High-pressure mold storage system

A storage system and mold technology, used in mold auxiliary parts, manufacturing tools, ceramic molding machines, etc., can solve problems such as stomata blockage, drainage, and bad, and achieve the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

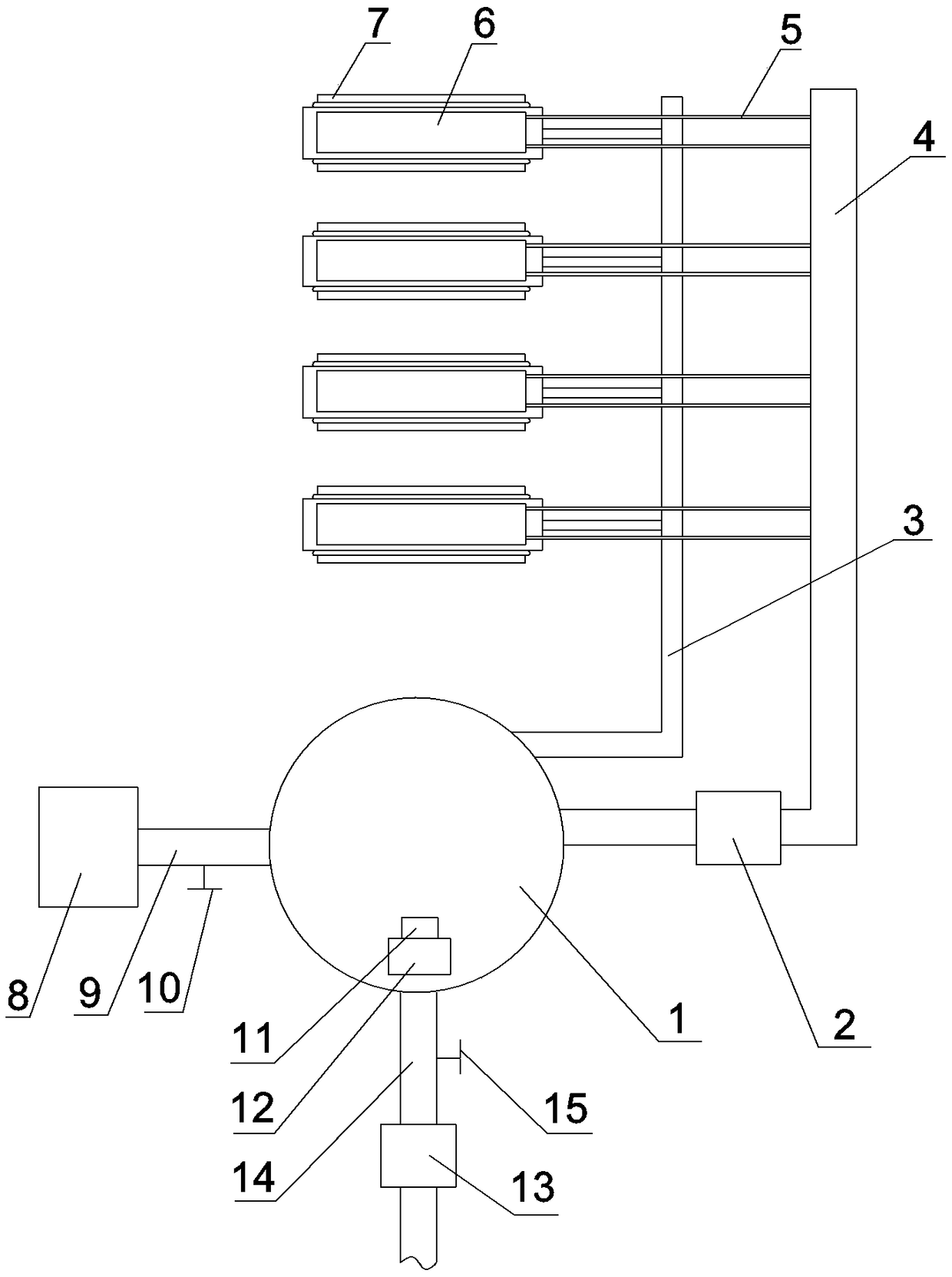

[0034] The embodiment is basically as attached figure 1 Shown:

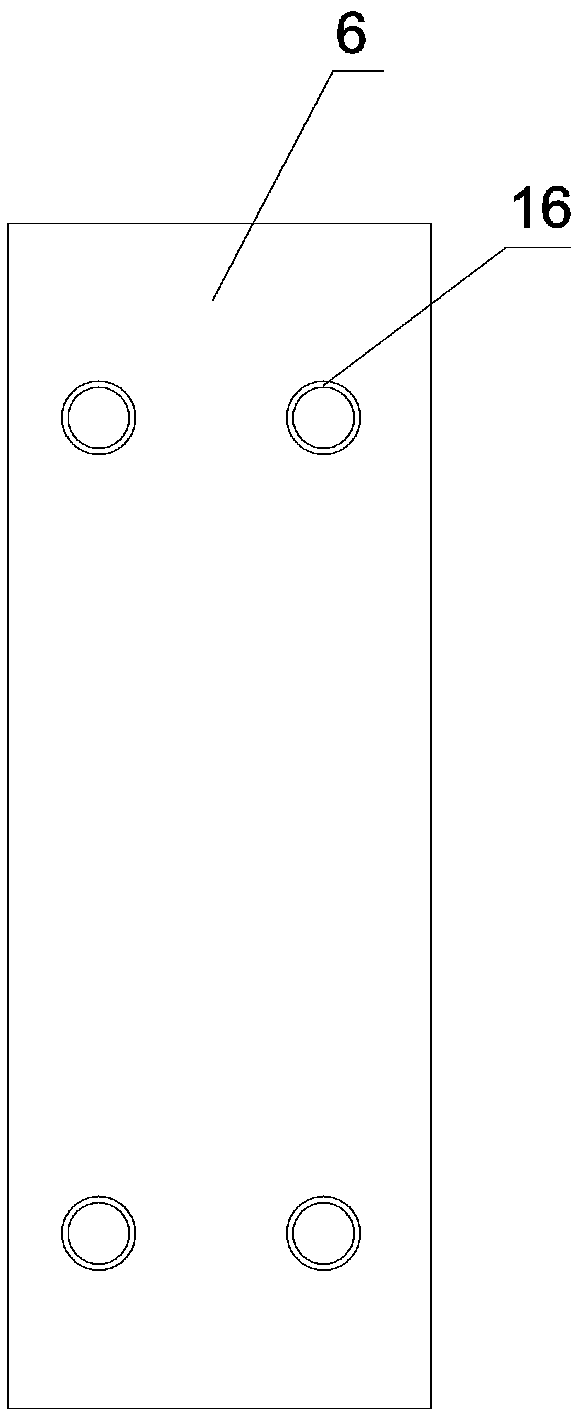

[0035] The high-pressure mold storage system of this embodiment includes a pool 1 for containing hypochlorous acid solution and a plurality of liquid pans 7 on which molds 6 are placed, and a liquid level sensor for detecting the liquid level of the pool is provided in the pool 1. In the example, the liquid level sensor adopts "Xingyi CYW11 Universal Input Transmitter". The liquid level sensor is electrically connected to the controller 11, and the model used by the controller 11 is AT89C51. The pool 1 is connected with a water supply pipe 14, a hypochlorous acid solution replenishing pipe 9 and a density detector 12 for detecting the density of the hypochlorous acid solution in the pool. Constant temperature type essential oil relative density concentration tester QL-120LE", the water supply pipe 14 is externally connected to the tap water pipe, the water supply pipe 14 is provided with a water supply valve 15,...

