Catalytic cracking method and device combined with hydrotreating

A technology for hydrotreating and catalytic cracking, which is applied in hydrotreating process, treatment of hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve problems such as prolific production of gasoline with low olefin content and high octane number, etc., and improve the conversion depth. and selectivity, reduction of olefin content, effect of low olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

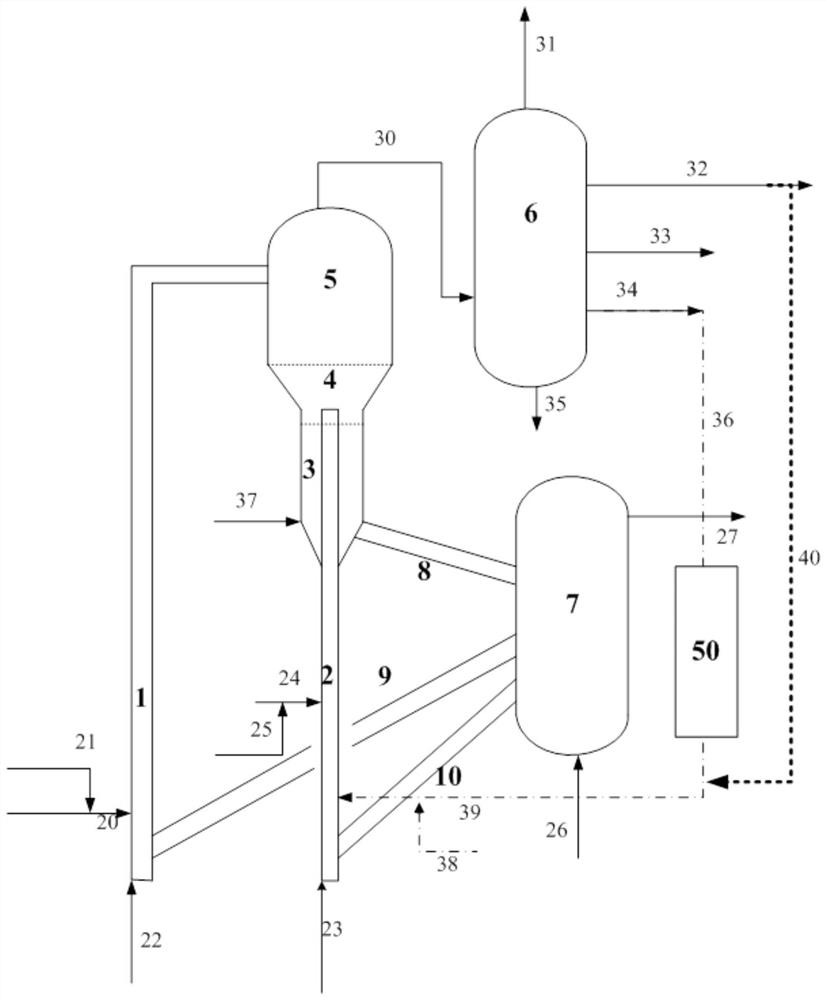

[0099] Embodiment 1 is carried out in medium-scale riser catalytic cracking unit, and adopts figure 1The process flow diagram shown is carried out, the internal diameter of the first riser reactor of this medium-sized device is 16 mm, and the height is 3800 mm, the internal diameter of the second riser reactor is 16 mm, and the height is 3200 mm, the second riser reactor The outlet is connected to the fluidized bed reactor. The inner diameter of the fluidized bed reactor is 64mm and the height is 600mm.

[0100] A stream of regenerated catalyst is introduced into the first riser reactor through the first regenerated inclined tube, and flows upward under the action of the pre-lift medium (steam); raw material B is preheated and mixed with atomized water vapor, and passed through the feed The nozzle enters the first riser reactor and contacts with the hot regenerated catalyst to carry out the catalytic conversion reaction. The reacted oil gas and catalyst mixture go up the first...

Embodiment 2

[0113] Carried out by a method similar to that of Example 1, except that the mixture ratio (A-2:C=1:3) of the hydrotreated cracked heavy oil fraction (raw material A-2) and the cracked gasoline fraction (raw material C) was changed, And the operating conditions of the combined reactor formed by the second riser reactor and the fluidized bed reactor, the main operating conditions and results of the experiment are listed in Table 3.

Embodiment 3

[0118] Carried out by a method similar to that of Example 1, only changing the ratio (A-2:C=1:2) of the mixture of hydrotreated cracked heavy oil fraction (raw material A-2) and cracked gasoline fraction (raw material C), As well as the relevant operating conditions, the main operating conditions and results of the experiments are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap