Steam curing-free anti-corrosion concrete column and preparation method thereof

A technology of corrosion-resistant concrete and concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of high energy consumption of steam curing, adverse effects on concrete durability, and accelerated concrete hardening, so as to reduce the link of steam curing and economical Significant benefits and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

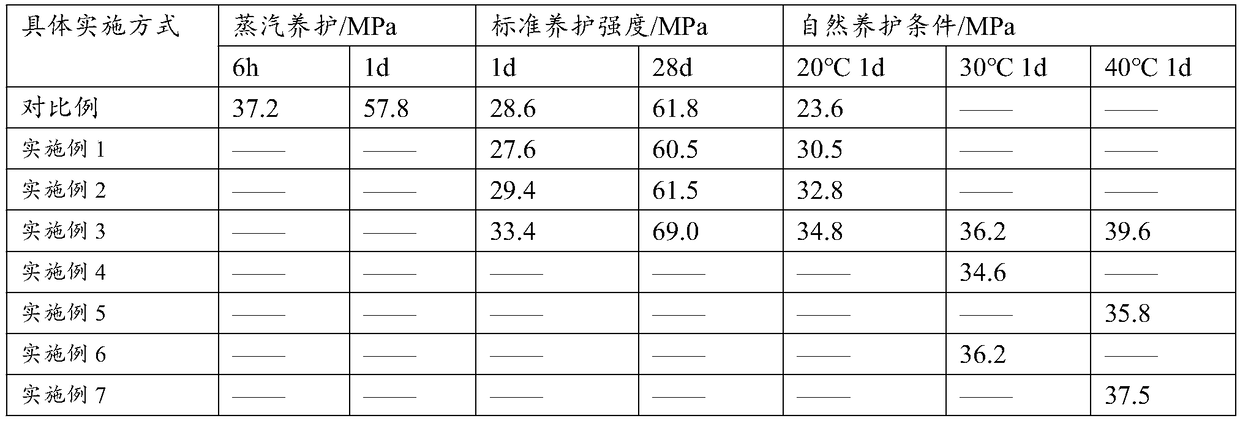

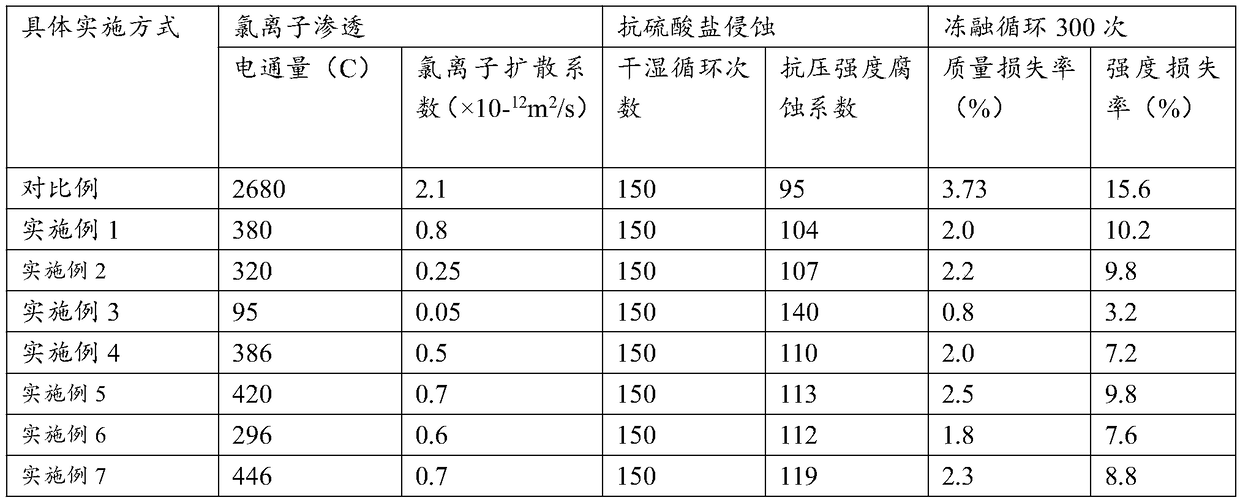

Embodiment 1

[0034] The concrete column provided by this embodiment is applied in a chloride salt environment and includes a column steel skeleton, concrete filled and wrapped around the steel skeleton and a waterproof coating, wherein the surface of the steel skeleton is covered with an evenly distributed anticorrosion layer. The column is prepared through the following steps:

[0035] (1) Preparation of steel skeleton

[0036] First, soak the steel bar surface with 3mol / L NaOH solution for 10min, then spray silane antirust agent on the surface, the initial spraying amount is 10g / cm 2 , and finally use the anti-rust steel bars to make the column skeleton structure, and put it into the mold that has been cleaned;

[0037] (2) Preparation of concrete

[0038] The concrete provided by the present embodiment comprises: early strength cementitious material, fine aggregate, coarse aggregate, water reducer, non-chloride salt early strength agent, anticorrosion agent and water, and water cement...

Embodiment 2

[0046] The concrete column provided in this embodiment is applied in a sulfate environment and includes a column steel skeleton, concrete filled and wrapped around the steel skeleton, and a waterproof coating, wherein the surface of the steel skeleton is covered with an evenly distributed anticorrosion layer. The column is prepared through the following steps:

[0047] (1) Preparation of steel skeleton

[0048] First, soak the steel bar surface with 3mol / L NaOH solution for 5 minutes, then spray silane antirust agent on the surface, and the initial spraying amount is 5g / cm 2 , and finally the steel bars after anti-rust treatment are made into column skeleton structures with different diameters and different lengths according to the design requirements, and put them into the cleaned mold;

[0049] (2) Preparation of concrete

[0050] The concrete provided by the present embodiment comprises: early strength cementitious material, fine aggregate, coarse aggregate, water reducer...

Embodiment 3

[0057] Present embodiment is except using nano-silicon substitution rate part silica fume, other conditions and parameters are all identical with embodiment 1, and wherein the addition of nano-silicon is 1.0% of total early-strength cementitious material quality, i.e. 4.65kg / m 3 , and the sum of the added amount of nano silicon and silica fume is 37kg / m 3 ); where the curing temperature is 20°C, 30°C, 40°C, and the curing time is 24 hours respectively;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com