Rapid aging method for catalytic gasoline particle catcher

A particle trap and rapid aging technology, applied in the direction of instruments, machine/structural component testing, measuring devices, etc., can solve the problems of high cost, long cycle, different exhaust atmosphere, etc., and achieve strong practicability and easy operation , the effect of short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

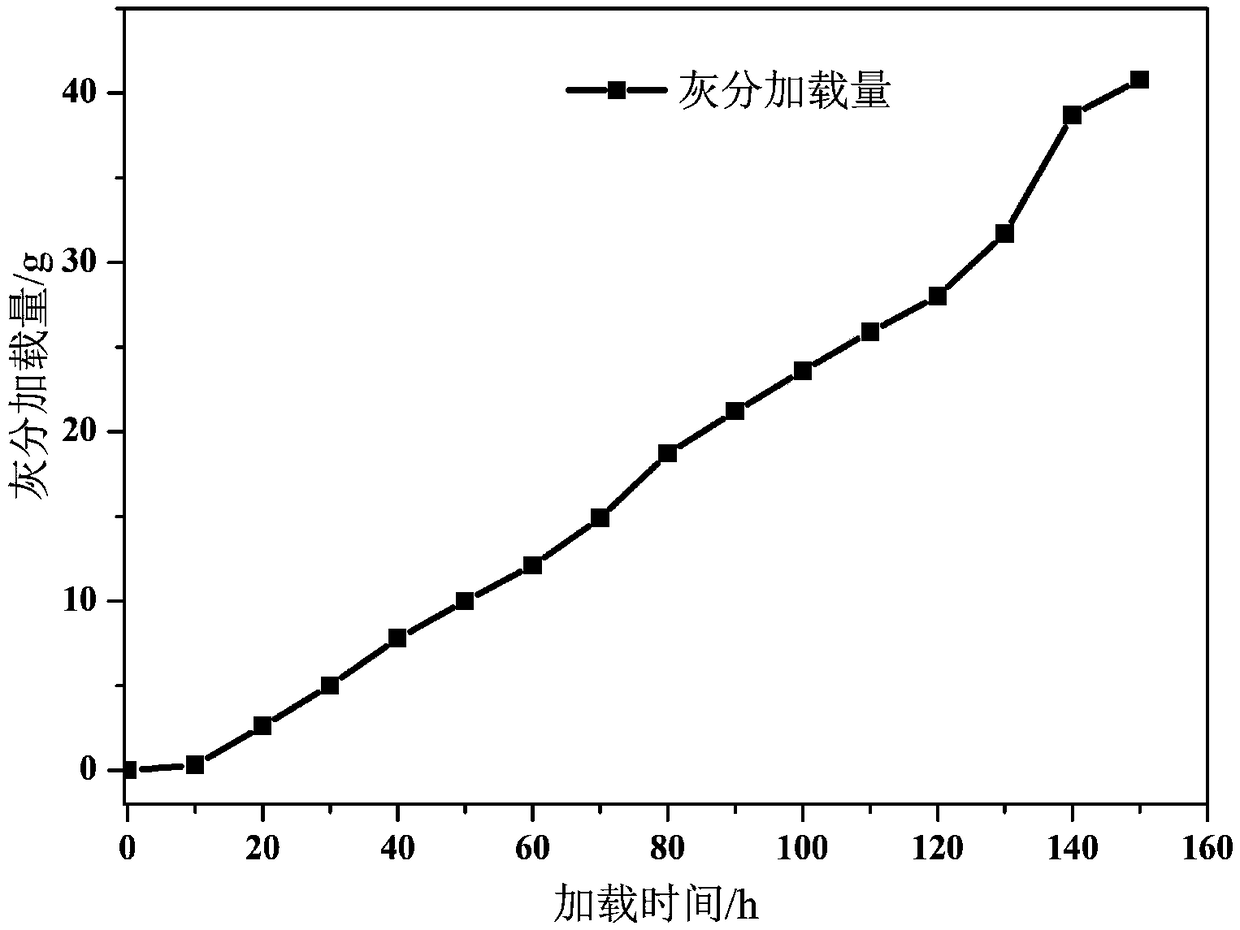

[0024] The carrier specification of the catalytic gasoline particulate filter used in this example is Φ118.4*152.4 (mm), the mesh number is 300cpsi, the wall thickness is 8mil, the volume is 1.68L, and its load is 75g / L catalyst coating, and the precious metal content is 8g / ft 3 . The example target ash load M t It is 42g, simulating the 200,000 endurance mileage of a real car.

