Inductance testing device and method for wave-absorbing material

A technology of wave absorbing material and testing device, which is applied in the direction of measuring device, measuring electrical variable, measuring resistance/reactance/impedance, etc., and can solve problems such as poor performance, high brittleness, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

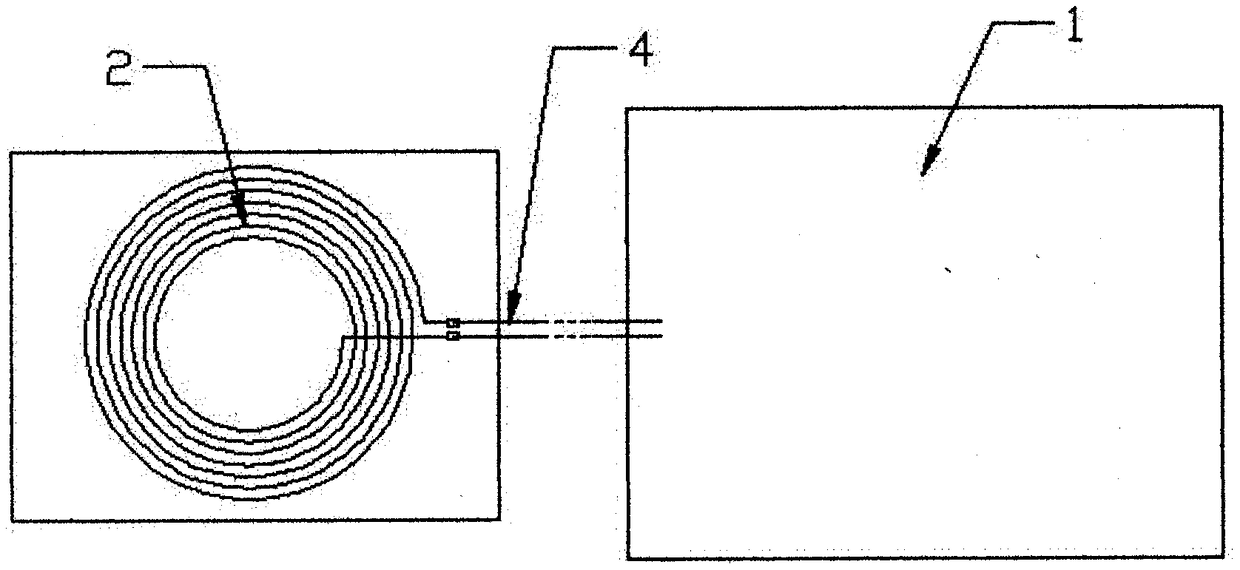

[0028] Such as Figure 1-4 As shown, the inductance testing device of a kind of wave-absorbing material of the present invention is used for detecting the inductance value of its wave-absorbing material, and this device comprises LCR test instrument 1, coil 2 and test jig; The model of described LCR test instrument 1 is Taiwan Goodwill LCR-8110G, the structure and working principle of the LCR testing instrument 1 are prior art, and will not be repeated here; the LCR testing instrument 1 and the coil 2 are connected by a metal wire 4; the coil 2 set in the test fixture;

