Dynamic plugging device during shaft kiln distribution

A plugging device and shaft kiln technology, which is applied in the direction of furnaces, vertical furnaces, lighting and heating equipment, etc., can solve high-demand problems, achieve the effects of simple and compact structure, reduce the risk of air leakage, and improve use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

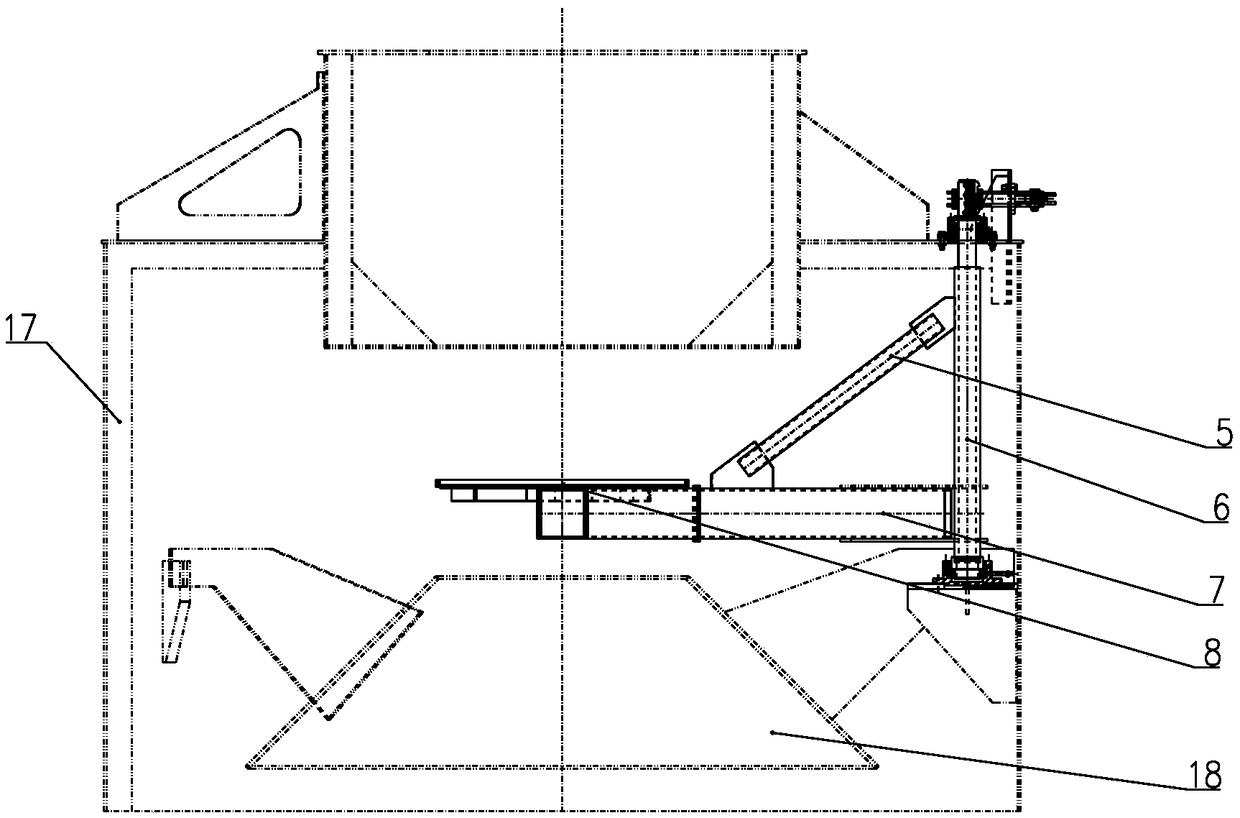

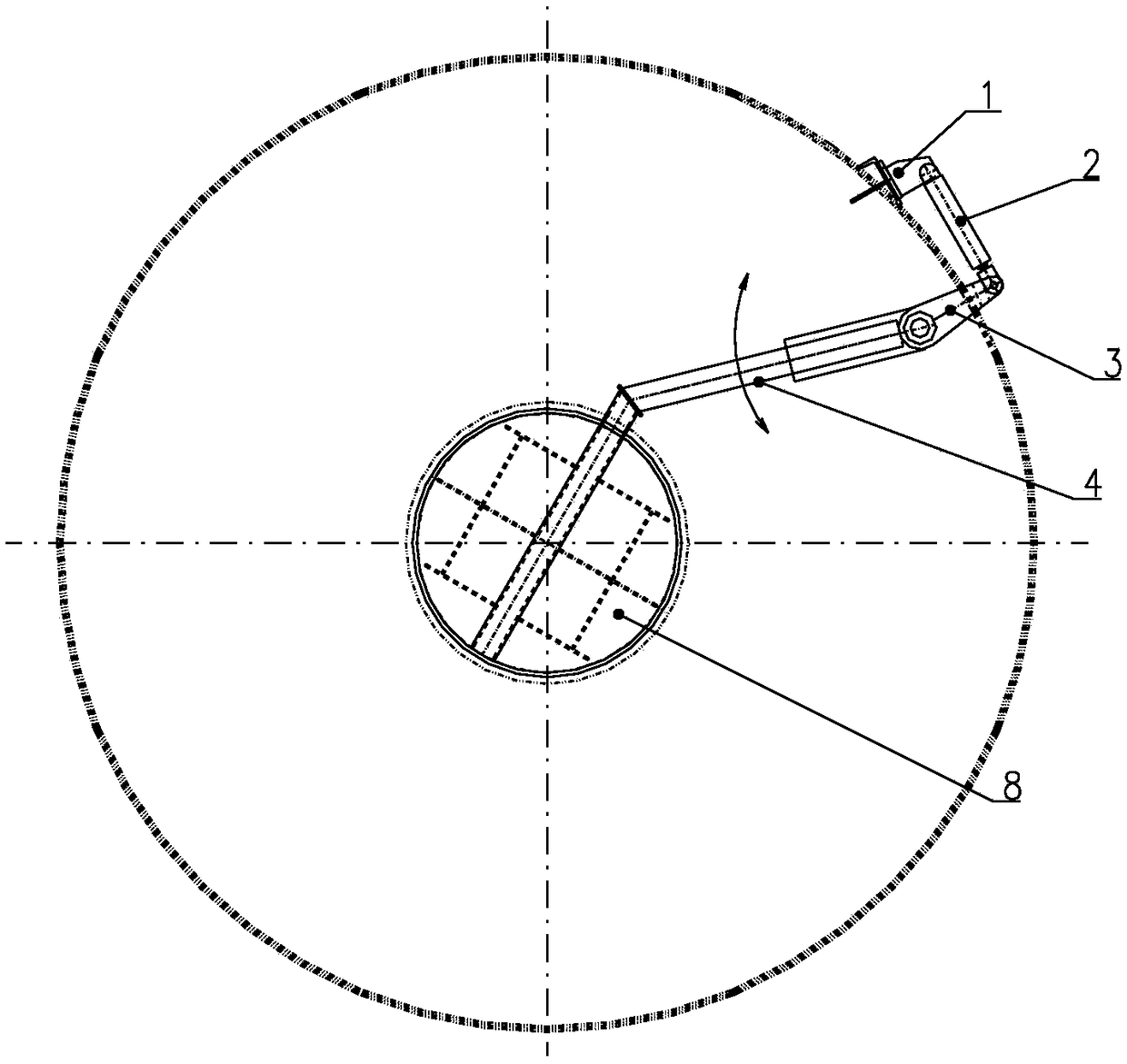

