Mining touch sensor

A technology of touch sensor and vibration sensor, which is applied in the field of sensors, can solve the problems of twisting and disconnecting wires, affecting induction, and failure of sensor water ingress performance, etc., and achieves the effects of prolonged service life, wide sensing range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

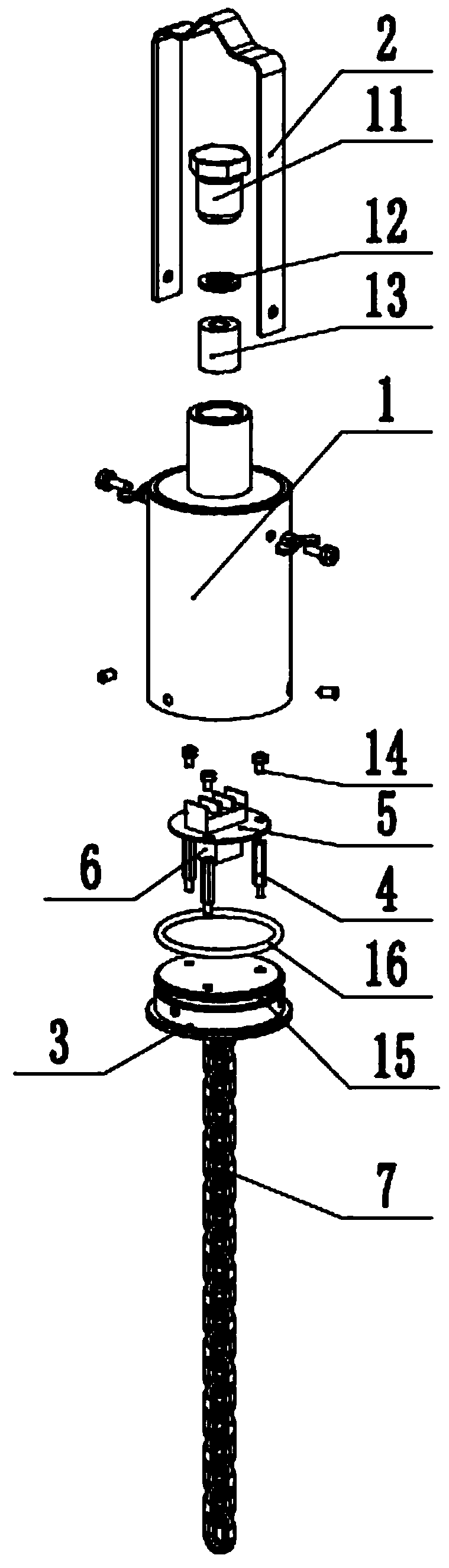

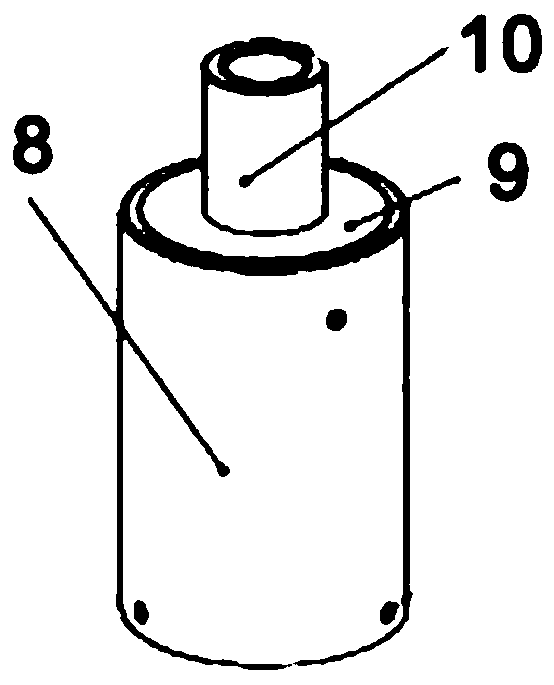

[0017] The present invention is a mining touch sensor, the structure of which is as follows: figure 1 As shown, it includes the main housing 1, the upper part of the main housing 1 is connected with the handle 2, the main housing 1 and the handle 2 are fixedly connected through the wing nut and the first Phillips screw, and the bottom of the main housing 1 is tightened by the inner hexagon The base 3 is fixedly connected with the set screw or the second Phillips screw, the outer wall of the base 3 is attached to the inner wall of the main housing 1, the side wall of the base 3 is provided with a sealing groove 15, and a second sealing ring 16 is arranged in the sealing groove 15, and the base 3. The circuit board 5 is connected to the stud 4. The stud 4 is a single-pass hexagonal copper stud. The circuit board 5 is provided with a screw 14 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com