Leveling screw device and application method thereof

A flat-screw and leveling technology, which is applied in the field of live broadcast machines, can solve the problems of inaccurate leveling of the bottom surface, leaving many large clods, etc., and achieve the effect of good leveling effect, fast and accurate leveling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

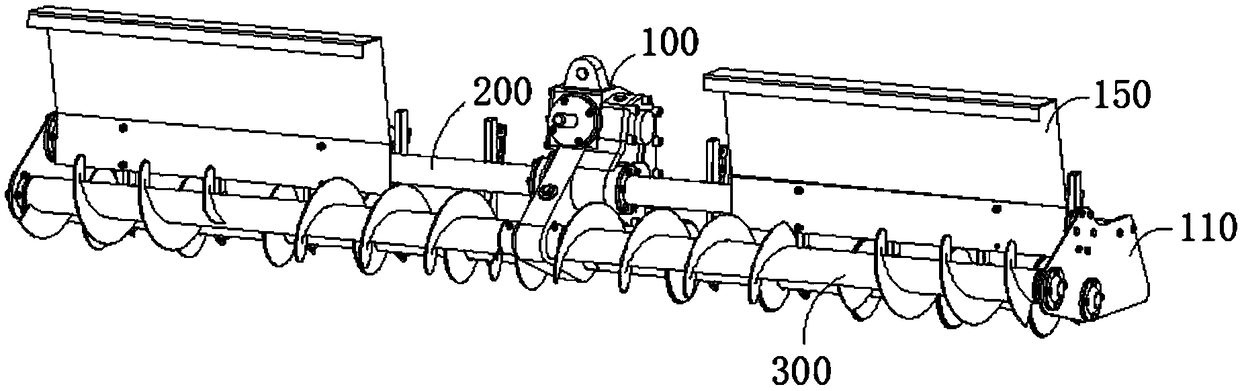

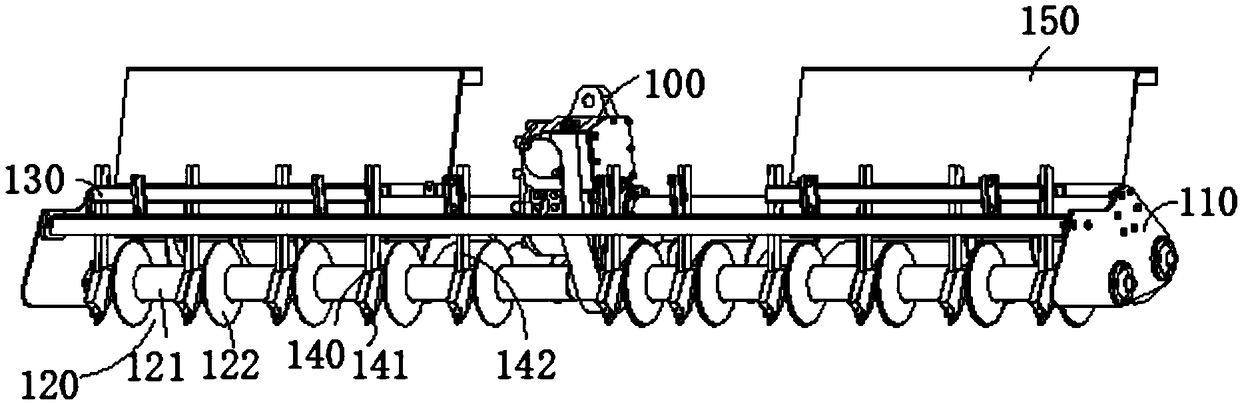

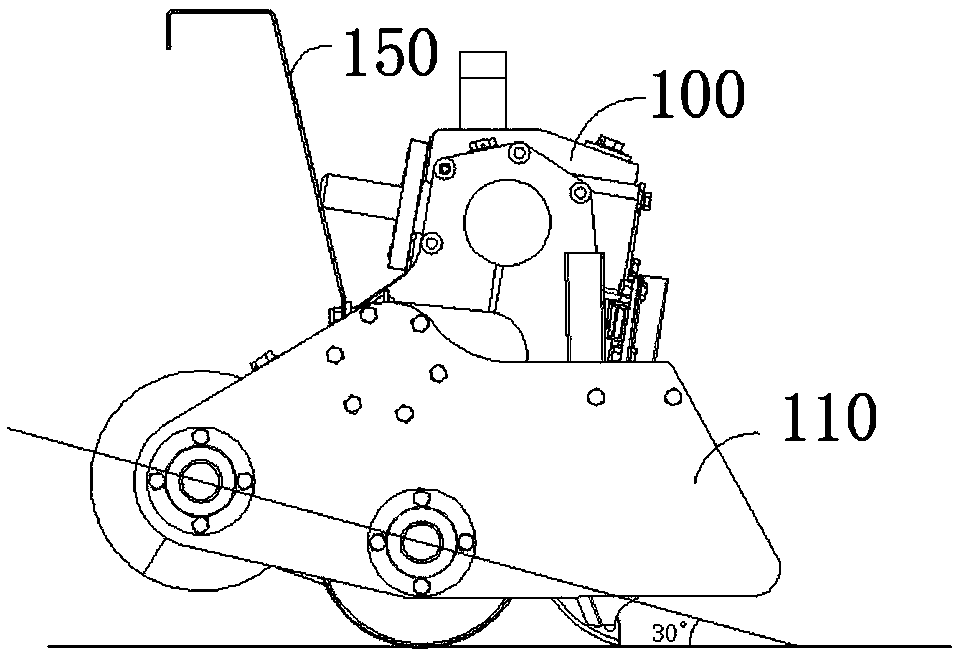

[0042] Refer to attached figure 1 , figure 2 , image 3 with Figure 4 As shown, a leveling screw device of this embodiment includes a transmission box assembly 100, a support tube 200 and a leveling screw 300, and the support tube 200 is located on both sides of the transmission box assembly 100 and is fixedly connected with the transmission box assembly 100 , the outer sides of both ends of the support pipe 200 are fixedly connected with side plates 110, a leveling screw 300 is arranged between the two side plates 110, the leveling screw 300 is connected with the transmission box assembly 100 gears, the central axis of the leveling screw 300 is connected The central axis of the tube 200 is parallel, the support tube 200 and the leveling screw 300 are symmetrical about the center plane of the transmission box assembly 100, and several fertilizer guiding tubes 142 are arranged between the two side plates 100. The unevenness of the bottom surface causes the seeder to bump d...

Embodiment 2

[0050] Refer to attached figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the use method of a leveling screw device in this embodiment is that the transmission box assembly 100 drives the leveling screw 300 and the fertilizer opener 120 to rotate, and the fertilizer guide pipe 142 transports the fertilizer to the knife 141 and the ditch that the ditching disc 122 opens.

[0051] The usage method of this embodiment includes the following steps:

[0052] S100, transmission, the transmission box assembly 100 drives the leveling screw 300 and the fertilizer opener 120 to rotate;

[0053] S200, leveling, the leveling screw 300 will level and unscrew the land required for operation;

[0054] S300, ditching, the ditching plate 122 and the scraper 141 break the land leveled by the leveling screw 300 to open the ditch;

[0055] S400, fertilization guide, the fertilization guide pipe 142 above the knife 141 transports the fertilizer to be applied to the ditch....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com