[0025] The present invention comprises the following steps:

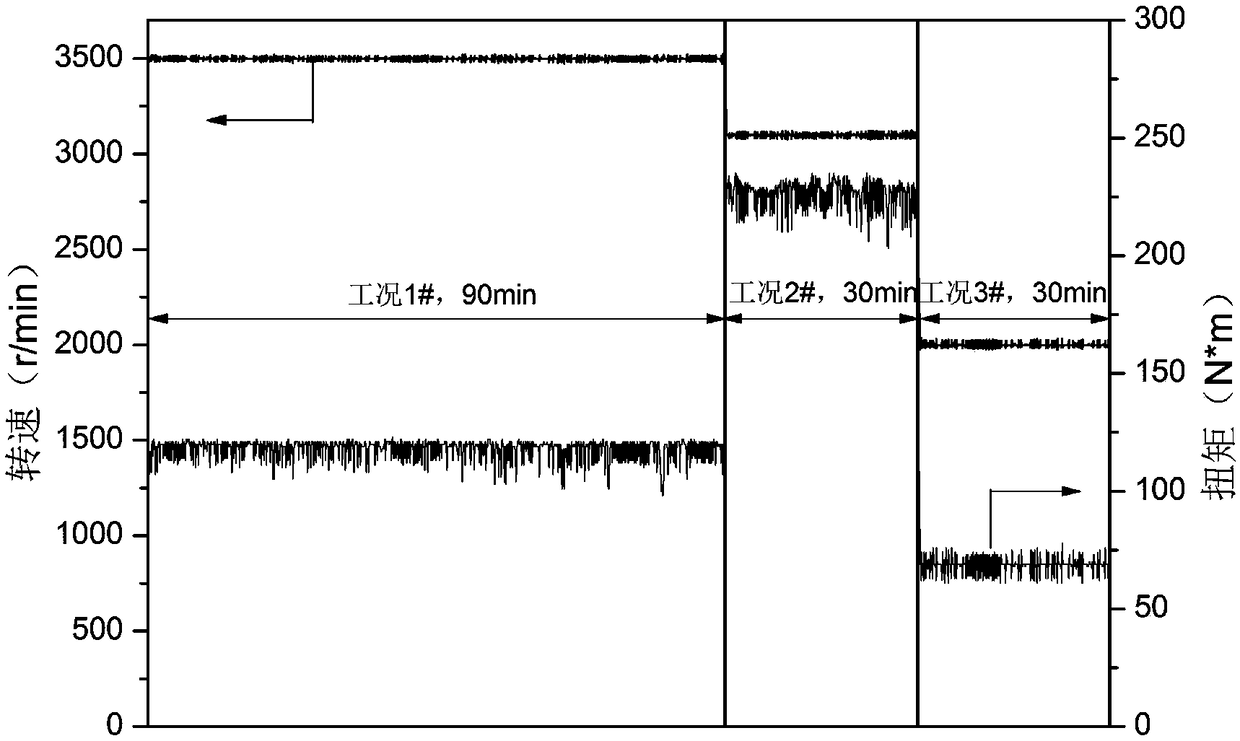

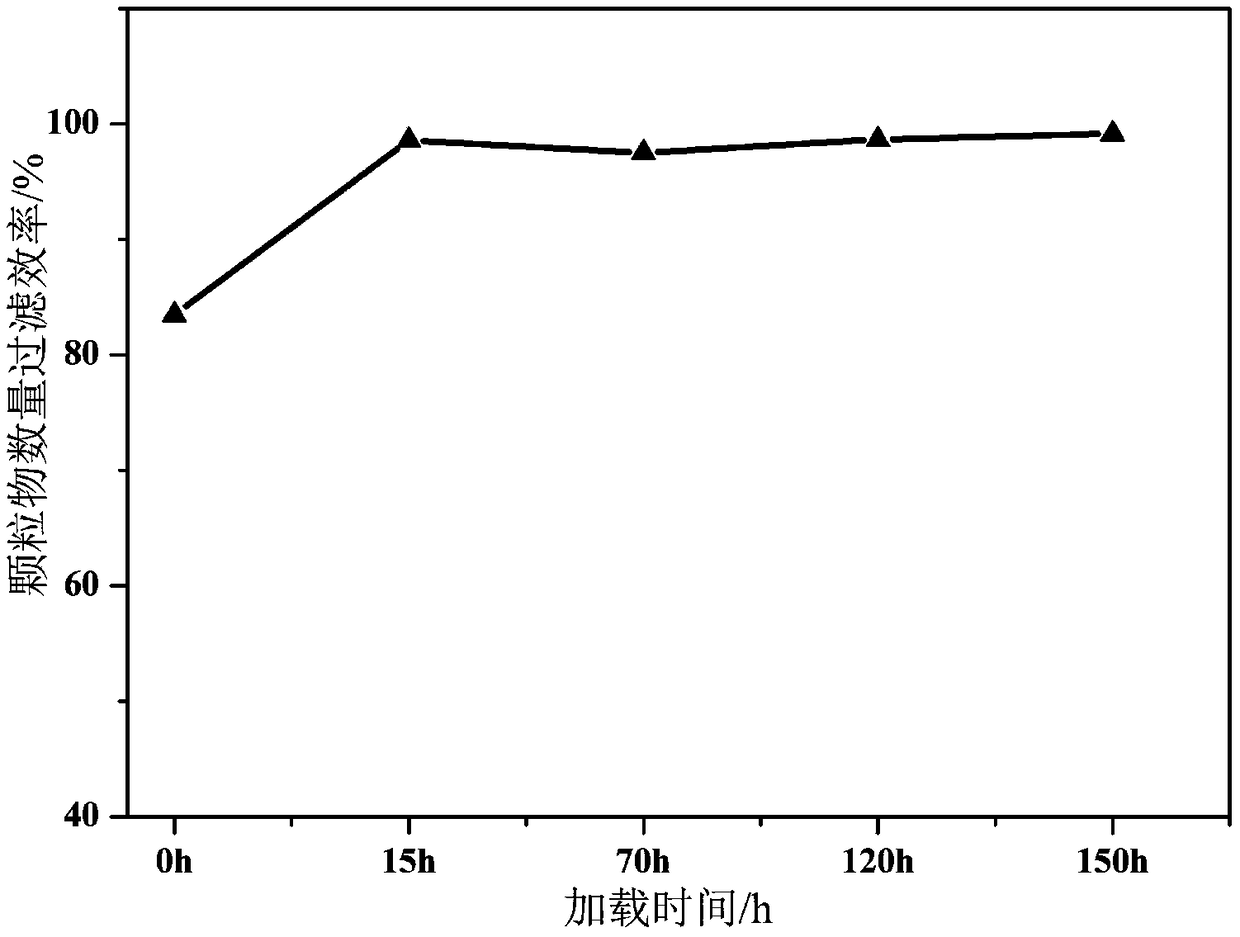

[0026] (1) According to the SRC test data of the 1.5L TGDI vehicle and the engine universal characteristics and emission test data obtained on the 2.0L TGDI engine bench; design three steady-state working conditions (denoted as working condition 1#, working condition 2 #, Working condition 3#) rapid aging, which is characterized by working condition 1# having high fuel consumption rate, working condition 2# having high fuel consumption rate and high exhaust temperature, working condition 3# having high particulate matter and smoke emiss...

Embodiment 2

[0035] The carrier specification of the catalytic gasoline particle filter used in this example is Φ118.4*152.4 (mm), the mesh number is 300cpsi, the wall thickness is 8mil, the volume is 1.68L, and its load is 100g / L catalyst coating, and the precious metal content is 8g / ft 3 . The example target ash load M t It is 33.6g, and the endurance mileage of a simulated real car is 160,000.

[0036] Include the following steps:

[0037] (1) The catalytic gasoline particulate filter is tested on a 1.5LTGDI vehicle, and the vehicle emission test results are used as the test comparison after aging;

[0038] (2) Aging the catalytic gasoline particulate filter after the vehicle test on the 2.0LTGDI engine bench, weighing the catalyst at 200°C before starting the aging, and determining the weight M before aging 0 . Then perform aging according to the selected rapid aging conditions. Rapid aging working condition is made up of three steady-state working conditions (i.e. working condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com