Plywood assembling machine for plywood machining based on vortex air exhaust drying theory

A technology of plywood and jigsaw machine, which is applied to plywood presses, veneer presses, wood processing equipment, etc. It can solve problems such as long working time of jigsaw panels, unevenness inside the boards, and affecting the use effect, so as to improve the drying effect , prevent random movement, and achieve the effect of positioning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

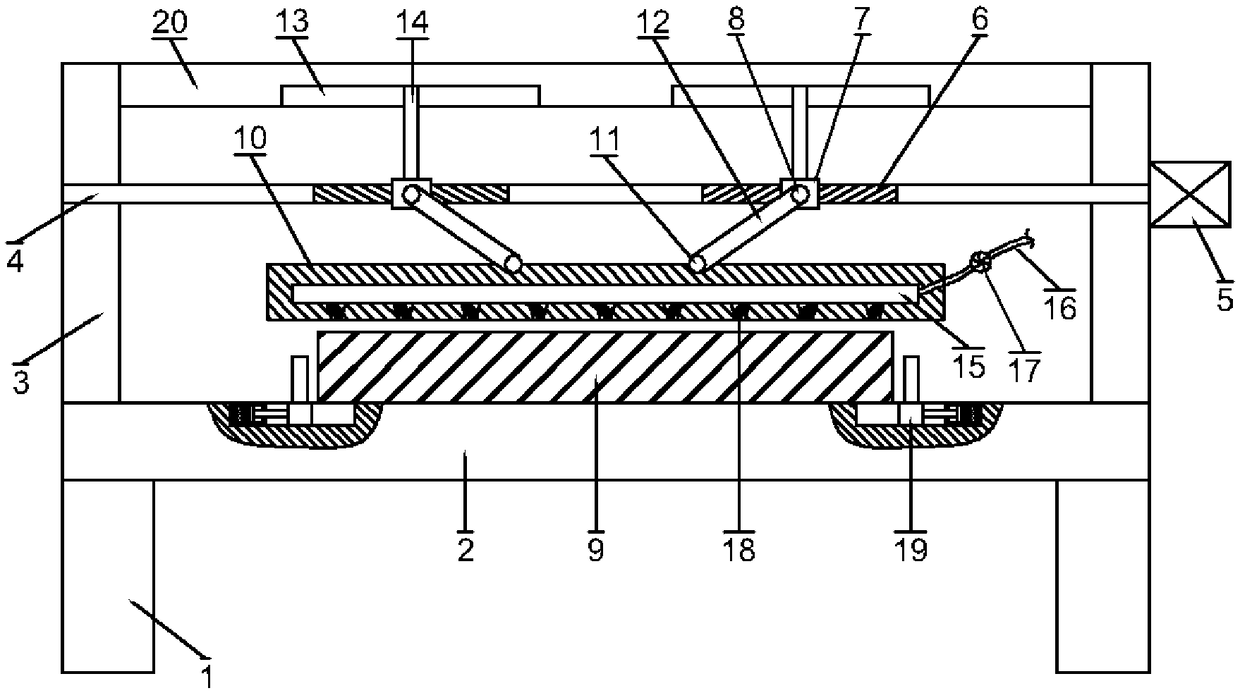

[0021] see figure 1 , in this embodiment, a plywood processing jigsaw machine based on the principle of vortex air drying, including four support legs 1, the tops of the support legs 1 are fixedly connected to the lower platen 2, and the plate 9 is placed on the lower platen 2 Two vertical plates 3 are symmetrically fixedly connected to both sides of the lower pressing plate 2, and a rotating shaft 4 is rotationally connected between the two vertical plates 3, and the right end of the rotating shaft 4 is fixedly connected to the output shaft of the motor 5, and the rotating shaft 4 is symmetrically provided with Two sections of threaded sections 6, the screw threads of the two sections of threaded sections 6 are opposite in direction, and threaded sliders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com