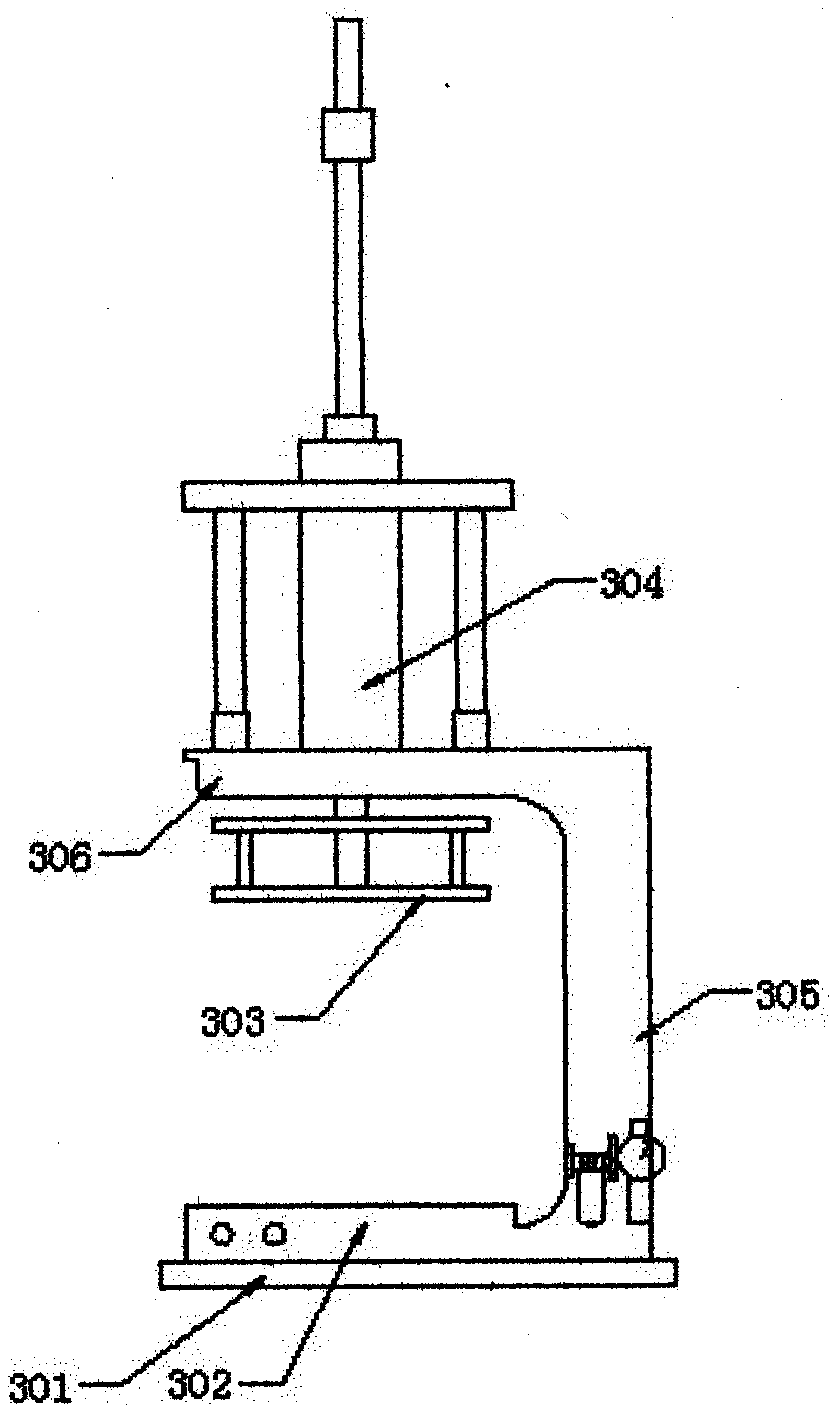

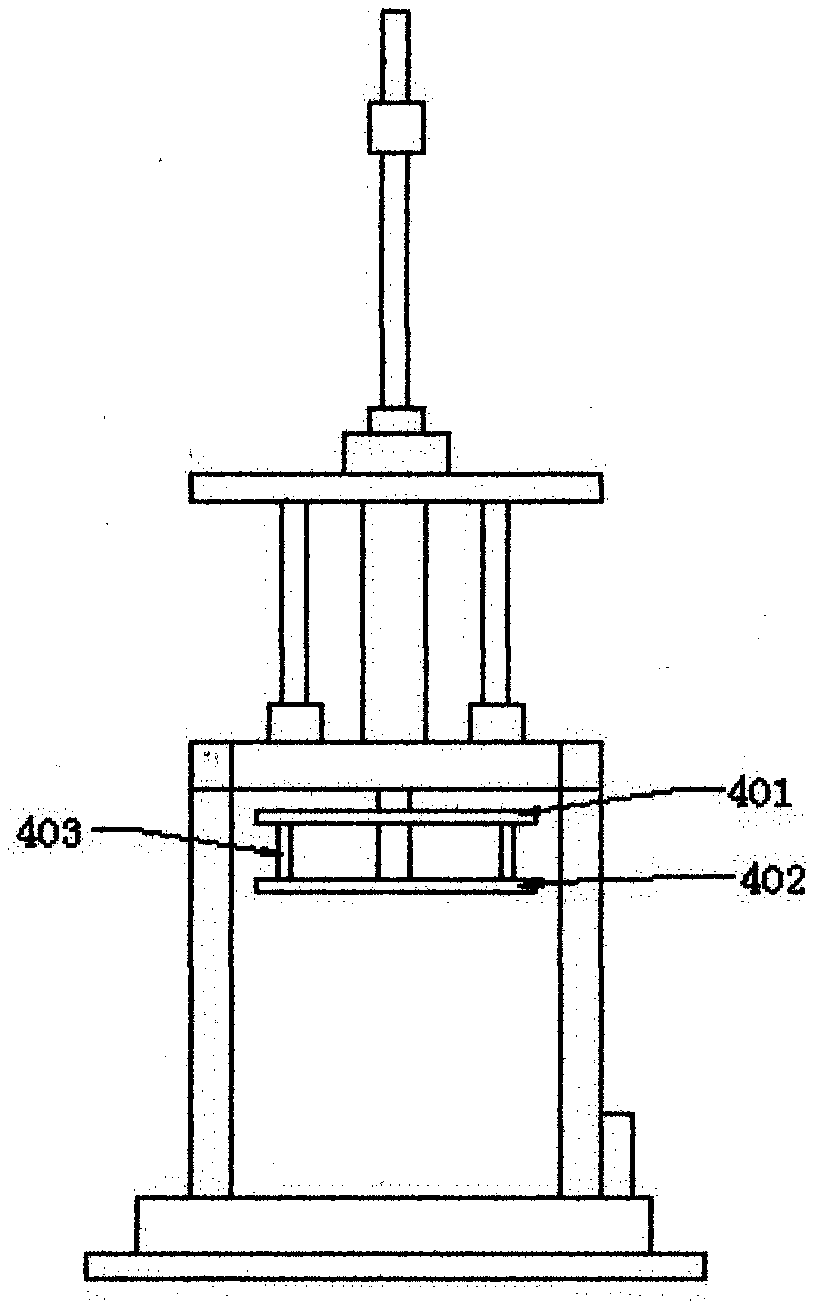

[0029] The test fixture includes a base 301, a lower table 302, an upper platen 303, a lower pressure cylinder 304, a column 305, a top plate 306, a groove 307 and a film 308; the lower table 302 is fixed above the base 301 The base 301 is provided with a fixed bracket behind the lower table surface 302; the fixed bracket includes a column 305 fixedly arranged on the rear end of the base 301 and a top plate 3...

Embodiment 2

[0035] A method for testing the inductance of a wave-absorbing material, comprising the steps of:

[0036] Step 1: Turn on the main power switch of the LCR tester 1, turn on the air pressure switch, set the applied pressure and pressing time, the applied pressure range is 2-5kg / cm2, and the pressing time is 2-5s;

[0037] Step 2: Coil 2 installation: Select a coil 2 with a line width of 1.0-2.0mm, a line spacing of 0.1-0.2mm, a number of turns of 10-20 turns, and a thickness of 1.0-2.0o / z to pass the metal wire 4 and LCR test The instrument 1 is connected, the coil 2 is connected and fixed in the groove 307 of the lower table 302 on the test fixture, and the LCR test instrument 1 is opened;

[0038] Step 3: Put a film 308 with a thickness of 0.10-0.50mm on the lower table 302 of the test fixture, and confirm the inductance Ls value, which is stable at 7.951uh and normal;

[0039] Step 4: Place a piece of microwave-absorbing material of known thickness on the lower table 302 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com