Marinating material for marinated procambarus clarkii and preparation method thereof

A technology for marinating Crayfish and Crayfish is applied in the processing field of braised products, which can solve the problems of inability to lock the moisture of shrimp meat, affecting the subsequent use of the marinade, and losing the value of products, so as to be beneficial to health and enhance immunity. Strength, rosy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

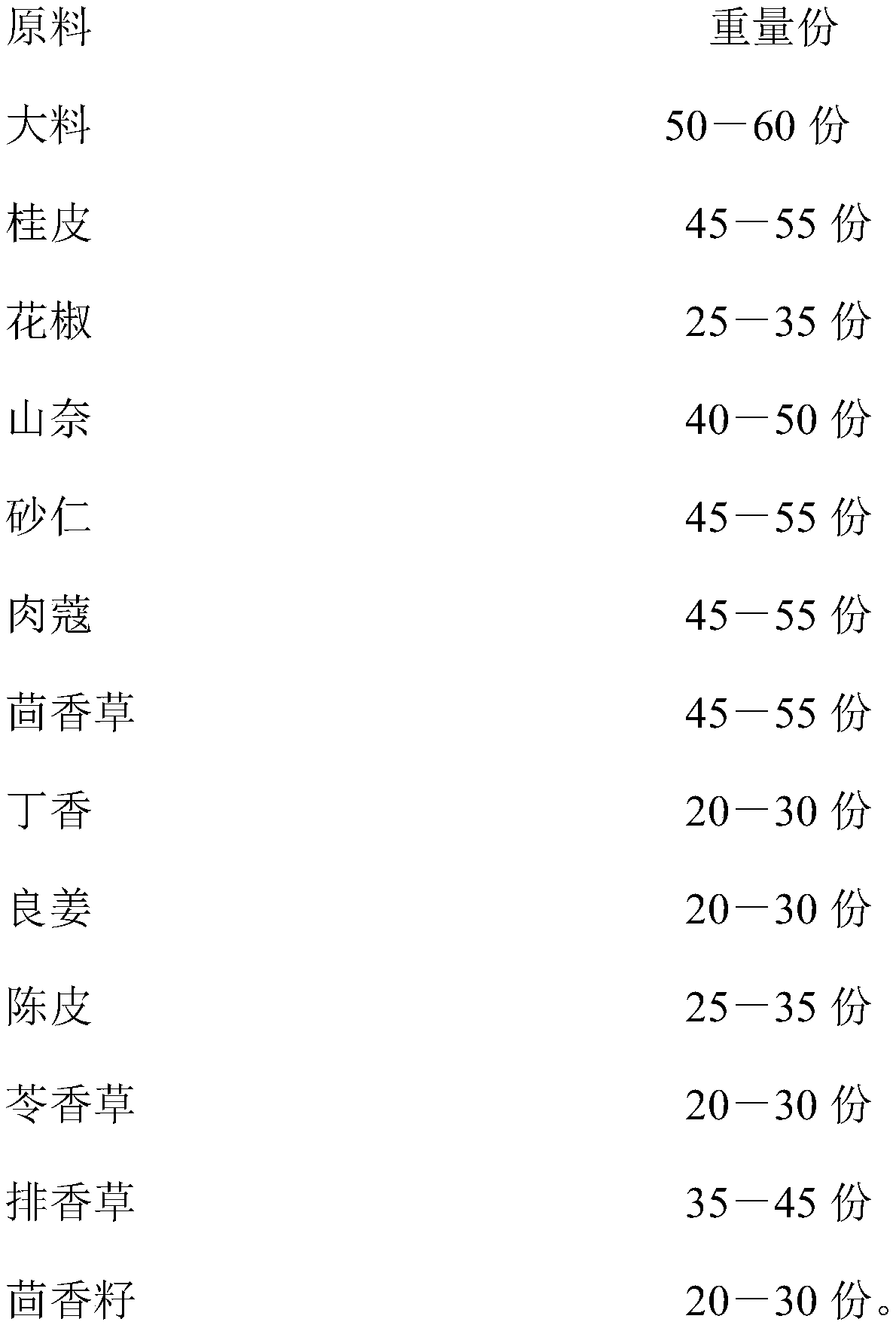

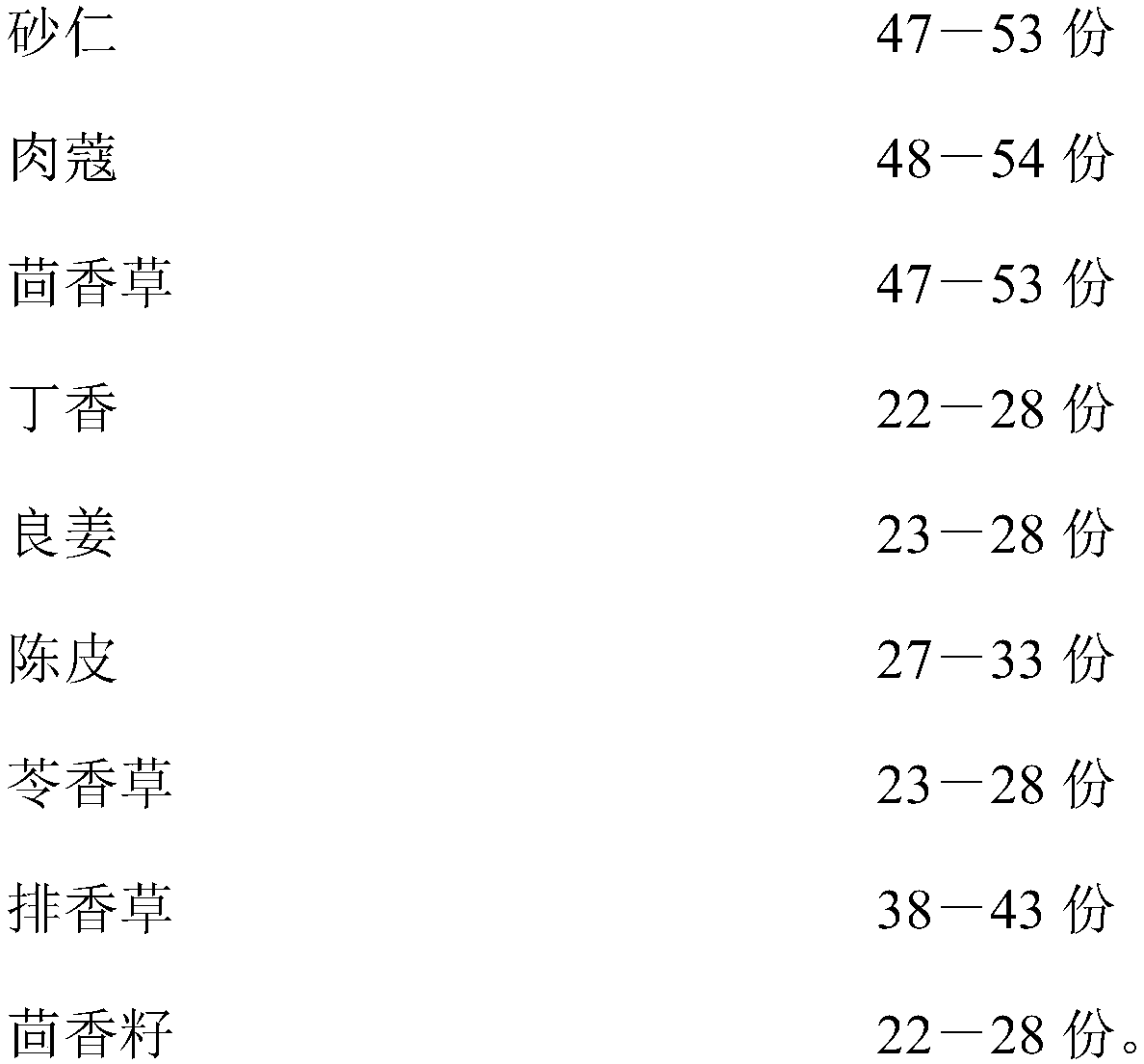

[0062] A marinated raw material for Procambarus clarkii, which is made from the following raw materials in parts by weight:

[0063]

[0064]

[0065] A method for marinating Procambarus clarkii using a marinade, the steps of which are:

[0066] A. Use 5.3Kg of fresh and live crayfish as raw material, wash and dry, first pass through boiling water (about 100°C), heat once for 3 minutes, and then remove the cooked shrimp to obtain cooked shrimp;

[0067] B, then heat the cooked shrimp in step A through stewed soup (soup made with 250g chicken or pork and stewed material) for a second time for 4 minutes, then remove the cooked shrimps after stewed;

[0068] C. Take out the cooked shrimps after stewing and put them into a vacuum packaging bag together with the marinade and vacuum seal;

[0069] D. Use the temperature-controlled boiling method to heat to 75°C for 5 minutes, then rapidly cool to 4°C;

