Textile machines that produce take-up packages

A textile machine and bobbin technology, applied in the field of textile machines, can solve problems such as station or textile machine shutdown, plastic deformation, control valve failure, etc., and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

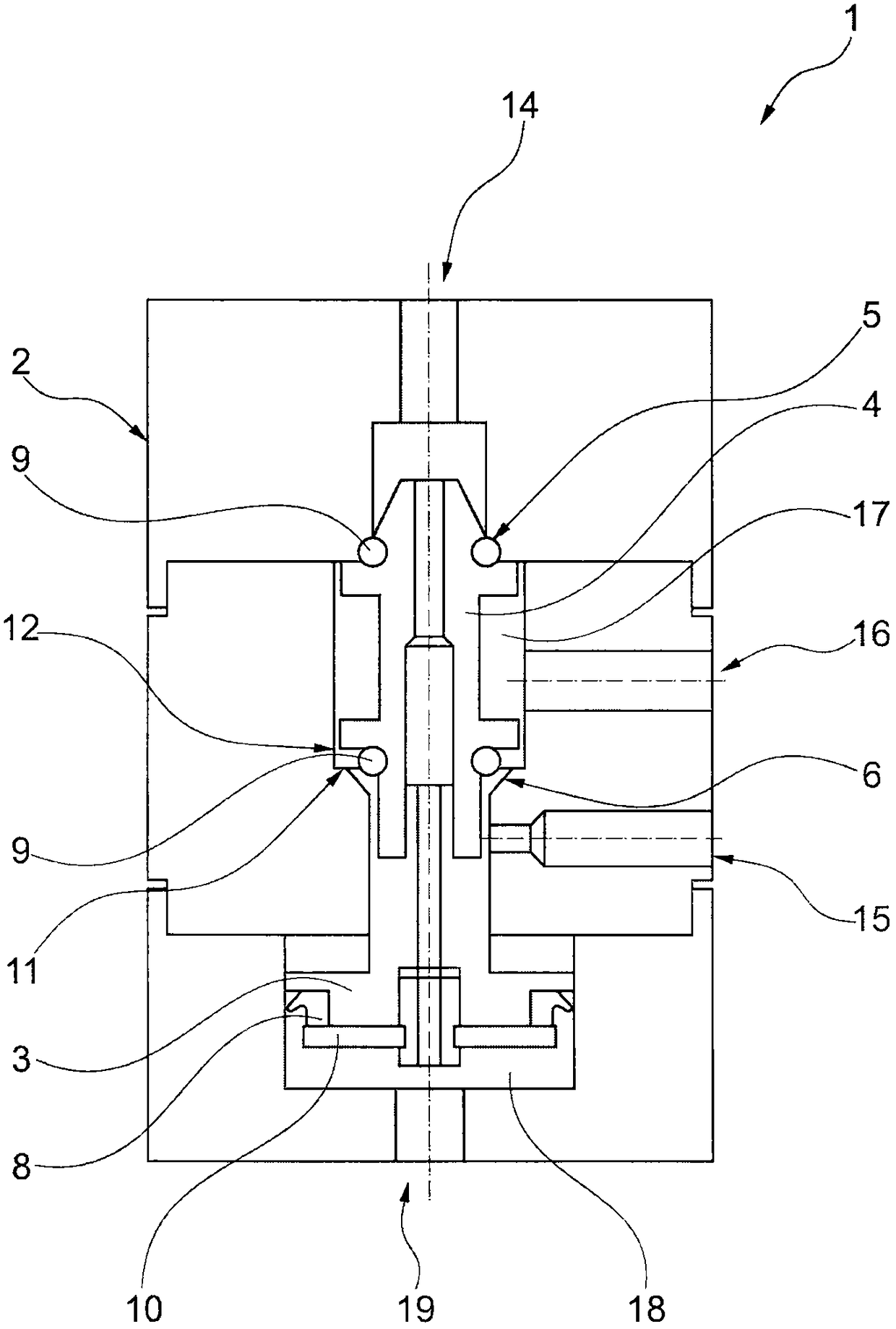

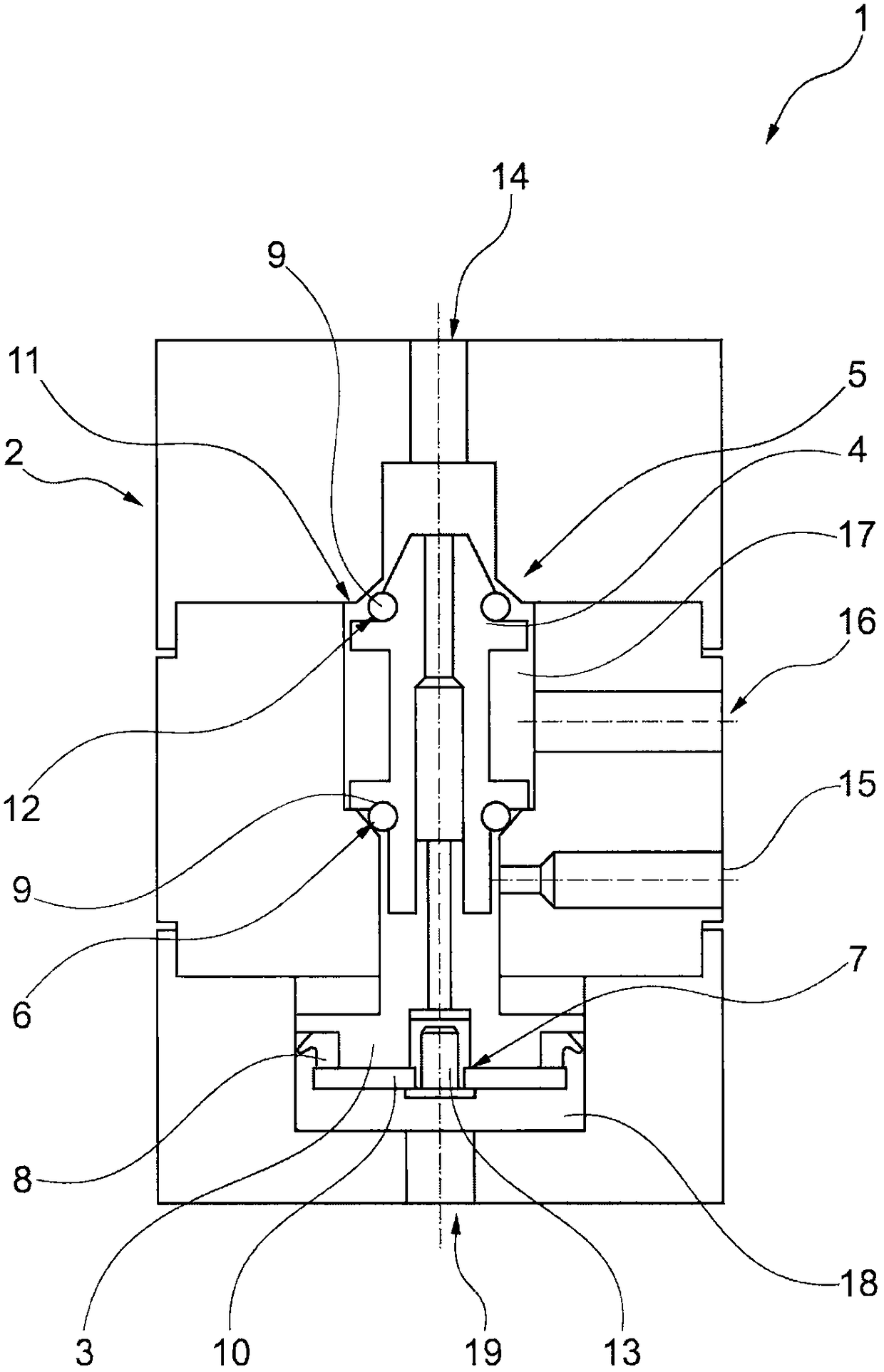

[0061] exist figure 1 The structure of the control valve 1 is shown in a schematic diagram as an example, and the front sealing seat 5 is closed at this time.

[0062] The control valve 1 includes a valve body 2 , a piston 3 and a push rod 4 . Below the piston 3 , a piston seal 8 separates the two air circuits or the front chamber 17 and the rear chamber 18 .