Embodiment 2

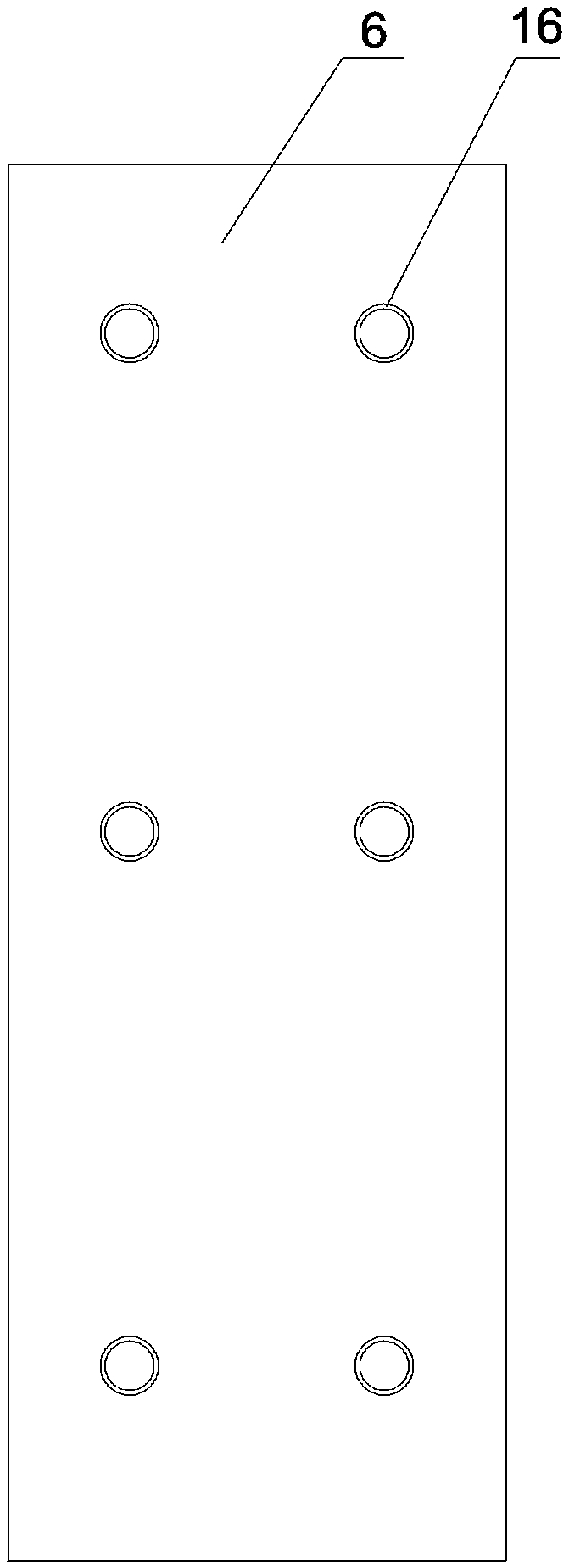

[0045] The difference between this embodiment and Embodiment 1 is that: image 3 As shown, the number of 16 female headers on the end face of the mold 6 is different. When the size of the mold 6 is large, the number of the 16 female headers on the end face of the mold 6 is set to six, and the six female headers 16 are arranged in two rows. Each row includes three. For the mold 6 with six female headers 16 on the end face, first connect the distribution distribution pipe 5 with the two female headers 16 located above, then install a male header 17 on both ends of a plugging pipe, and then install the sealing The two ends of the plugging pipe are respectively connected with the two female headers 16 located in the middle on the end face of the mold 6, so as to realize the blocking of the two female headers 16 in the middle. The plugging pipe can prevent the hypochlorous acid solution entering the upper part of the mold 6 from being discharged from the two female heads 16 in the...

Embodiment 3

[0047] The difference between the present embodiment and the second embodiment is that the structure of the push-in connector assembly is different. The push-in connector assembly of the present embodiment is obtained by improving the quick-connect assembly of the embodiment 1 and the embodiment 2. Its specific structure is as follows Figure 5 As shown, a plugging block 20 is integrally formed on the inner wall of the female head 16, and a frustum-shaped plugging hole is provided on the plugging block 20, and a conical plugging head 22 is arranged in the plugging hole. 22 cooperates with the plugging hole, and the plugging head 22 and the plugging block 20 are also connected by a plurality of springs 23; a fixing frame 18 is integrally formed in the male head 17, and a driving rod 19 is arranged on the fixing frame 18 to seal The plug 22 is provided with a straight hole 21 for the driving rod 19 to pass through, and the straight hole 21 does not go through the plug 22 . When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com