Manufacturing method of excavator counter weight

A manufacturing method and excavator technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of incomplete air-drying and curing, corrosion of counterweights, and different air-drying speeds, so as to shorten the air-drying and curing time and reduce the overall weight Effects of increase or decrease and increase in productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

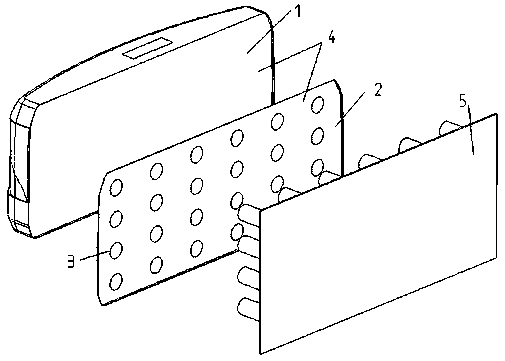

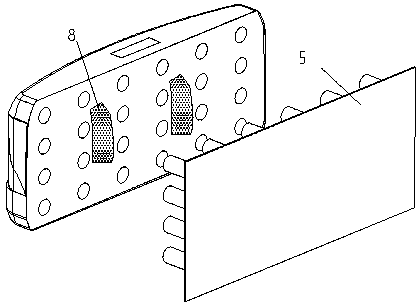

[0025] Example 1, such as Figure 1-5 As shown, this embodiment provides the specific process steps of the method for manufacturing the counterweight of the excavator.

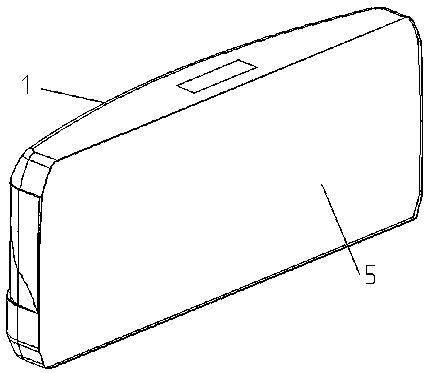

[0026] (1) Make a hollow counterweight skin 1 with a filling port and an open side. The filling port is located on the top of the counterweight skin 1 for filling the filler 8. The open surface of the counterweight skin 1 is on the top of the counterweight skin 1. For any side of the outer skin 1, the side with a larger cross-sectional area is generally selected as the open surface;

[0027] (2) Make the outer skin cover plate 2 suitable for the side opening of the counterweight outer skin 1, and a plurality of through holes 3 are arranged on the outer skin cover plate 2, and the outer skin cover plate 2 and the counterweight outer skin 1 are combined to form a counterweight concave mold 4 , can be combined by welding or bolting;

[0028] (3) Make a counterweight punch 5 that is compatible with the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com