[0070] E. Liquid nitrogen freezing: Use liquid nitrogen to freeze, so th...

Embodiment 2-7

[0074] The formula of embodiment 2-7 stewed Procambarus clarkii marinated material and crayfish is shown in the following table:

[0075]

[0076] The method of marinating Procambarus clarkii using the marinated material of the above-mentioned Examples 2-7 is the same as that of Example 1.

Embodiment 8

[0078] A method for marinating Procambarus clarkii using a marinade, the steps of which are:

[0079] A. On July 10, 2018, according to the ingredients, select 5kg Procambarus clarkii and 500g marinade.

[0080] B. Cooking: Pour 5kg of Procambarus clarkii into a boiling water pot, cook for 2 minutes, take it out, weigh it, and the weight is 4.7kg.

[0081] C. Cooking: Pour 4kg of water into the pot, after boiling, add auxiliary materials, cook for 15 minutes, pour the Procambarus clarkii into the pot, cook for 3 minutes and 30 seconds, remove and weigh, the weight is 4.4kg;

[0082] D, packaging sterilization: sub-package, 1kg of Procambarus clarkii in each packaging bag, pack the Procambarus clarkii and the marinade into a vacuum packaging bag, add 500 grams of marinade in each bag, and seal it after exhausting the air. High temperature sterilization, the sterilization temperature is 75 ℃, 5 minutes. It was then rapidly cooled to 4°C.

[0083] E. Liquid nitrogen freezing: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com