Side mold mechanism for concrete mold spraying

A technology of concrete and side formwork, which is applied in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems of prolonging the construction period, aggravating concrete leakage and waste, etc., and achieves the effect of improving construction quality, improving construction efficiency and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

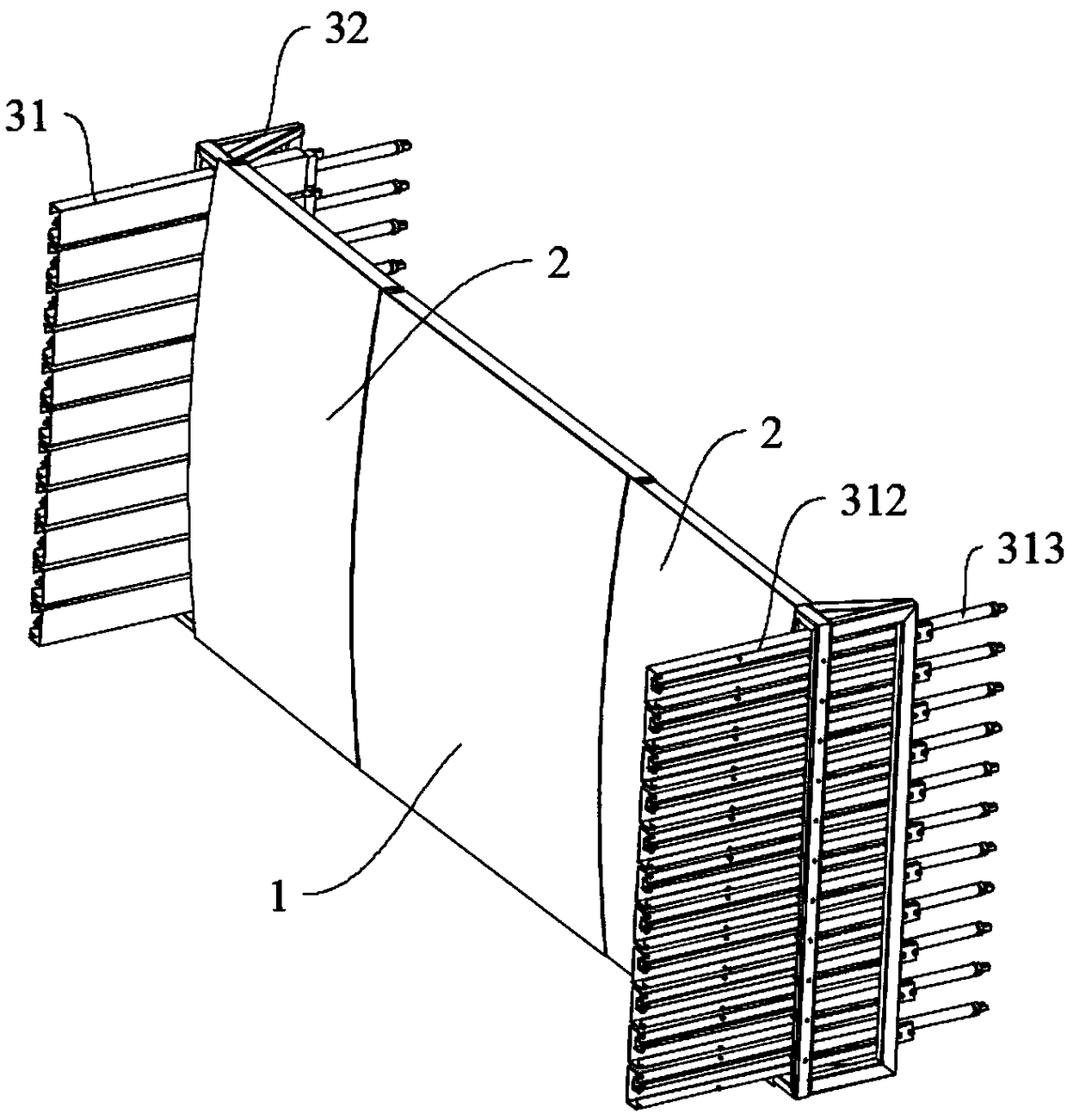

[0032] As shown in the figure, the sideform mechanism 3 for concrete mold spraying includes a sideform support 32 and a telescopic side formwork assembly, the sideform support 32 is fixed on the edge of the formwork, and the sideform assembly is installed on the sideform support 32, and It can expand and contract in the direction perpendicular to the formwork, and the protruding side formwork components can be against the rock surface of the tunnel, so that the rock surface, formwork and side formwork components can cooperate with each other to form a mold cavity.

