Anti-mildew and anti-bacterial environment-friendly coating

An environment-friendly and coating technology, applied in the field of coatings, can solve problems such as poor water resistance, mildew, and endless emergence of environmentally friendly coatings, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

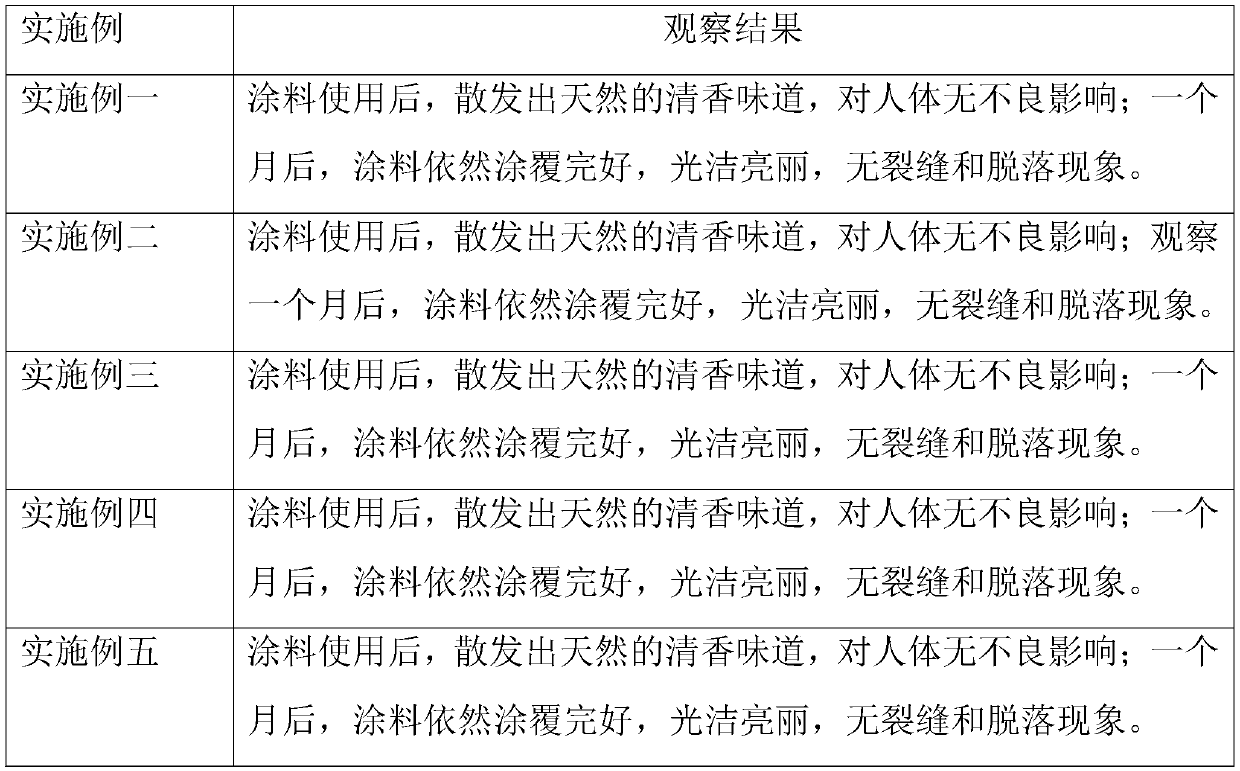

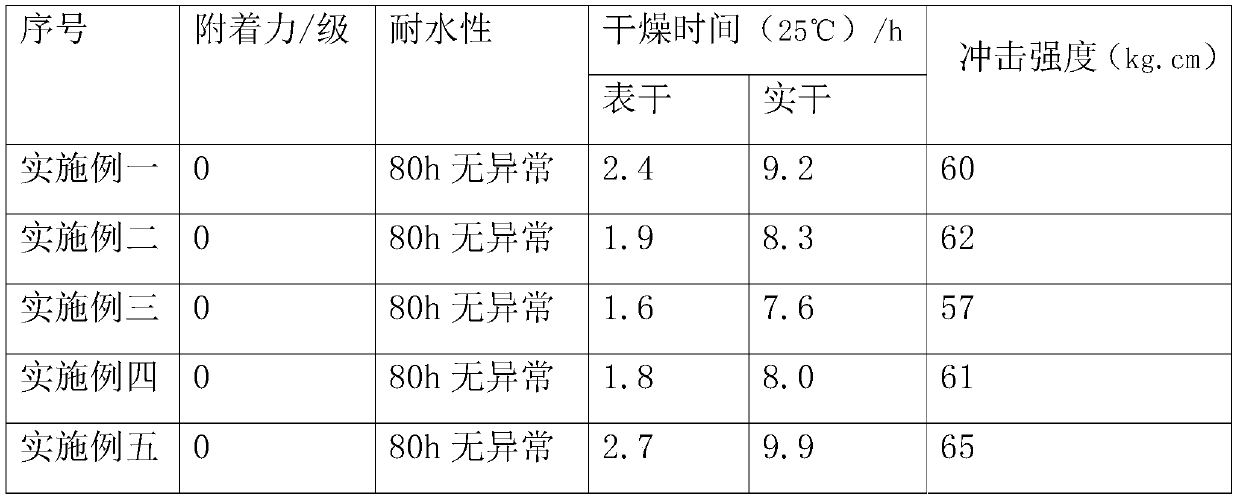

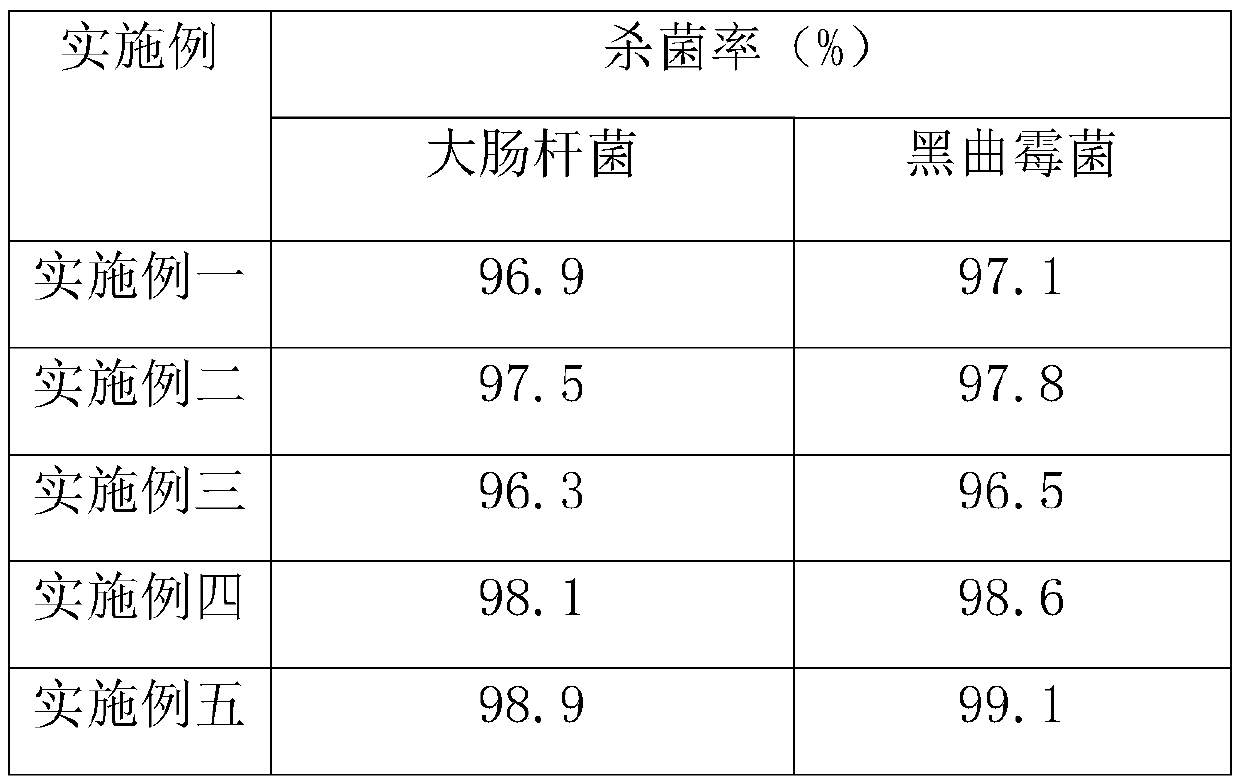

Examples

preparation example Construction

[0019] In the present embodiment, the preparation method of described coating comprises the following steps:

[0020] a. Grinding pyrophyllite and zinc oxide into fine powder, then uniformly mixing with nano-attapulgite, nano-kaolinite, shell powder, nano-titanium oxide, sepiolite powder and air-purifying sterilizing powder to prepare mixed powder;

[0021] b. Mix 2 / 3 volume of deionized water with polyvinyl alcohol, stir and heat up to 90°C. After the polyvinyl alcohol is completely dissolved, cool down to room temperature, add polyacrylate emulsion and epoxy resin, and heat at 300r / min Stir at least 45min at the stirring speed, then add polyacrylamide, mineral oil defoamer, polyacrylate