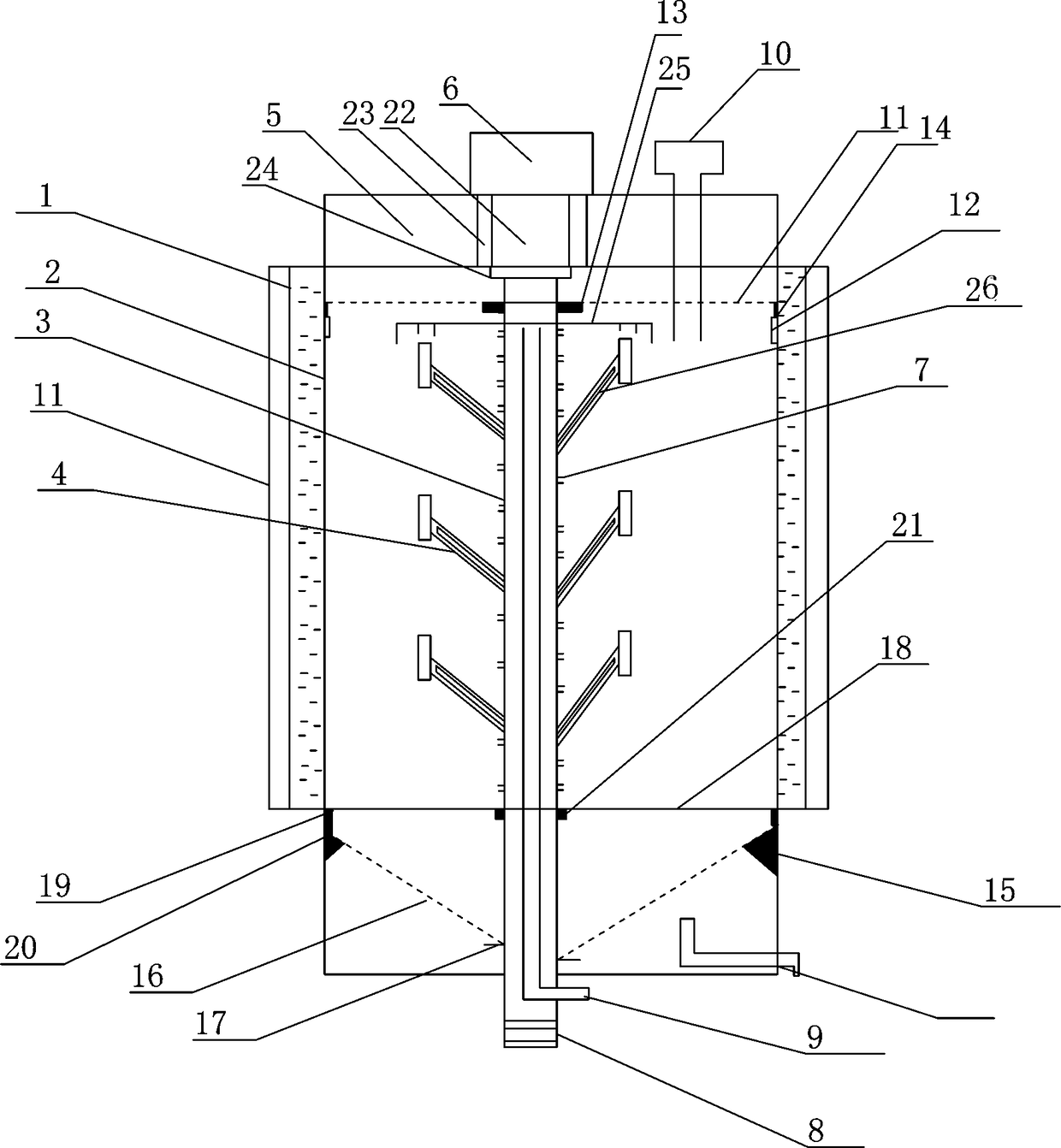

[0021] A fermentation device for canned food production, the device includes a tank body 1, an insulation tank 2 is arranged in the inner cavity of the tank body 1, and a gap is provided between the two, and the gap is filled with liquid, the top of the heat preservation tank 2 is provided with a tank mouth, and the heat preservation tank 2 is provided with a top cover 5 to form a sealed tank. The top cover 5 is provided with a motor 6, and the heating tank 2 A stirring shaft 3 is arranged in the inner cavity of the stirring shaft 3, and a stirring blade 4 is arranged on the stirring shaft 3, and the rotating shaft 26 of the motor 6 passes through the top cover 5 and is driven and connected with the stirring shaft 3, and the shaft center of the stirring shaft 3 There is a through hole, and on both sides of the stirring shaft 3 in the insulation tank 2, there are vent holes 7 evenly arranged at intervals, and the end of the stirring shaft 3 extends through the tank body 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com