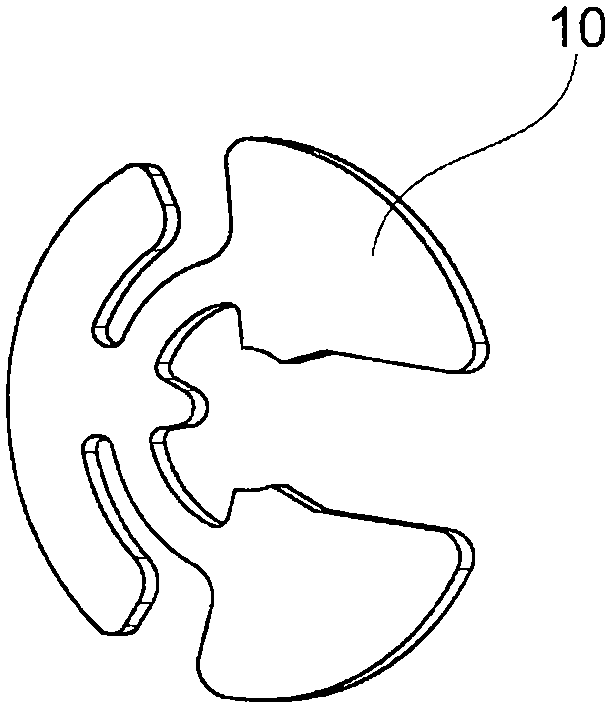

[0063] A support 10 is again arranged below the piston seal 8 . Via the support 10 , not only the piston 3 is fastened to the plunger 4 , but also the piston seal 8 is fastened to the piston 3 .

[0064] In addition, in this embodiment, the valve body 2 is divided into three sections and provided with a plurality of contact surfaces 11 against which respective corresponding surfaces 12 can be abutted, said corresponding surfaces being formed on the front sealing seat 5 and the front sealing seat 5 of the push rod 4 . On the rear sealing seat 6.

[0065] Via the main channel 14 , air flows through a continuous small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com