Fixing device for butt welding process of automobile u-shape coupling

A technology of fixing devices and couplings, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems of multi-size adjustable clamping, poor functionality, single clamping device structure, etc., and achieve welding gun skin The effect of regular pipeline routing, reasonable structural design, and enhanced flexibility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

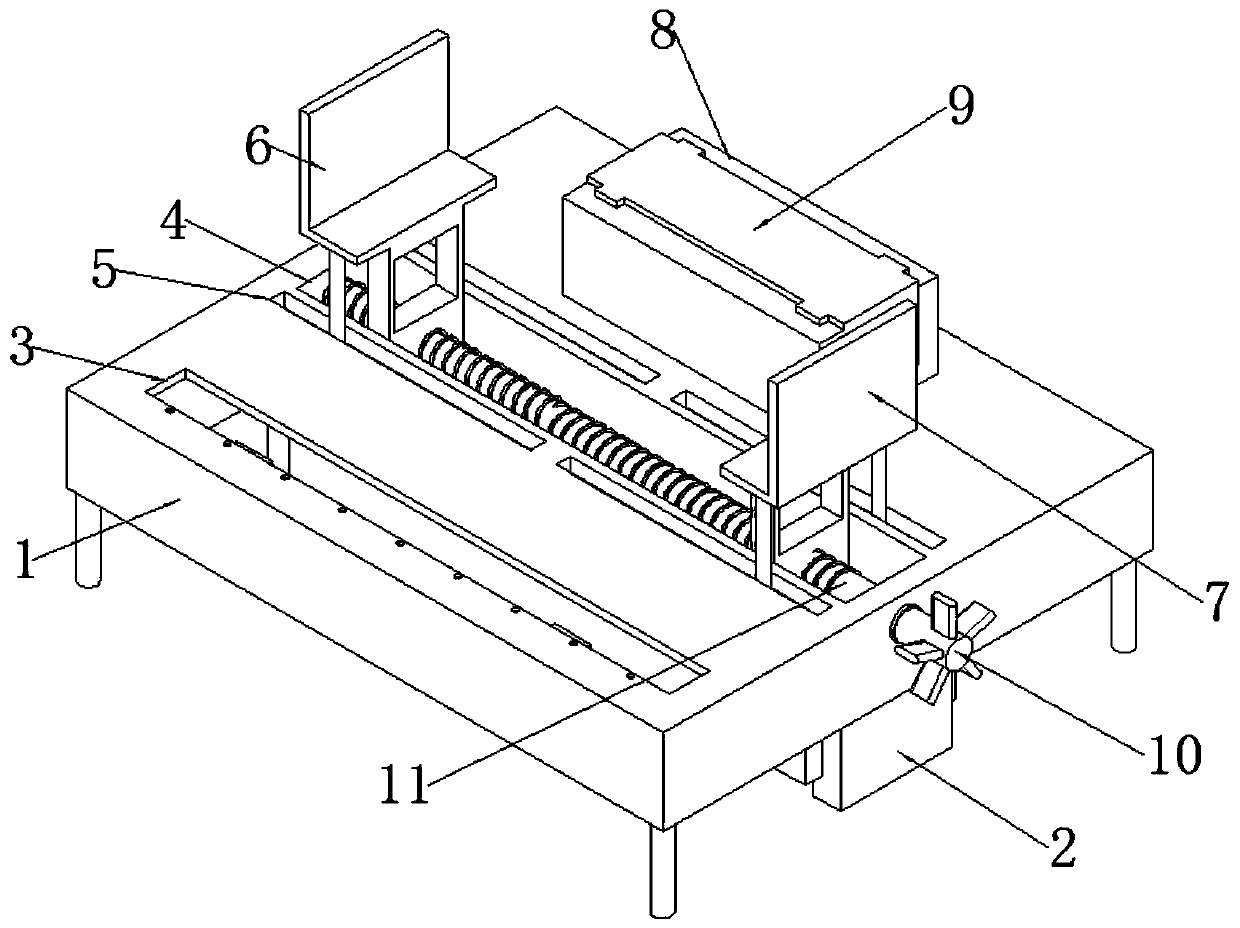

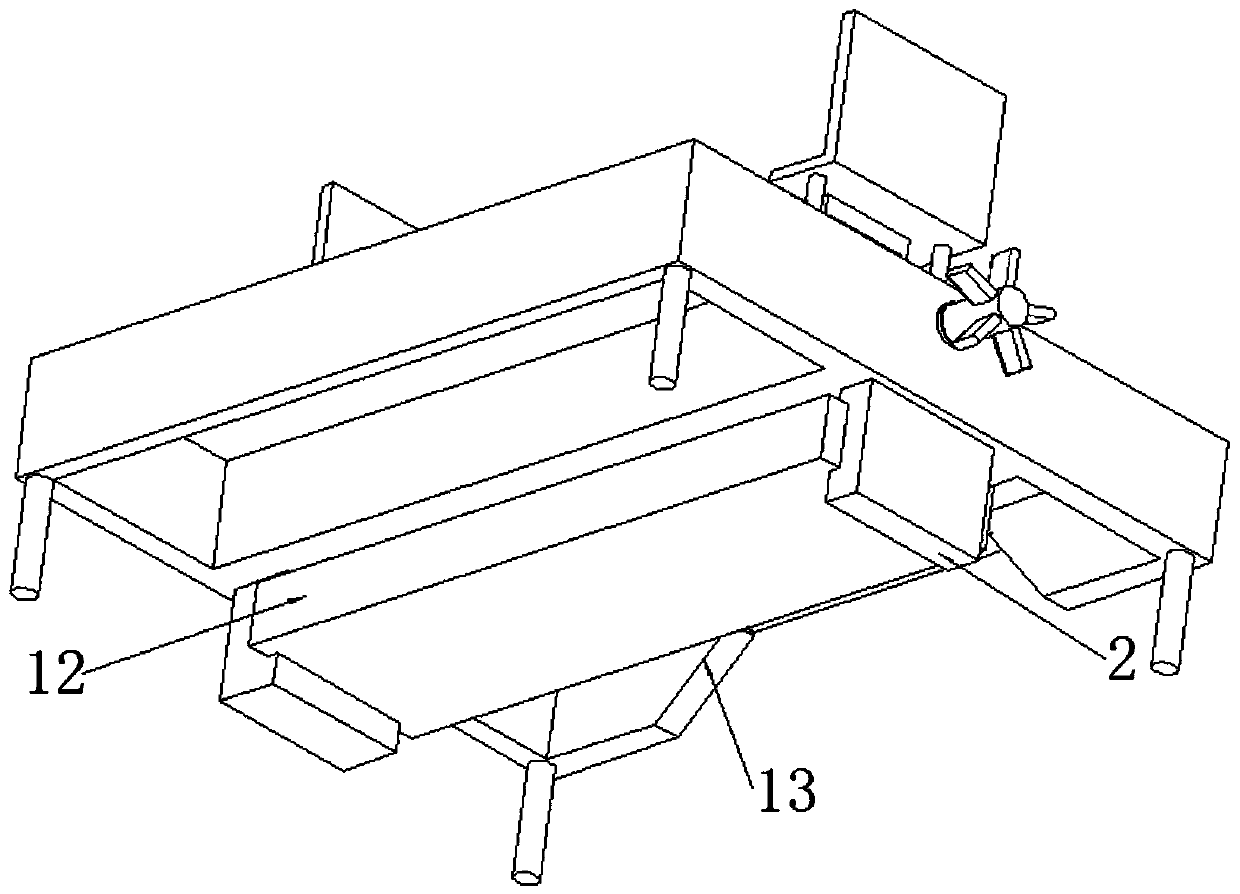

