Automatic compensation hydrogen chloride generator

An automatic compensation, hydrogen chloride technology, applied in chlorine/hydrogen chloride, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low reaction rate, uneven temperature distribution, small contact area, etc., and achieve accelerated input speed and uniform temperature distribution. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

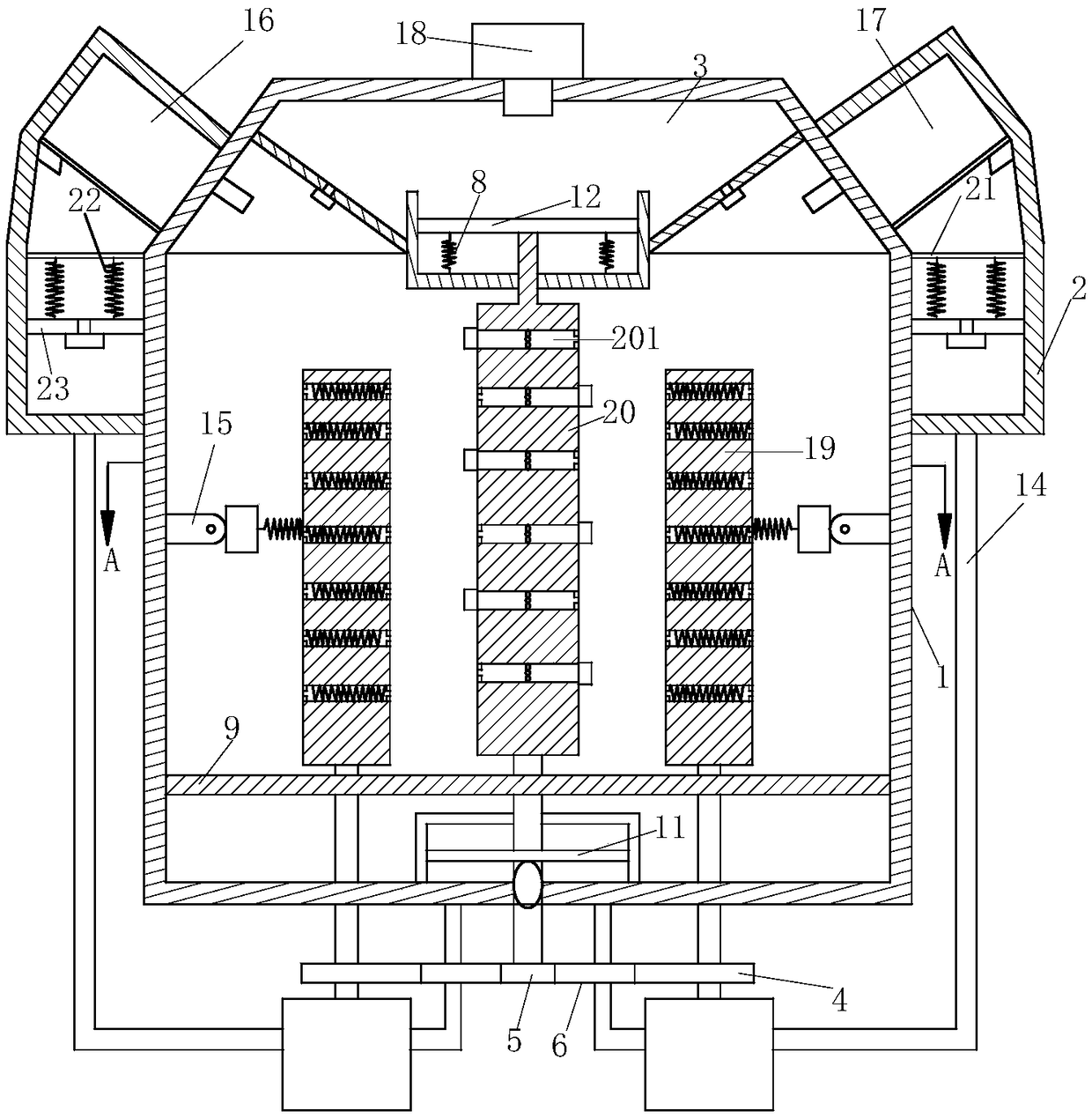

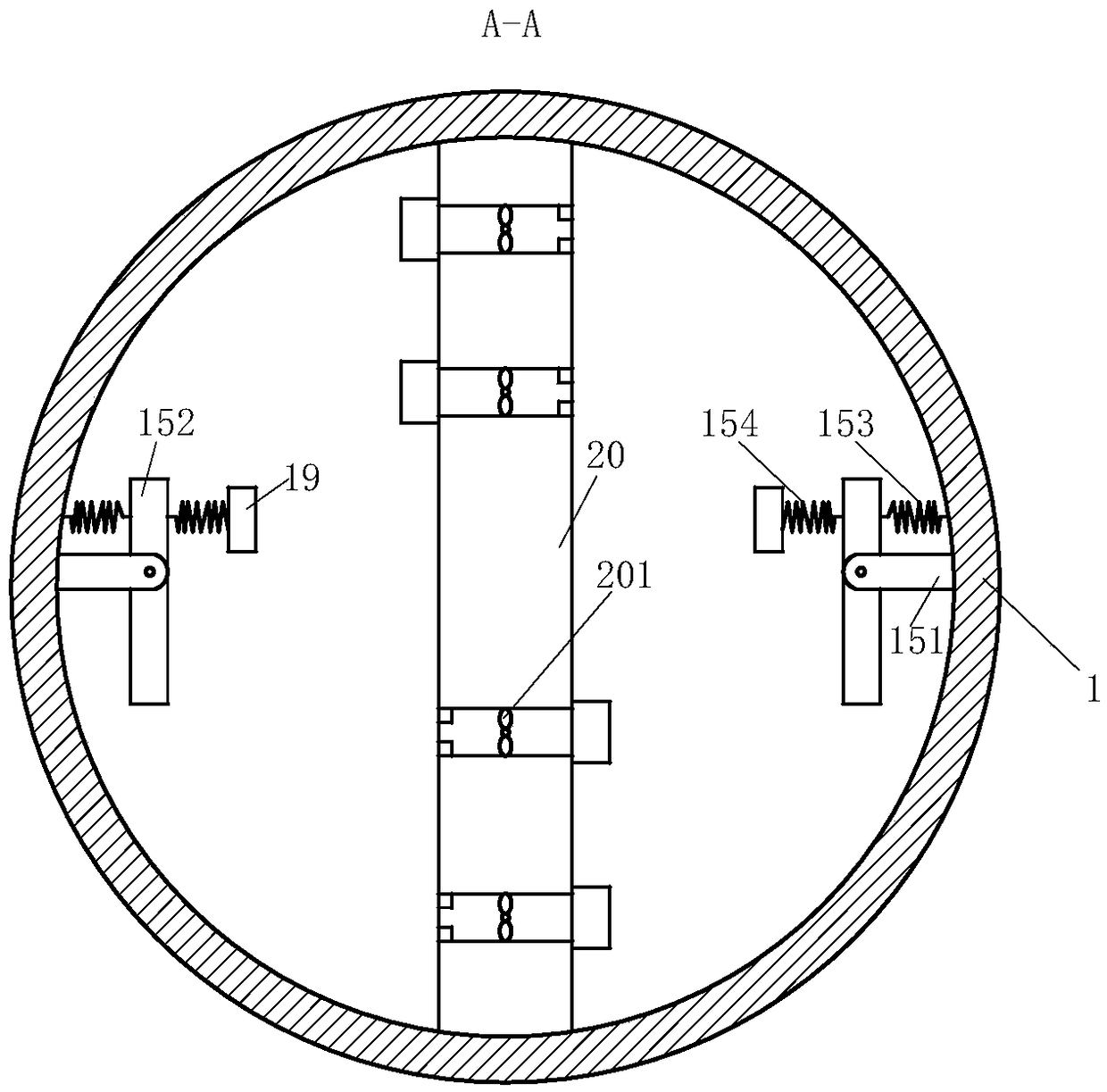

[0022] As an embodiment of the present invention, the stirring plate 20 includes a limit block, a one-way valve and a propeller 201; the stirring plate 20 is evenly provided with small holes, the number of which is not less than six, and one end of the small hole A one-way valve is provided, the other end of the small hole is provided with a limit block, and the inlet ends of the small holes are alternately distributed on both sides of the stirring plate 20; the propeller 201 is placed in the small hole. When working, the reactant enters the small hole from the end where the one-way valve is installed, and the reactant flows out of the small hole from the end with the limit block; when the stirring plate 20 rotates, it is close to the one-way valve on the side of the No. Concentrated sulfuric acid is fed in, and the concentrated sulfuric acid flows to the side of the hydrochloric acid; when the stirring plate 20 rotates, it is close to the check valve on the side of the No. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com