Controlled-release dosing device and oil field water injection well opening tail end unpowered controlled-release sterilizing method

A dosing device and slow-release technology, which is applied in the field of slow-release dosing devices, can solve problems such as inability to continuously dosing, injection water quality not up to standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

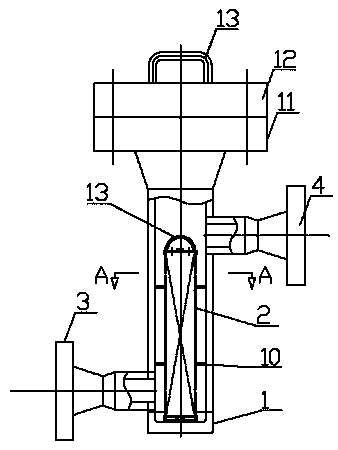

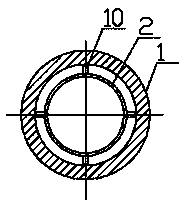

[0021] Embodiment 1: as attached Figures 1 to 3 As shown, the slow-release dosing device includes a drug storage cylinder 1 closed all around, and a drug addition cylinder 2 with an outer diameter smaller than the inner diameter of the drug storage cylinder 1 and closed around it is fixed in the drug storage cylinder 1. A water outlet is provided on the wall of the drug storage cylinder 1 above the drug cylinder 2, and a water inlet corresponding to the lower part of the drug addition cylinder 2 is provided on the wall of the drug storage cylinder 1 opposite to the water outlet; Through holes are distributed on the cylinder wall and the top surface of the cylinder body 2 .

[0022] Usually, the water inlet short-circuit 3 is set at the water inlet, and the water outlet short-circuit 4 is set at the water outlet. The through hole here is used as a water inlet hole and a medicine outlet hole.

[0023] When the slow-release dosing device is used, it is directly connected in se...

Embodiment 2

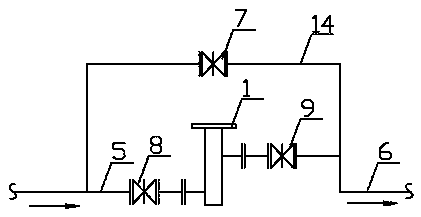

[0037] Embodiment 2: as attached figure 1 As shown, the slow-release dosing device described in the above-mentioned embodiment is used to carry out the unpowered slow-release sterilization method at the end of the oilfield water injection wellhead, and it is carried out as follows: bromochlorhydantoin capsules are housed in the dosing cylinder body 2, and the bromine-chlorhydantoin capsules will be housed. The dosing cylinder 2 of the chlorhydantoin capsule is fixed in the medicine storage cylinder 1, and the medicine storage cylinder 1 is connected in series to the water injection pipeline of the water injection well through the water inlet pipeline 5 and the water outlet pipeline 6, and the injected water in the water injection pipeline of the water injection well Enter the drug storage cylinder 1 through the water inlet, and the injection water in the drug storage cylinder 1 forms a high-pressure swirl on the outer wall of the dosing cylinder 2, and continuously impacts and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com