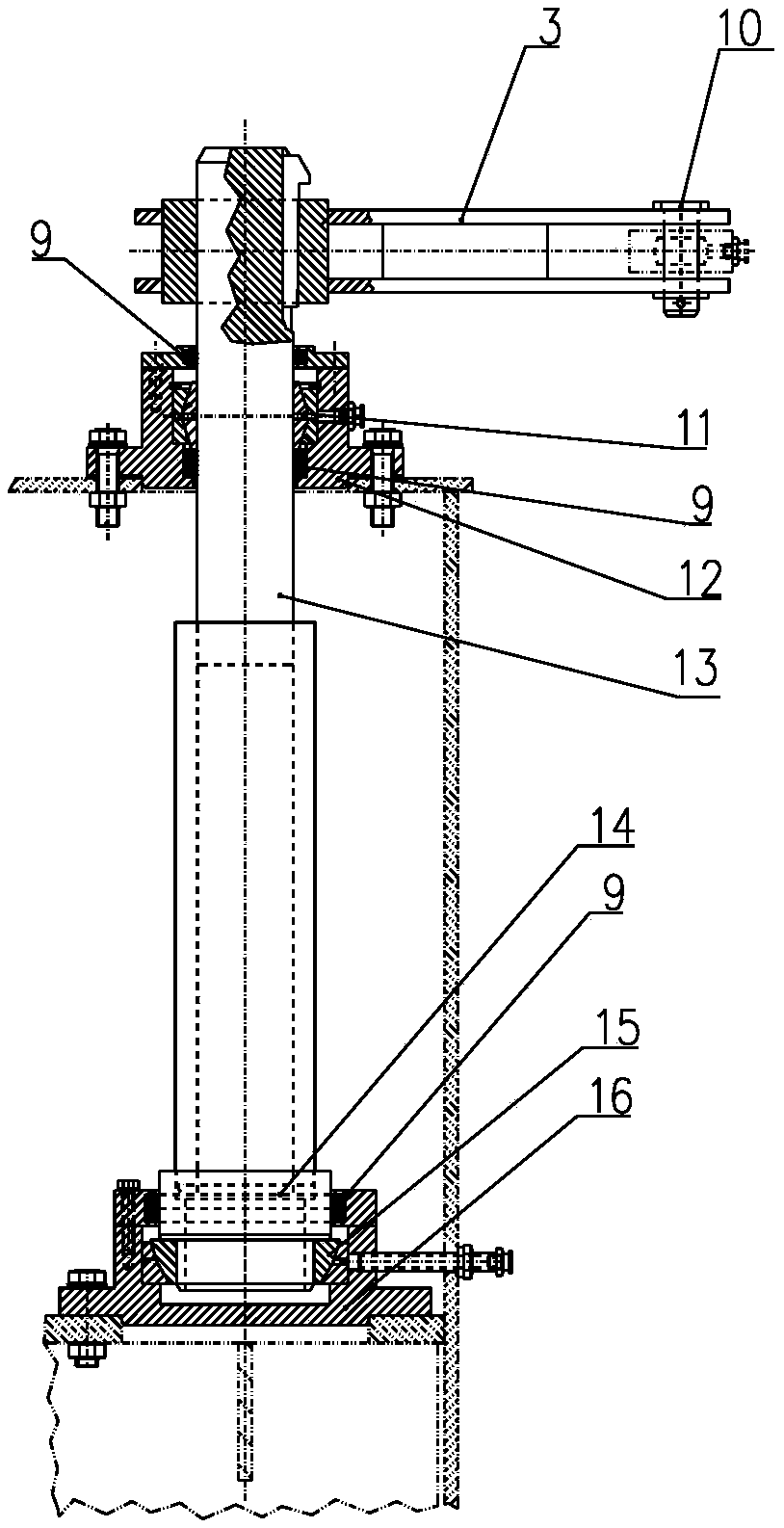

[0024] Such as figure 1 , figure 2 As shown, a dynamic plugging device for vertical kiln material distribution according to the present invention is installed above the conical distributor 18 at the feed inlet of the vertical kiln. Conical cylindrical structure; the dynamic blocking device includes an actuator support 1, a linear actuator 2, a short swing arm 3, a vertical shaft, a bracket 4 and a sealing disc 8; the actuator support 1 is arranged on a vertical On the outer wall of the kiln 17, the tail end of the linear actuator 2 is hinged on the actuator support 1, and the power output end of the linear actuator 2 is hinged to one end of the short swing arm 3 through a pin 10; the short swing arm 3 extends into the kiln body It is connected with one end of the bracket 4, and can drive the bracket 4 to rotate around the vertical axis under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com