Multicolor anti-static foaming polypropylene bead particle and preparation method thereof

A foamed polypropylene, a colorful technology, applied in the field of EPP beads, can solve the problems of poor appearance and uneven surface color of colorful beads, achieve uniform appearance and color, solve the difficulty of steam forming, and ensure the appearance color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

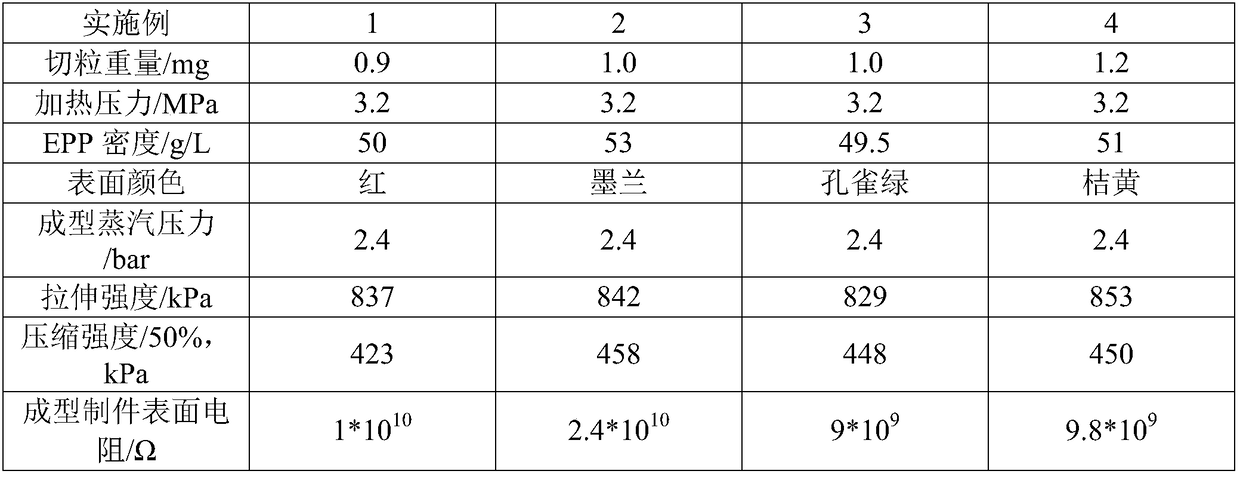

Examples

Embodiment 1

[0032] An antistatic red EPP bead, its formula contains 60% of PP resin by weight; 5% of red color masterbatch, 5% of antistatic functional additive, 1% of antioxidant, 2% of inorganic lubricant, metal Foaming aid 0.1%, PE wax ≤ 5%, and appropriate amount of foaming nucleating agent and stabilizer; the color masterbatch is composed of toner, PP resin carrier and PE wax. The coloring strength of the color masterbatch is 95-105%, the total color difference is ≤1.0, the water content is ≤0.15%, the migration resistance is greater than or equal to 4, the heat resistance is ≥4 grades, the melting index is within 13-17, and the allowable amount of color point> 1.0mm is 0, and the allowable amount of color point is ≤5 / m when it is 0.6-1.0mm 3 Below, the degree of dispersion is within 1-3 pieces / 100mm*100mm.

[0033] Wherein the antioxidant is composed of antioxidant 1010 and antioxidant 1076 according to the mass ratio of 1:1; the inorganic lubricant includes the following component...

Embodiment 2

[0040] An antistatic dark blue color EPP beads, its formula contains 60% of PP resin by weight; dark blue color masterbatch 6%, antistatic functional auxiliary agent 12%, antioxidant 3%, inorganic lubricant 3% , metal-based foaming aid 5%, PE wax ≤ 5%, and appropriate amount of foaming nucleating agent and stabilizer; the color masterbatch is composed of toner, PP resin carrier and PE wax. The coloring strength of the color masterbatch is 95-105%, the total color difference is ≤1.0, the water content is ≤0.15%, the migration resistance is greater than or equal to 4, the heat resistance is ≥4 grades, the melting index is within 13-17, and the allowable amount of color point> 1.0mm is 0, and the allowable amount of color point is ≤5 / m when it is 0.6-1.0mm 3 Below, the degree of dispersion is within 1-3 pieces / 100mm*100mm.

[0041] Wherein the antioxidant is composed of antioxidant 1010 and antioxidant 168 according to the mass ratio of 1:2; the inorganic lubricant includes the ...

Embodiment 3

[0048] A kind of antistatic malachite green EPP beads, which comprises 67% of PP resin by weight in its formula; 15% of malachite green masterbatch, 8% of antistatic functional auxiliary agent, 2% of antioxidant, 4% of inorganic lubricant, metal It is foaming aid 2%, PE wax ≤ 5%, foaming nucleating agent and stabilizer in appropriate amount; the color masterbatch is composed of toner, PP resin carrier and PE wax. The coloring strength of the color masterbatch is 95-105%, the total color difference is ≤1.0, the water content is ≤0.15%, the migration resistance is greater than or equal to 4, the heat resistance is ≥4 grades, the melting index is within 13-17, and the allowable amount of color point> 1.0mm is 0, and the allowable amount of color point is ≤5 / m when it is 0.6-1.0mm 3 Below, the degree of dispersion is within 1-3 pieces / 100mm*100mm.

[0049] Wherein the antioxidant is composed of antioxidant 1076 and antioxidant 168 according to the mass ratio of 3:2; the inorganic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com