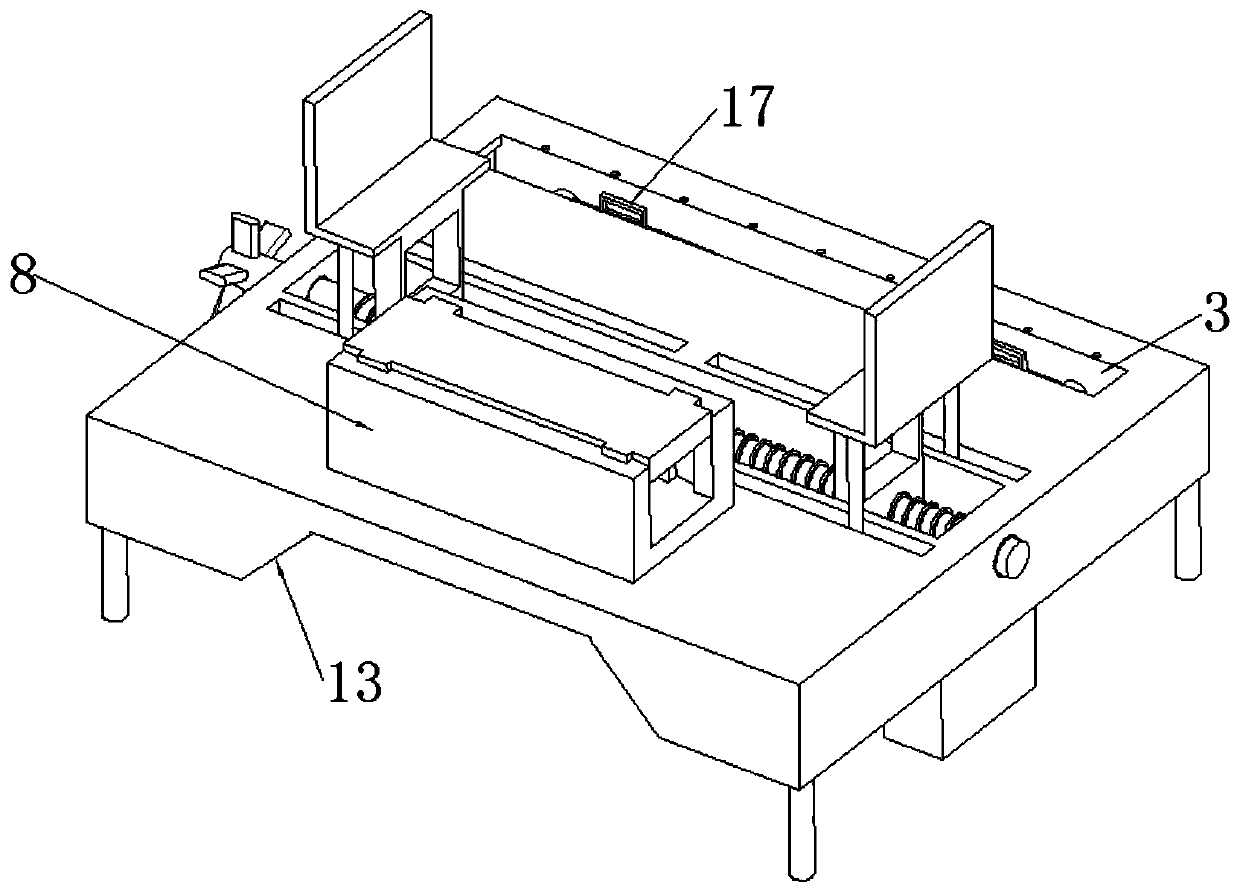

[0032] as attached figure 1 to attach Figure 9 Shown:

[0033] The invention provides a fixing device for butt welding of automobile U-shaped couplings, including: a fixing platform 1, a support frame 2, a functional groove 3, a screw fixing groove 4, a guide groove 5, a first clamping seat 6, and a second clamping seat 7. Functional seat 8, functional plate 9, runner 10, screw rod 11, slag hopper 12, hand groove 13, slag leakage hole 14, swivel seat 15, functional rod 16, handle 17, lever 18, threaded sleeve 19, Rotary rod 20, bearing seat 21 and limit plate 22; The bottom surface of described fixed platform 1 is supported by four columns, and two support frames 2 on the left and right are installed between the four columns, and at these two support frames 2 There is a slag receiving hopper 12 in the way of chute guide rails; the top front side of the fixed platform 1 is provided with a functional groove 3 and a screw fixing groove 4, wherein the screw fixing groove 4 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com