Continuous multi-station curved face polisher sand liquid circulating and protecting device

A protective device and polishing machine technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems that affect the processing accuracy and troublesome cleaning, and achieve improved recovery rate, reduced deposition, and high-efficiency sand liquid loop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

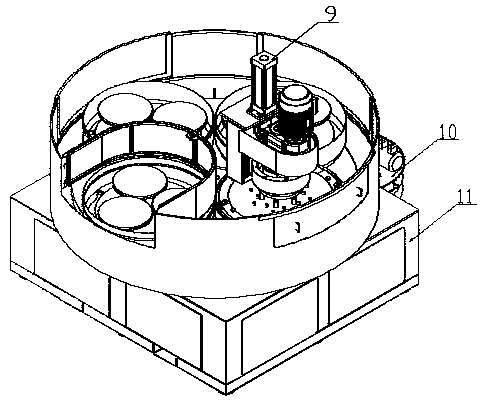

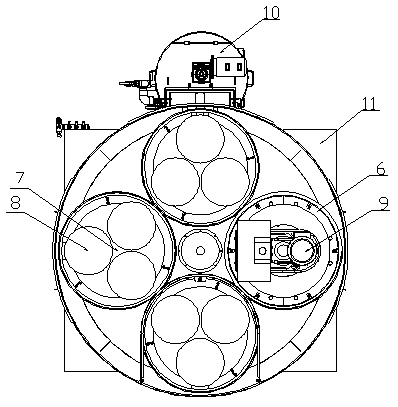

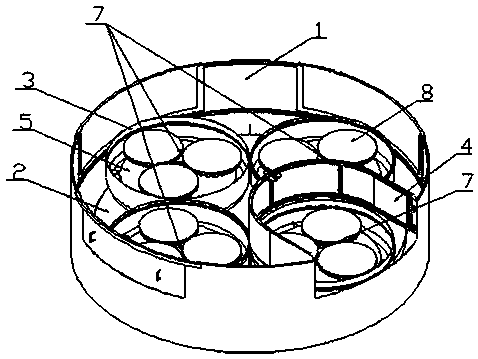

[0022] Referring to the accompanying drawings, a continuous multi-station curved surface polishing machine sand liquid circulation and protection device includes 4 station units 7, one of which is a loading and unloading station, and the remaining 3 station units 7 are Working station, each station unit 7 includes three rotary assemblies 8, the rotary assembly 8 passes through the hole corresponding to the station liquid shield 5 (the station liquid shield 5 is the prior art), and the station The station liquid retaining cover 5 is installed correspondingly to the station liquid receiving basin 3 (the station liquid receiving basin 3 is the prior art), and the outer edge of the station liquid retaining cover 5 is placed in the station liquid receiving basin 3. The station unit 7 corresponds to the upper plate unit 9, and the upper plate liquid shield 6 of the upper plate unit 9 is vertically facing the liquid receiving basin 3 of the station. When working, the upper plate liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com