A V-shaped frame hoisting construction auxiliary equipment and construction method

A kind of auxiliary equipment and frame technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of V-shaped frame self-heaviness, large safety risks, and high lifting height, so as to achieve the effect of improving construction efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

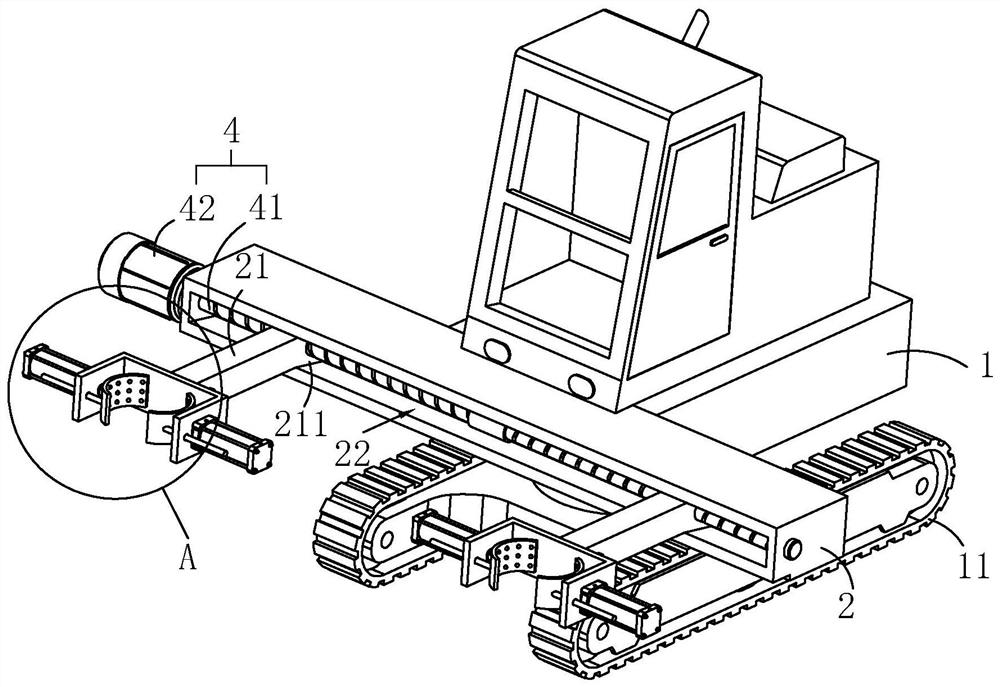

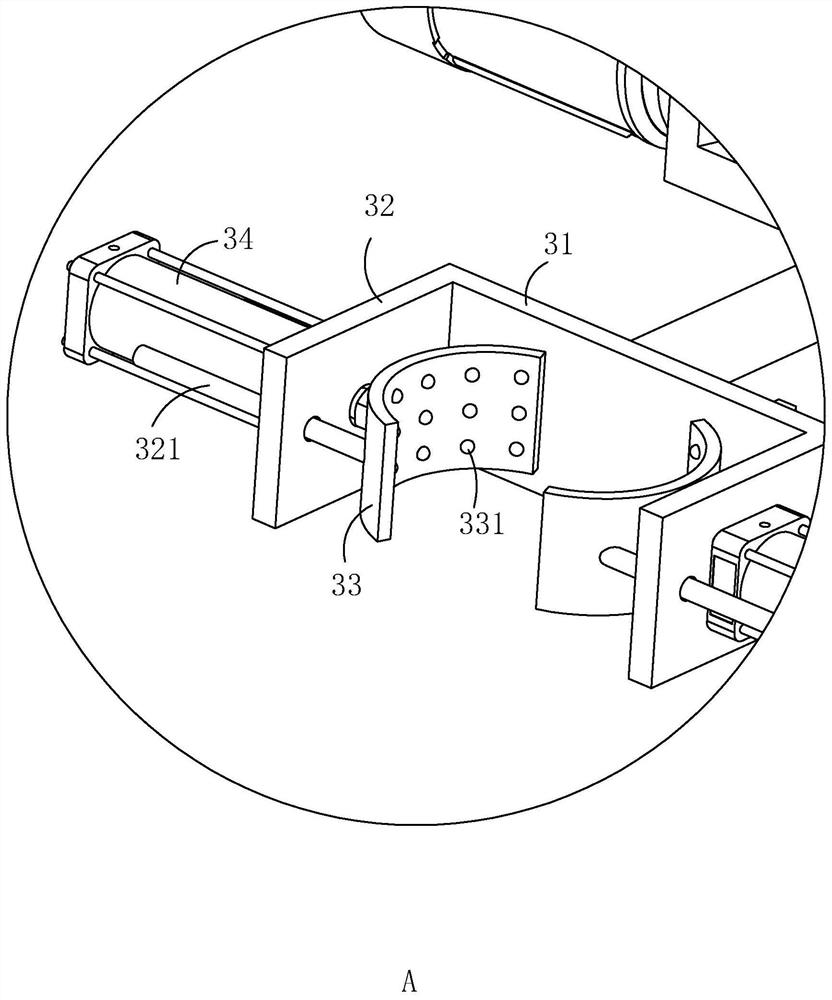

[0038] Such as figure 1 , 3 As shown, a V-shaped frame hoisting construction auxiliary equipment includes a car body 1 and a driving device for driving the car body 1 to travel. The driving device is the same as that of an excavator or a crane. The car body 1 is provided with a chain plate type chassis 11 , to reduce the pressure on the ground, so that the movement of the car body 1 is more stable. The vehicle body 1 is fixedly provided with a mounting beam 2, and the mounting beam 2 is provided with two parallel struts 21, and each strut 21 is provided with a clip for clamping the rod body 51 of the V-shaped frame 5 at one end far away from the vehicle body 1. support components.

