Supporting device for engine case machining

A technology for engine casings and support devices, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., to achieve the effects of improving manufacturing pass rate, reducing deformation problems, and solving effective support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

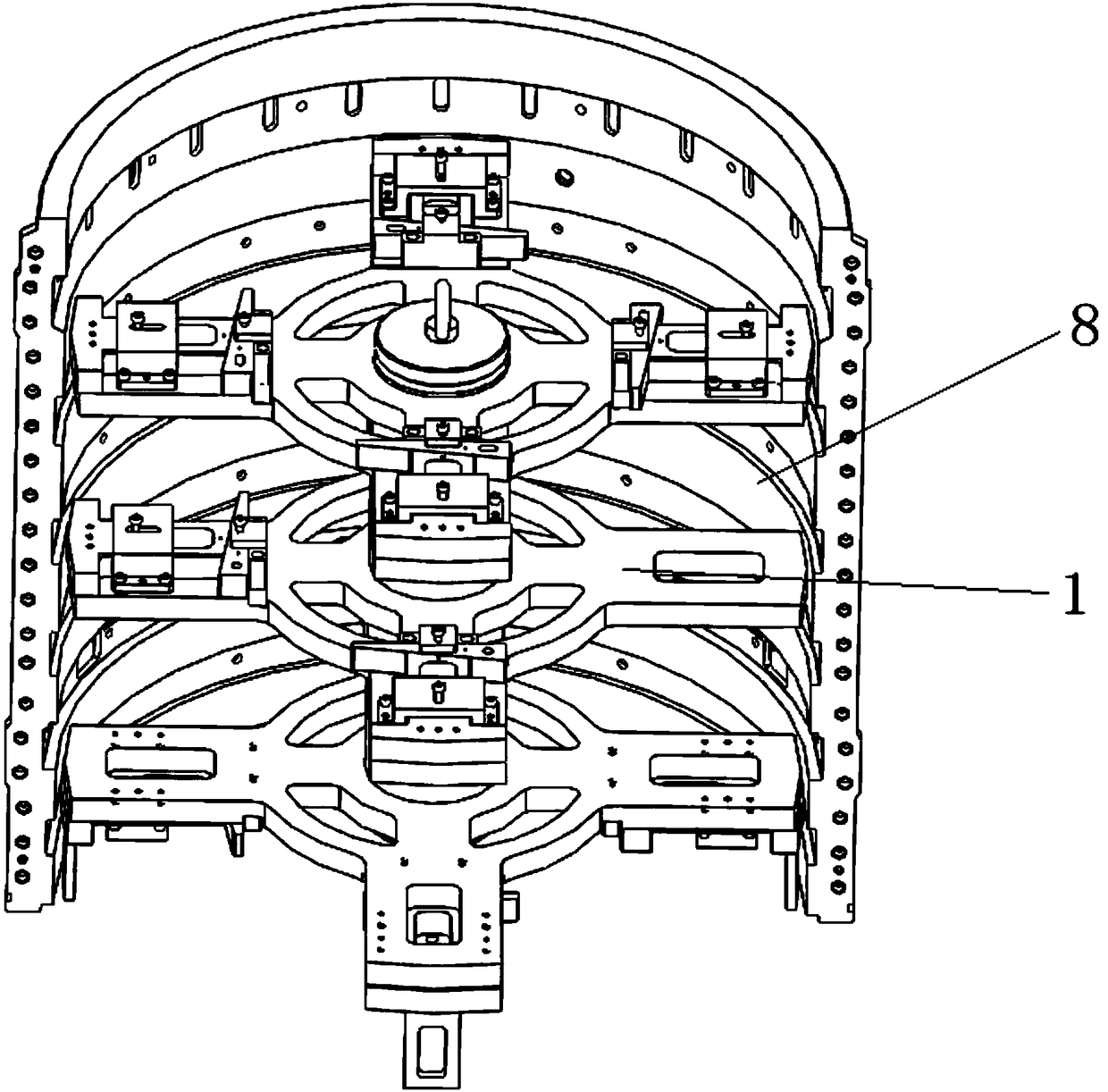

[0033] In this embodiment, the engine low-pressure casing is taken as an example. The casing 8 is a cylindrical shell, and the inner wall is provided with several stepped surfaces along the circumference. The material of the casing body is 1Cr12Ni3MoVN. 3Gr13, so that the entire supporting device expands as much as the casing 8 during welding and heat treatment, ensuring accurate, reliable and effective support.