[0033] The side formwork assembly is composed of several side formwork units 31 arranged continuously, and each side formwork unit 31 can perform independent telescopic movement. The side template unit 31 includes an inner stroke frame 311, a side mold cover 312 and a telescopic mechanism, and the side mold cover 312 is slidably sleeved on the inner stroke frame 311; the telescopic mechanism is configured as an oil ...

Embodiment 2

[0043] An example of applying the side form mechanism 3 in Embodiment 1 to a combined formwork mechanism is disclosed.

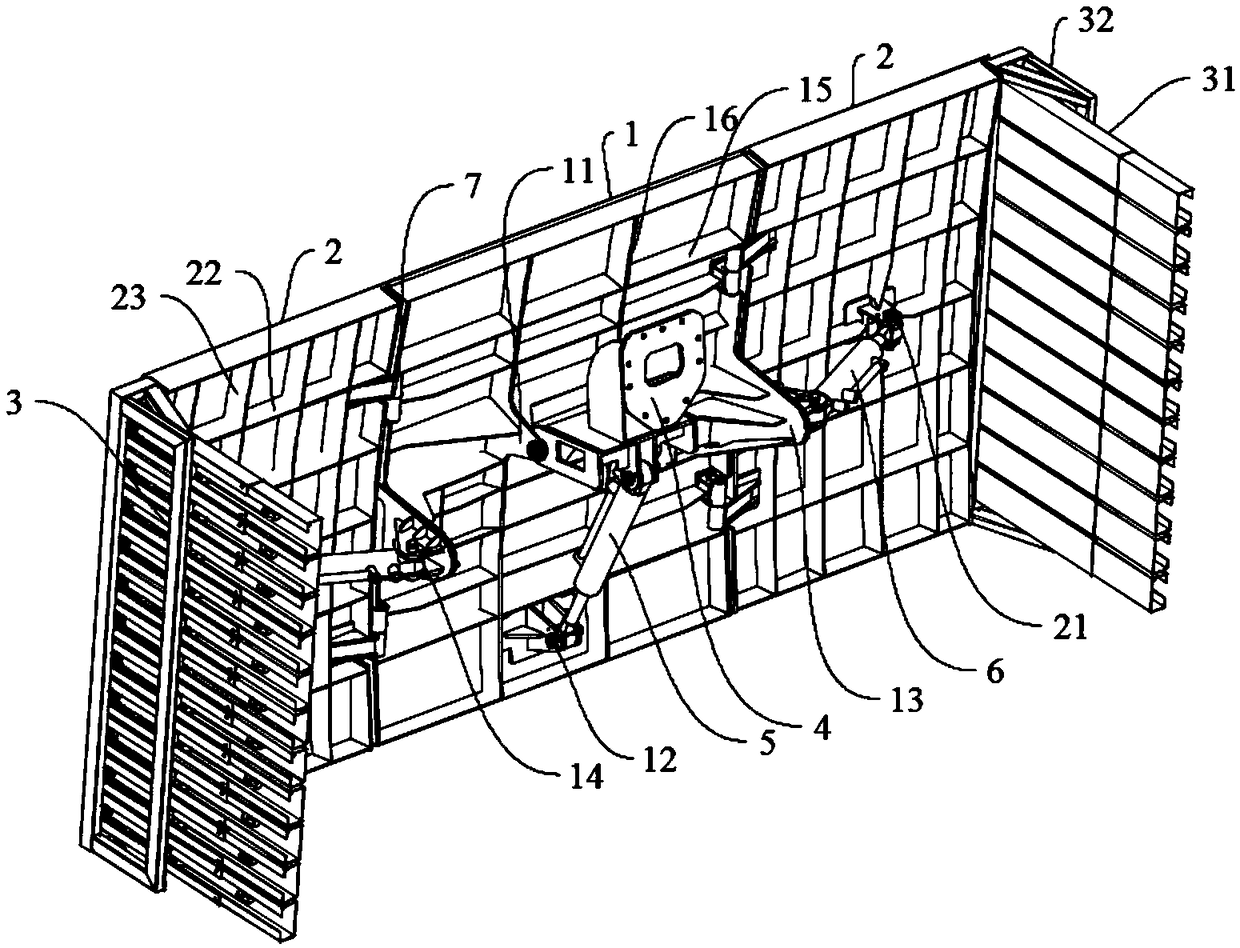

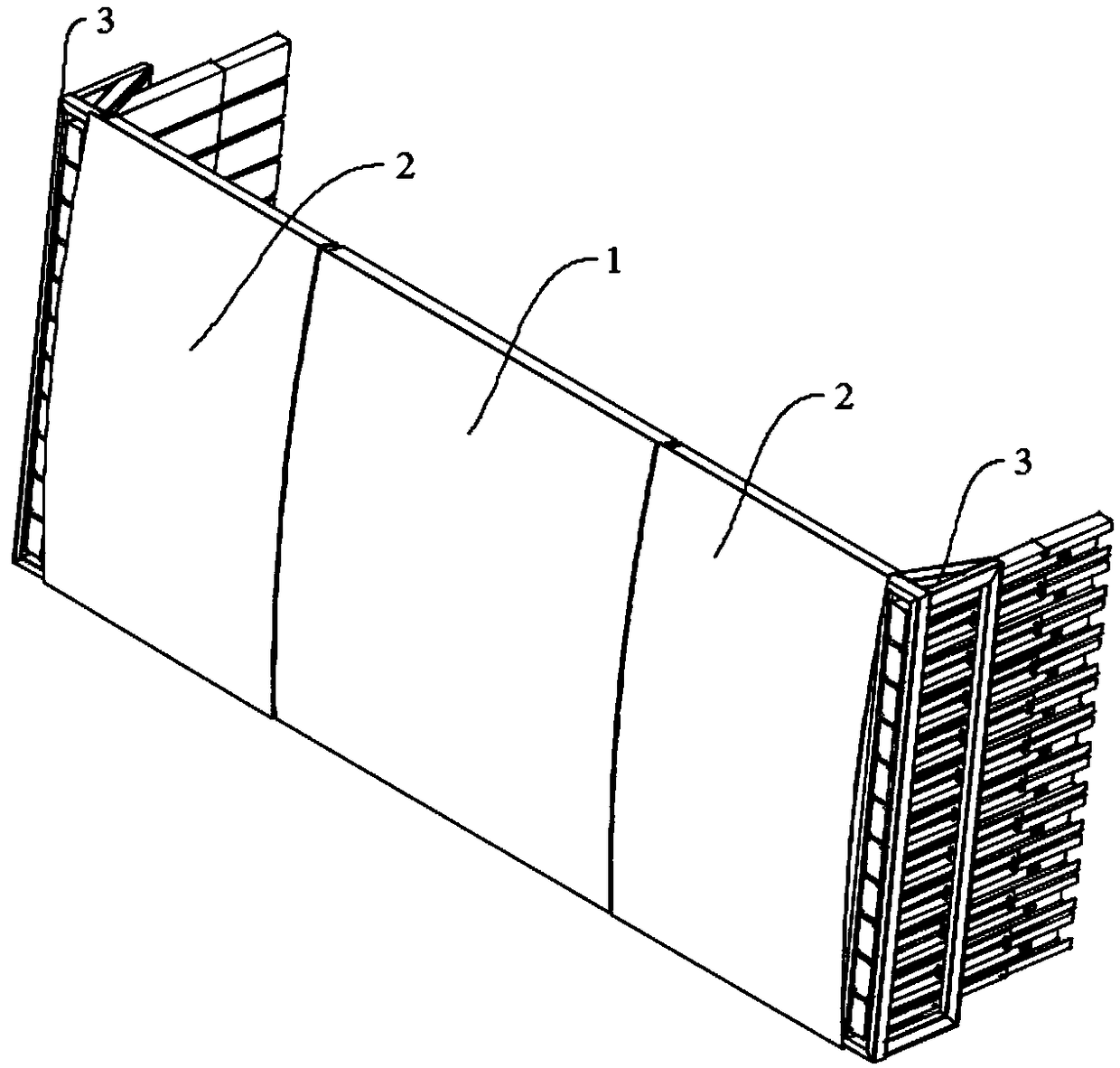

[0044] A combined formwork mechanism for concrete mold spraying, the formwork mechanism includes a main formwork 1, an auxiliary formwork 2, a side formwork mechanism 3, a formwork support 4, a pitch cylinder 5, a side cylinder 6 and a hinge seat 7. One or both sides of the main formwork 1 are foldably connected with the auxiliary formwork 2, and the formwork mechanism can cover more than two adjacent steel arches erected on the tunnel driving surface as a whole at any height; the main formwork 1 and the auxiliary formwork 2 The two sides are connected through the hinge seat 7; the piston rod sub-formwork 2 of the lateral oil cylinder 6 is connected through the hinge support 21, and the backs of both sides of the main formwork 1 are respectively provided with side cylinder hinge seat plates 13 protruding vertically from the main formwork 1. The cylinder body...

Embodiment 3

[0055] In this embodiment, on the basis of Embodiment 2, when the formwork assembly and the sideform mechanism 3 are in use, the steel arch frame must be built independently of the tunnel, that is, when the steel arch frame is not erected, the sideform mechanism 3. The template mechanism and the rock surface directly form a mold cavity for direct injection pouring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com