[0039] Such as figure 1 As shown, the side wall of the installation beam 2 close to the pole 21 is provided with a chute 22 along its own length direction, and the pole 21 is fixedly provided with a slider 211 slidingly connected to the chute 22, and the chute 22 is set as a dovetail groove. Th...

Embodiment 2

[0046] Such as image 3 Shown, a kind of V-shaped frame hoisting construction method comprises the following steps:

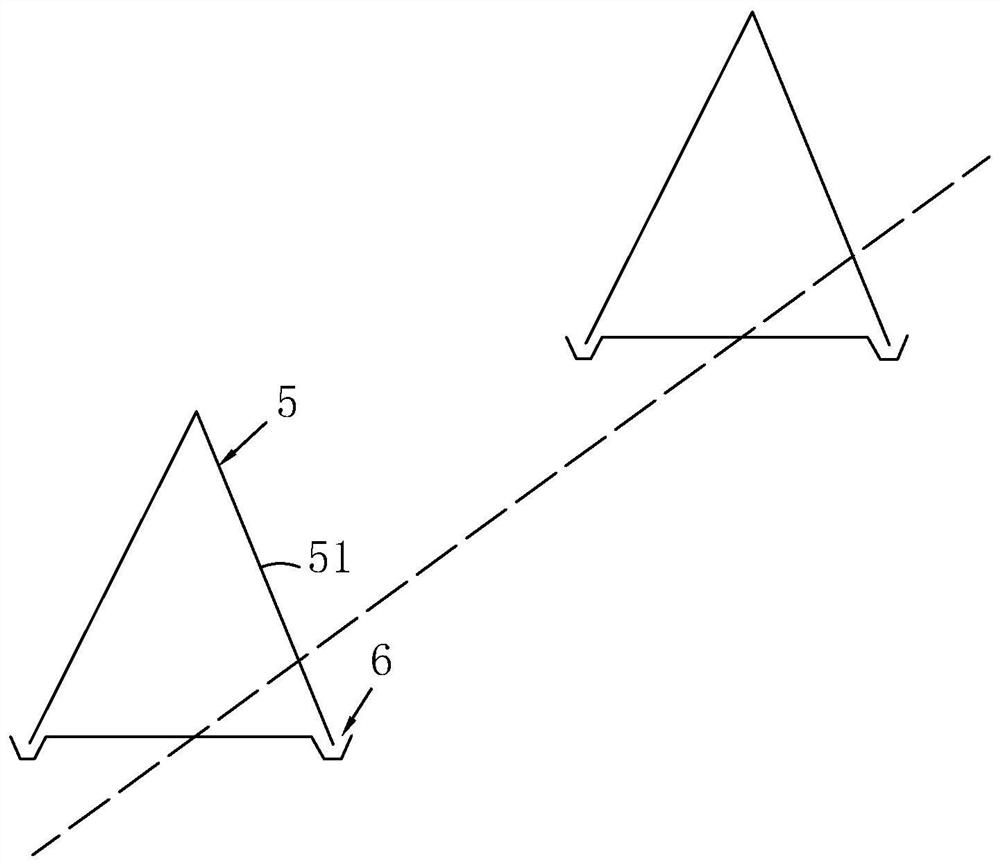

[0047] Step 1: Use concrete pouring to form a concrete base, and set up installation cups 6 on the concrete base. Two installation cups 6 form a group, a total of two groups, and four installation cups 6 are arranged in two rows and two columns. Arrangement, all the bottom surfaces of the cups where the cup mouth 6 is installed are leveled;

[0048] Step 2: Lift the V-shaped frame 5 by a crane, and make the feet of the V-shaped frame 5 higher than the ground;

[0049] Step 3: The V-shaped frame 5 is clamped and positioned by a V-shaped frame 5 hoisting construction auxiliary equipment according to any one of claims 1-8, and the V-shaped frame 5 is moved to the installation cup 6 under the cooperation of the crane directly above;

[0050] Step 4: Lower the V-shaped frame 5 by a crane, keep the V-shaped frame 5 in a vertical state, and pour concrete into the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com