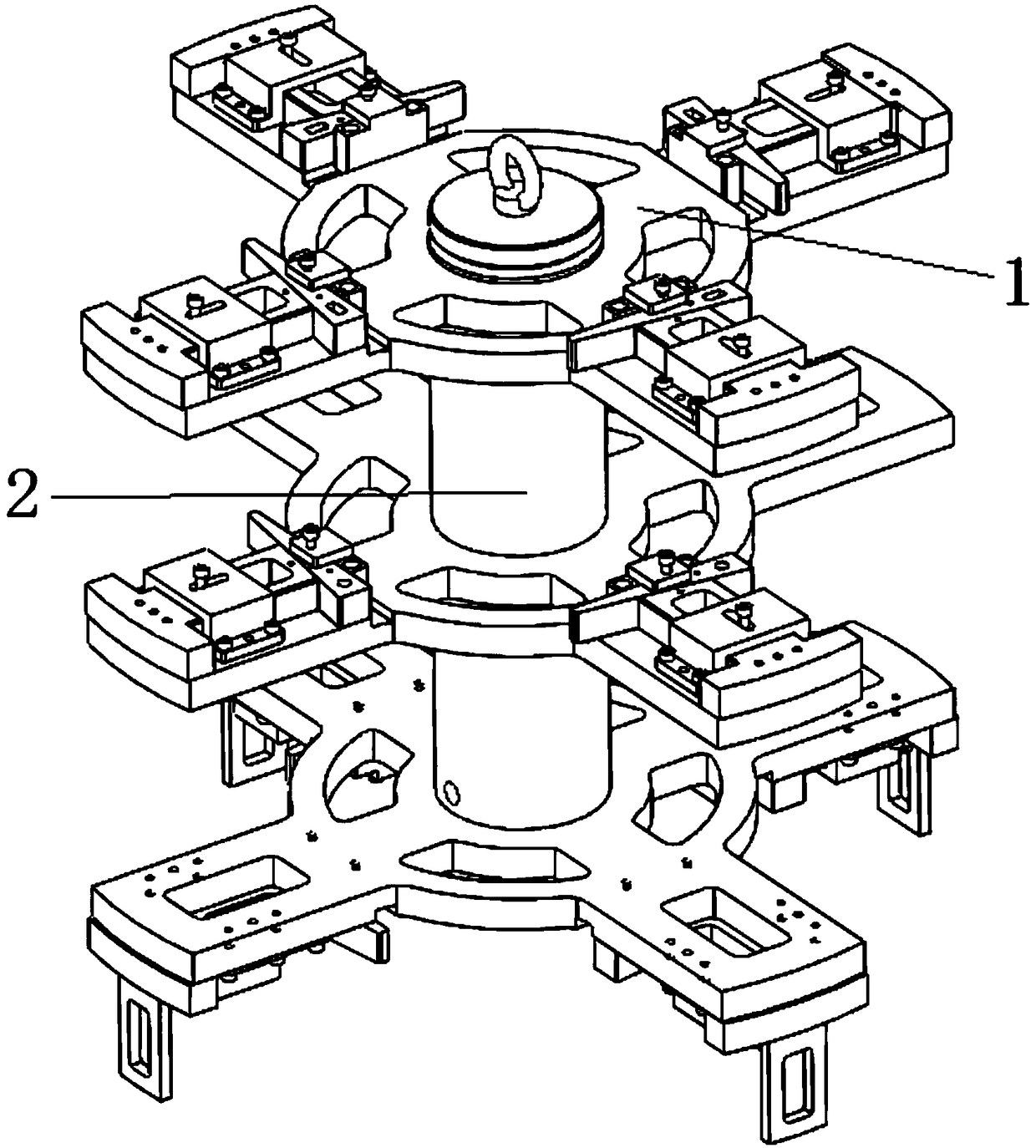

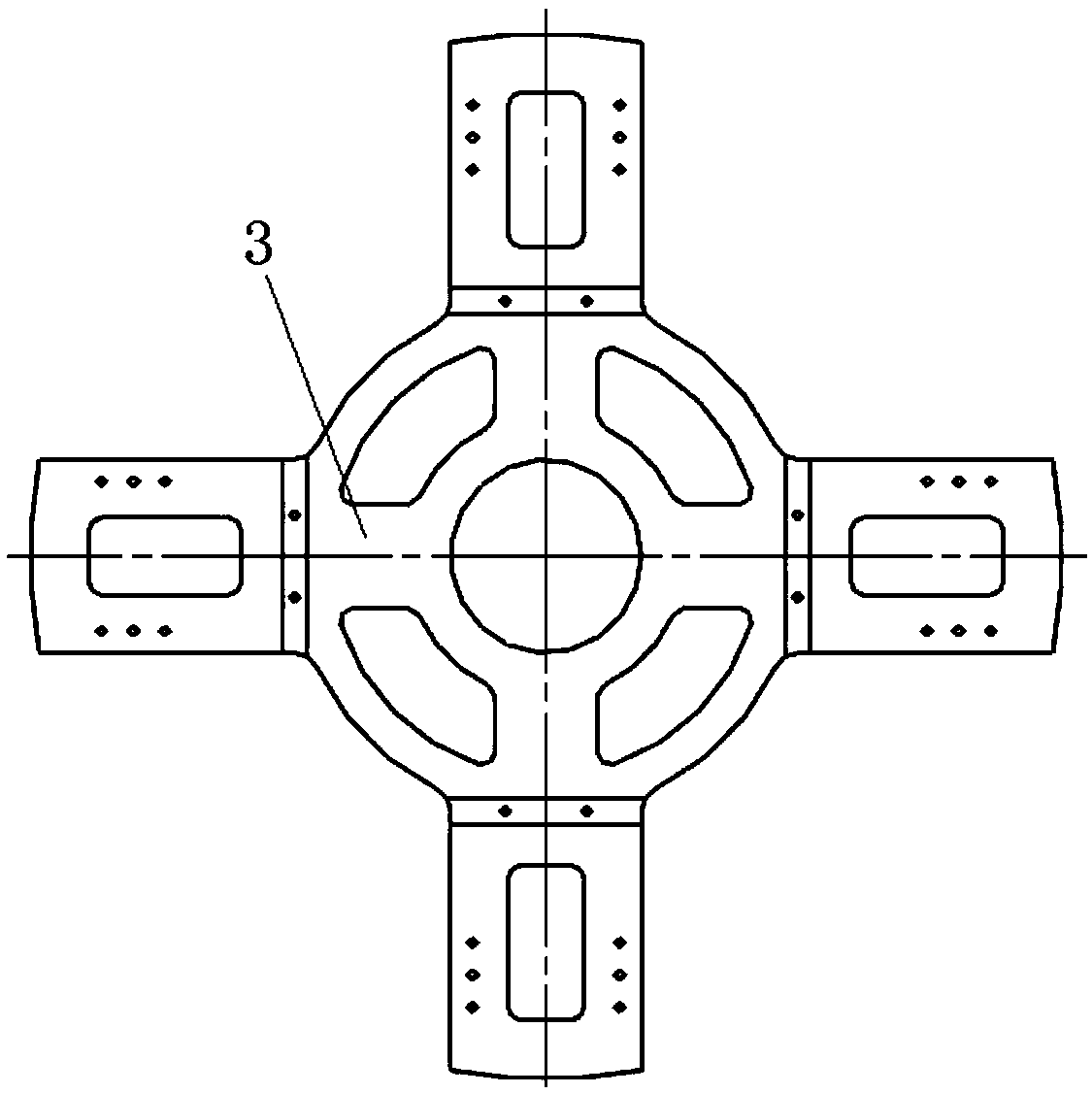

[0034] Such as figure 1 As shown, the supporting device is arranged inside the casing 8 to effectively support the casing 8 in the radial direction, including a pillar 2, at least one positioning plate 1 and an adjustment mechanism.

[0035] Such as figure 2 As shown, the pillar 2 is located at the center of the axis, and adopts a hollow cylindrical tube, and the two ends are welded with a cover plate, and a lifting nut is installed on the cover plate, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com