ammonium salt dispersant, carboxymethyl cellulose, coconut oil, remaining deionized water and the mixture prepared in step a powder, and stirred at a stirring speed of 1000r / min for 10 hours; it is conducive to better dispersion of various raw materials, better compatibility, and better syner...

Embodiment 1

[0024]This embodiment provides a mildew-proof and sterilizing environment-friendly coating. The raw materials of the coating include the following components in parts by weight: 32 parts of polyvinyl alcohol, 15 parts of polyacrylate emulsion, 10 parts of nano-attapulgite, nano-kaolin 11 parts of stone, 10 parts of pyrophyllite, 12 parts of shell powder, 1.5 parts of zinc oxide, 0.8 parts of polyacrylamide, 8 parts of epoxy resin, 0.7 parts of mineral oil defoamer, 0.8 parts of nano-titanium oxide, 10 parts of air purification and sterilization powder , 5 parts of sepiolite powder, 0.2 part of polyacrylic acid ammonium salt dispersant, 0.2 part of carboxymethyl cellulose, 3 parts of coconut oil, 60 parts of deionized water;

[0025] The degassing and sterilizing powder is composed of dried wormwood, gardenia, lemon eucalyptus, apple eucalyptus and lemongrass in a mass ratio of 3:1:1:2:1 and then mixed.

[0026] In the present embodiment, the preparation method of described coa...

Embodiment 2

[0030] This embodiment provides a mildew-proof and sterilizing environment-friendly coating. The raw materials of the coating include the following components in parts by weight: 30 parts of polyvinyl alcohol, 16 parts of polyacrylate emulsion, 9 parts of nano-attapulgite, nano-kaolin 12 parts of stone, 9 parts of pyrophyllite, 14 parts of shell powder, 1.3 parts of zinc oxide, 0.9 parts of polyacrylamide, 7 parts of epoxy resin, 0.8 parts of mineral oil defoamer, 0.7 parts of nano-titanium oxide, 11 parts of air purification and sterilization powder , 4 parts of sepiolite powder, 0.2 part of polyacrylic acid ammonium salt dispersant, 0.2 part of carboxymethyl cellulose, 4 parts of coconut oil, 55 parts of deionized water;

[0031] The air-cleaning and sterilizing powder is composed of dried wormwood, gardenia, lemon eucalyptus, apple eucalyptus, and lemongrass in a mass ratio of 3:1:1:2:1 and then mixed;

[0032] In the present embodiment, the preparation method of described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com